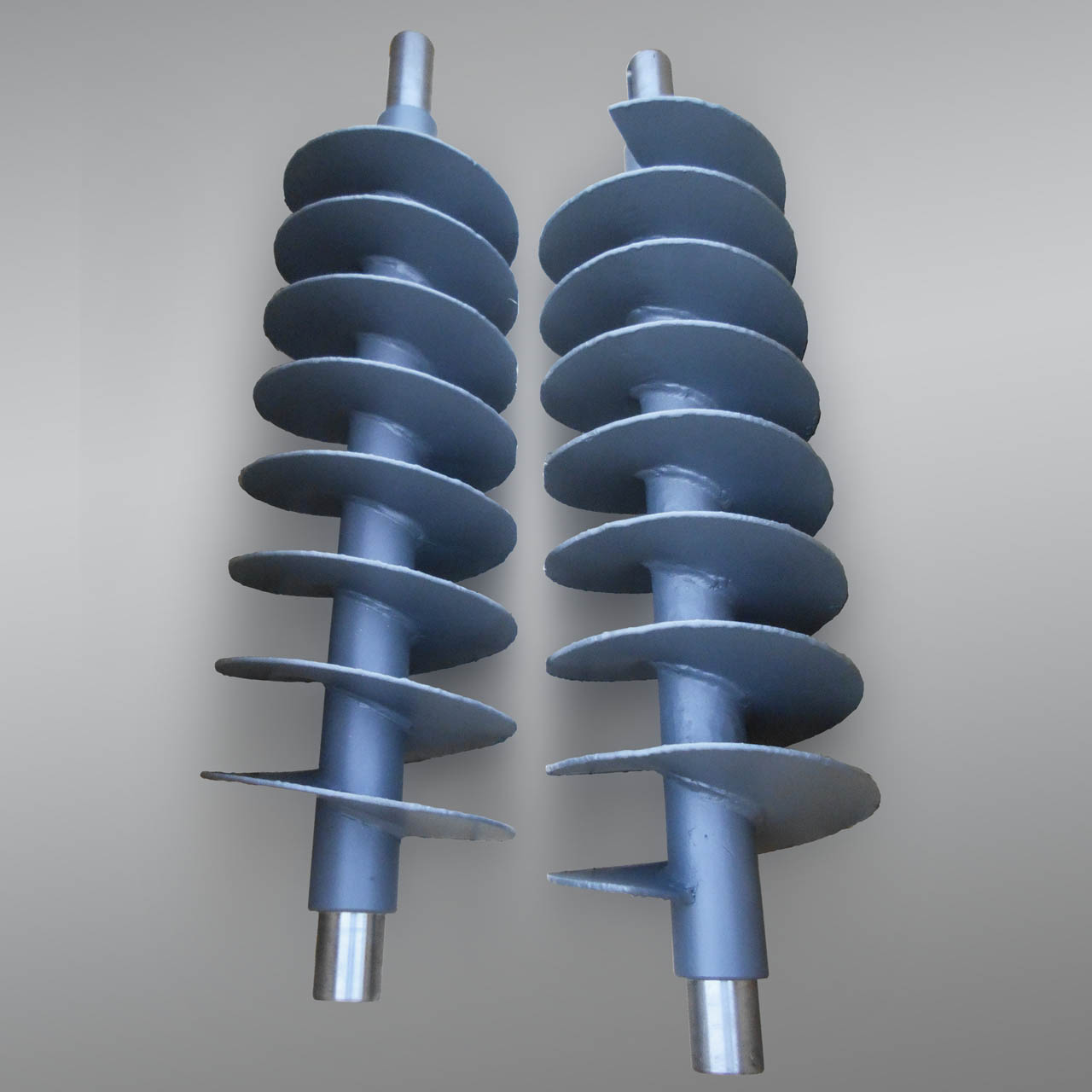

Extruder Augers

We produce Extruder Augers for all types of machinery, fully customized to the specifics of each production process. Depending on the soil quality, we apply different types of hard surfacing to ensure the ideal combination of durability and smooth extrusion.

We also offer hard chrome plating as an alternative solution for screw protection, providing a smooth surface with reduced friction.

Hardfacing Types: Τύποι Σκλήρυνσης

- SF-CROM Hardfacing

- SF-MID Hardfacing

- SF-HARD Hardfacing

- SF-SPECIAL Hardfacing

SF-CROM Hardfacing

Applied with peripheral carbide and full chromium plating.

Ideal for applications with moderate wear conditions.

The triple chrome plating across the screw surface reduces load on the extruder, lowers energy consumption, and maintains high performance.

SF-MID Hardfacing

Peripheral carbide reinforcement, with hardfacing on the front wing surface and reinforced area (80 mm) on the rear.

Designed for medium abrasion conditions, offering long-lasting blade protection and ensuring smooth, efficient extrusion from day one.

SF-HARD Hardfacing

Carbide applied to the perimeter and the front edge of the wing (20 mm), with complete reinforcement of the wing and hub.

Ideal for high-abrasion soils. The extensive coverage of all wear areas maximizes service life. Final polishing of the hardened areas ensures immediate productivity with smooth, even extrusion.

SF-SPECIAL Hardfacing

Same as SF-HARD but uses complex carbides.

Designed for extremely high-abrasion soils, offering superior wear resistance. Special alloyed wires provide extended service life even in the harshest conditions. Final polishing ensures smooth and consistent extrusion from the first use.

Extrusion Augers / Welding Materials

SABO FILIERE specializes in hardfacing extrusion augers and provides a full range of welding materials for high-resistance wear and friction applications.

Thanks to our expertise, we advise clients and propose tailored technical solutions based on:

- base material type

- operating conditions

- and installation requirements

Available Welding Materials

- Standard chromium-coated carbide wires

- Composite carbide wires

- Tungsten carbide ropes for extreme wear applications

Our goal is to maximize the service life and reliability of your equipment, providing not only the raw materials but also technical guidance for the most effective implementation in every case.