Extrusion Dies

Extrusion Dies’ manufacturing for bricks and roof tiles is the core activity of SABO FILIERE.

With over 25 years of experience, we deliver high – quality, long lasting products tailored to each production process.

Our specialized team supports every customer by optimizing the extrusion process and maximizing efficiency.

Product CategoriesΚατηγορίες

- Hollow Bricks

- Thermal Insulated Blocks

- Solid and Facing Bricks

- Split Tiles

- Tiles

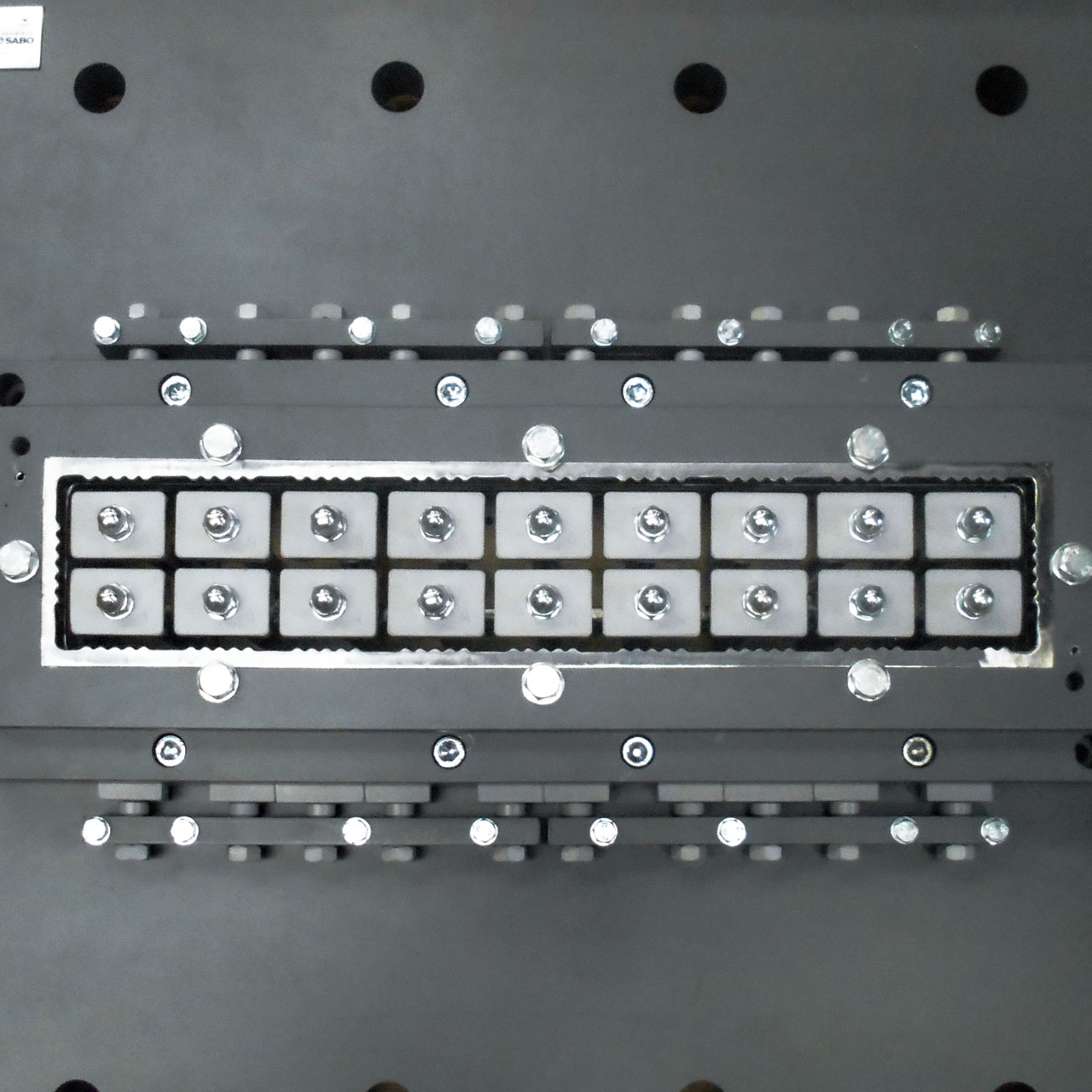

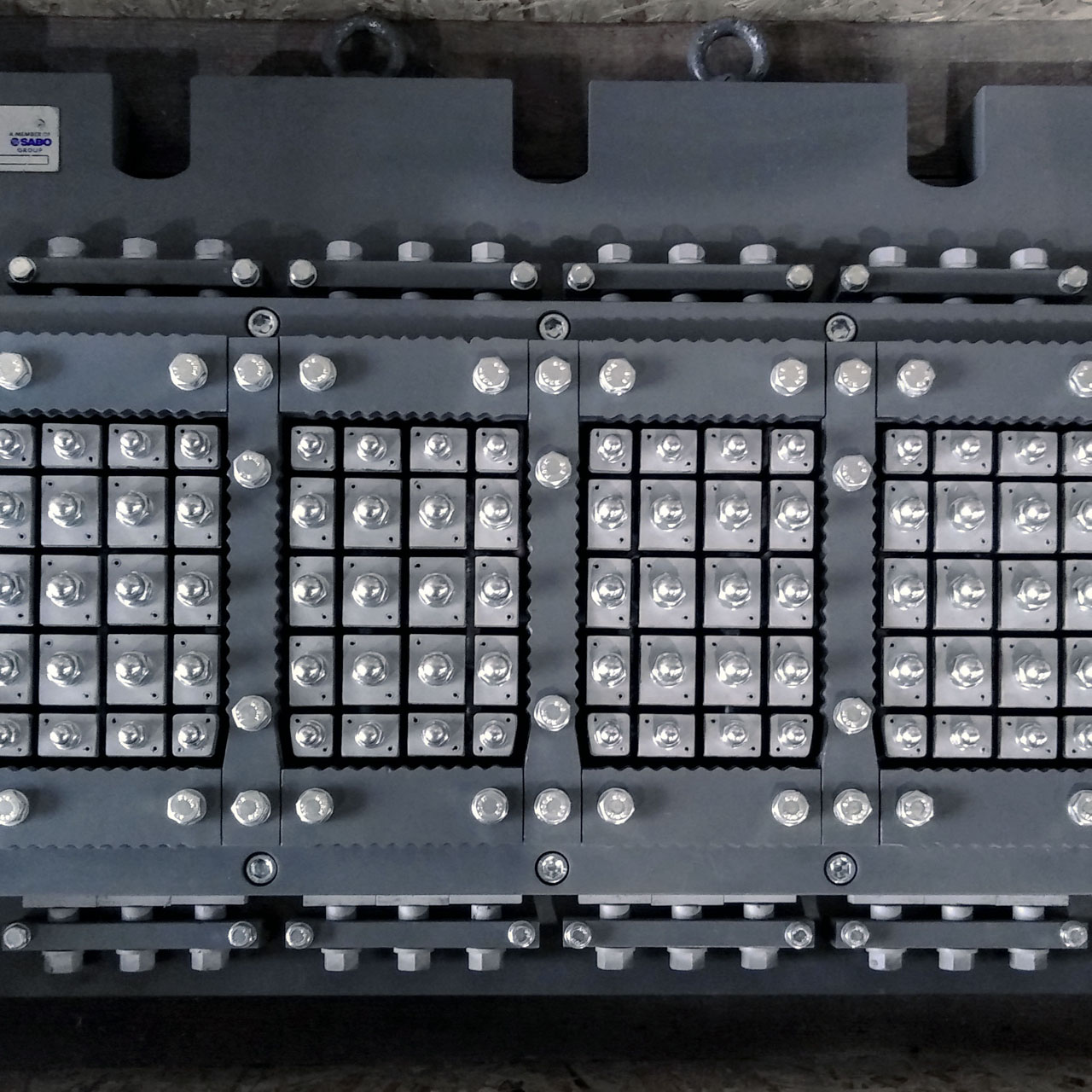

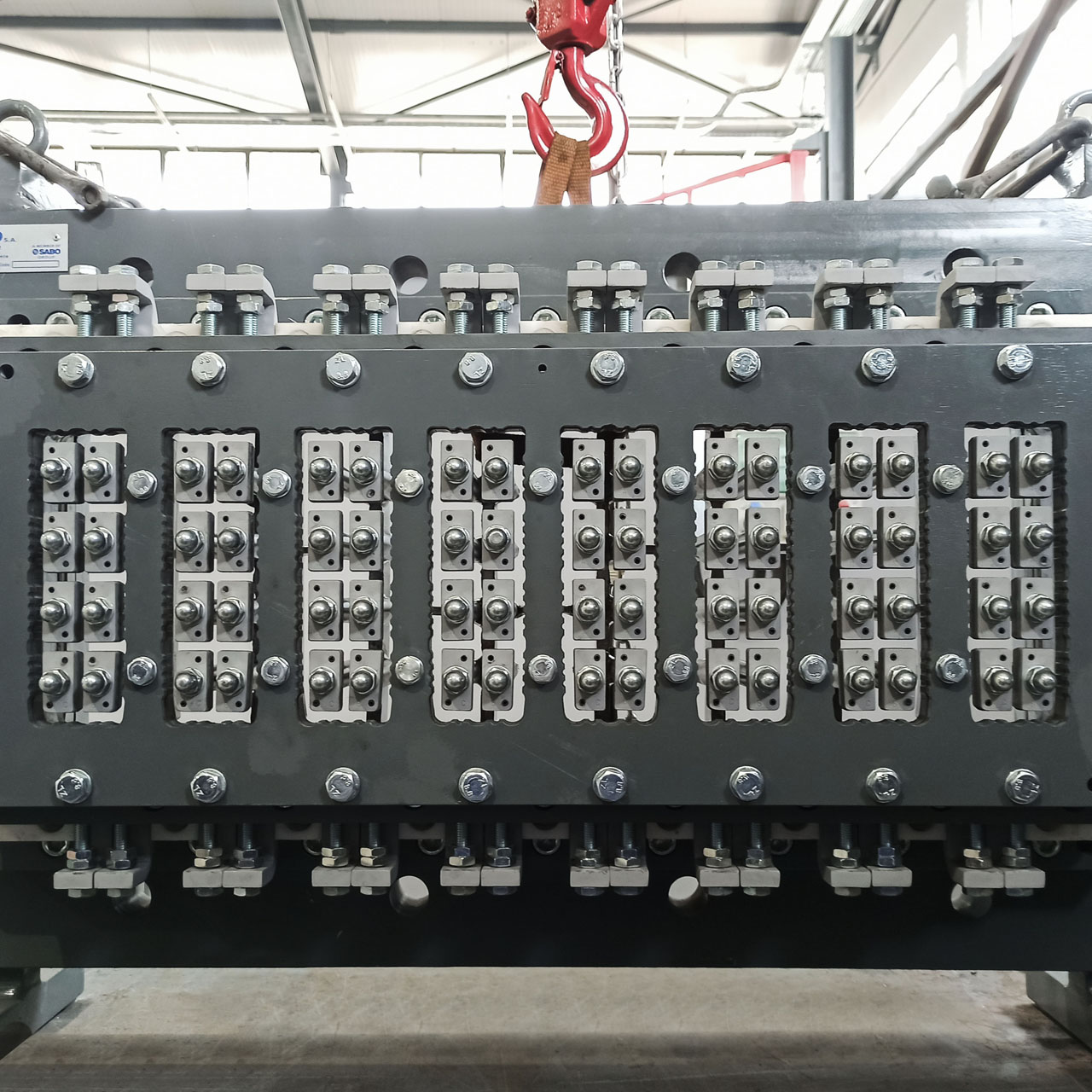

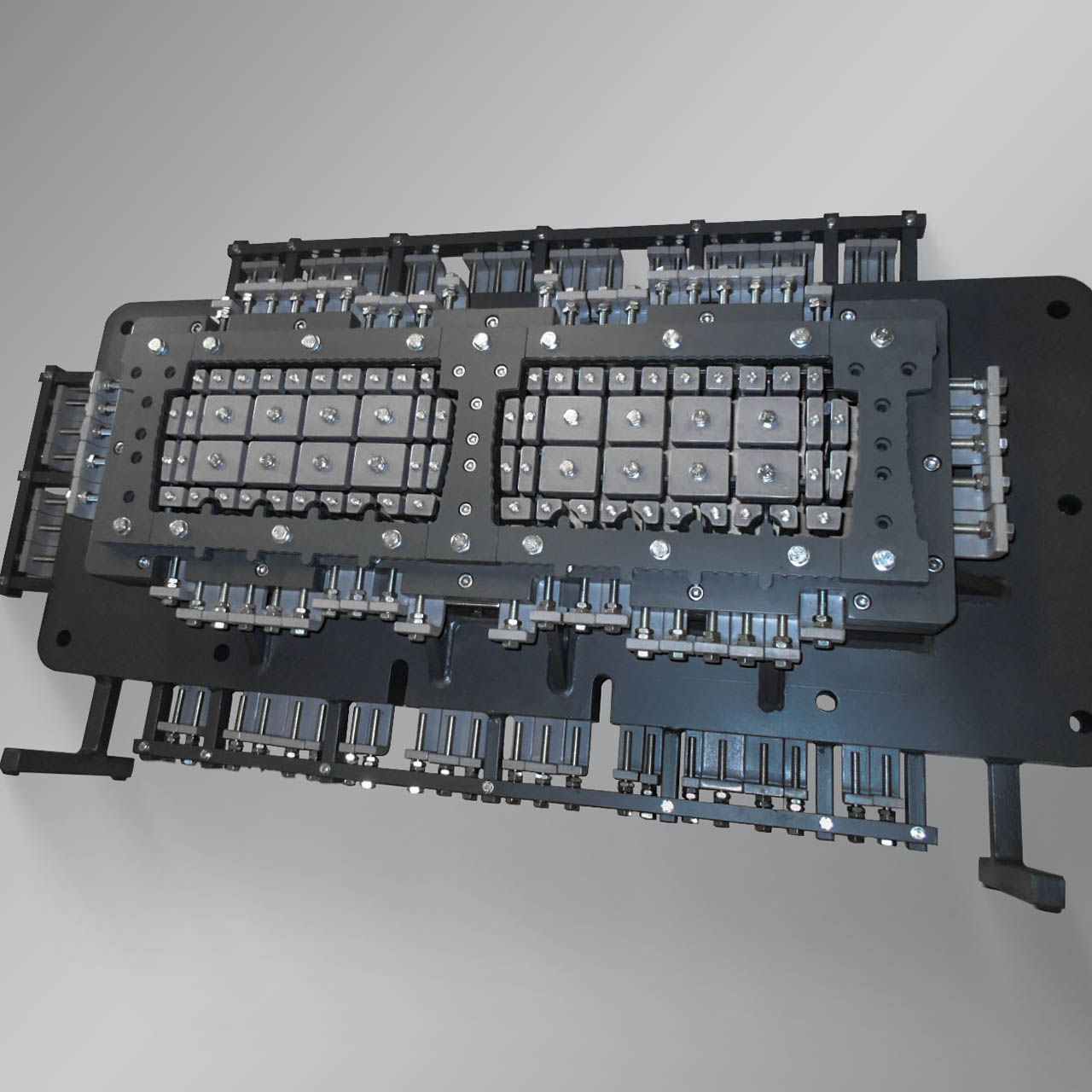

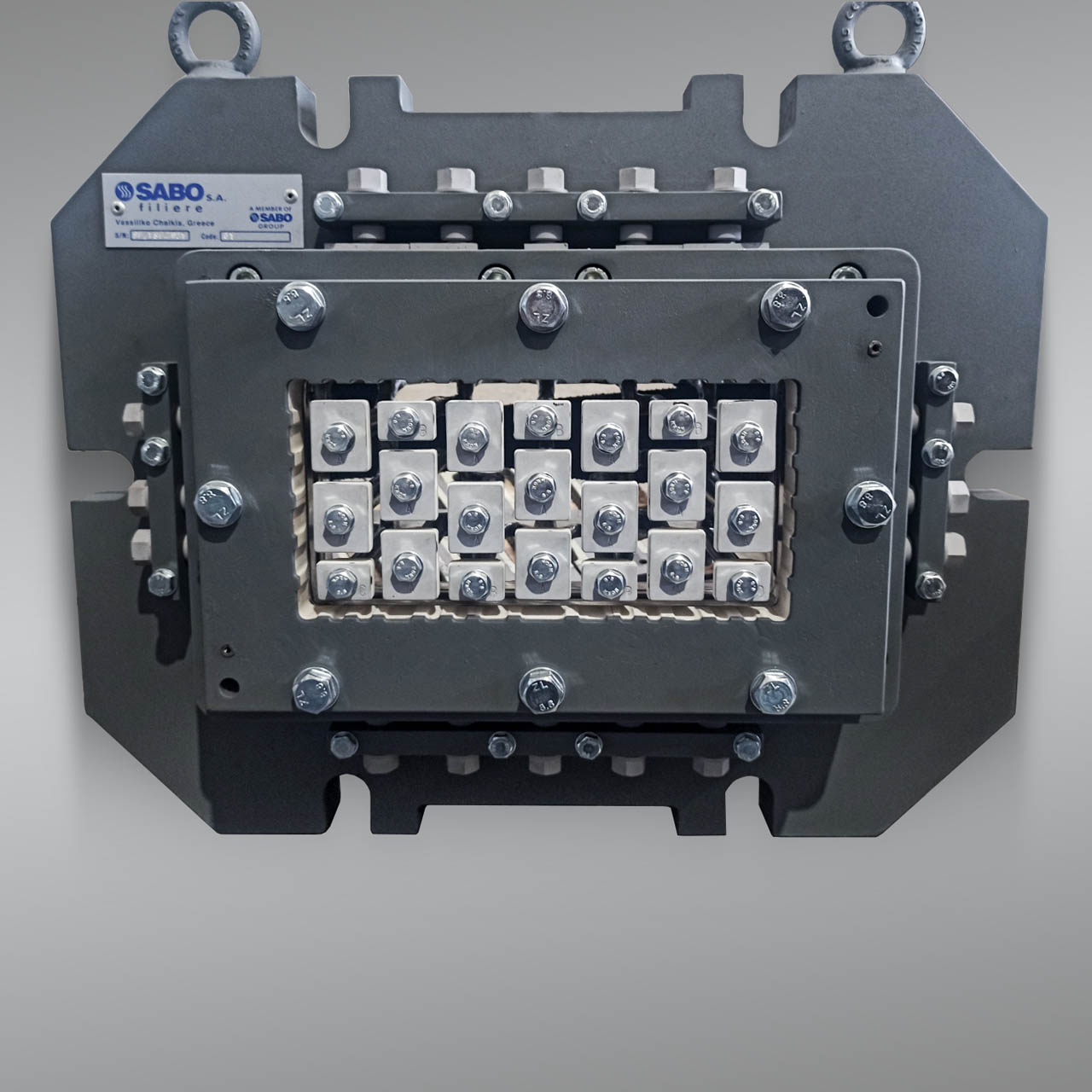

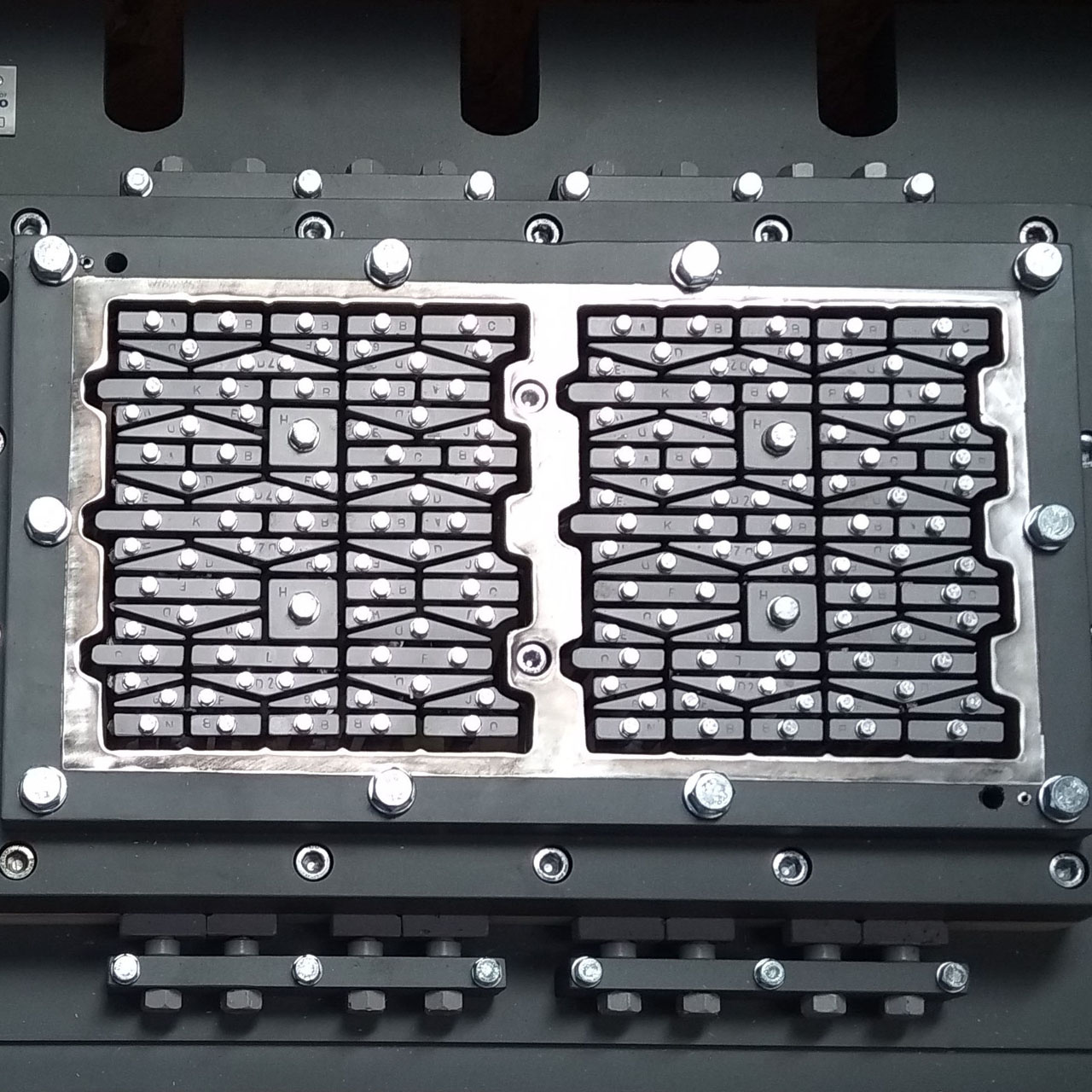

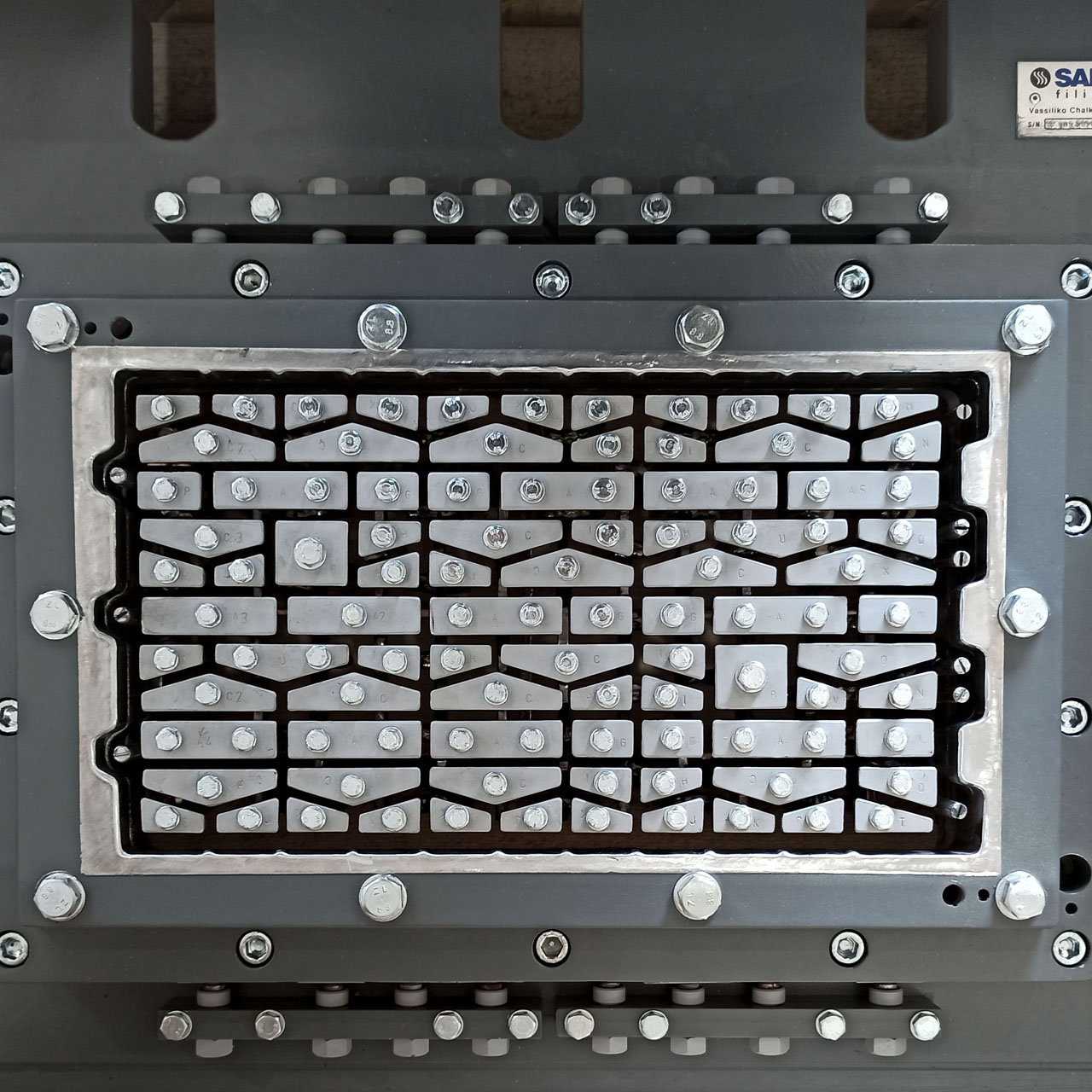

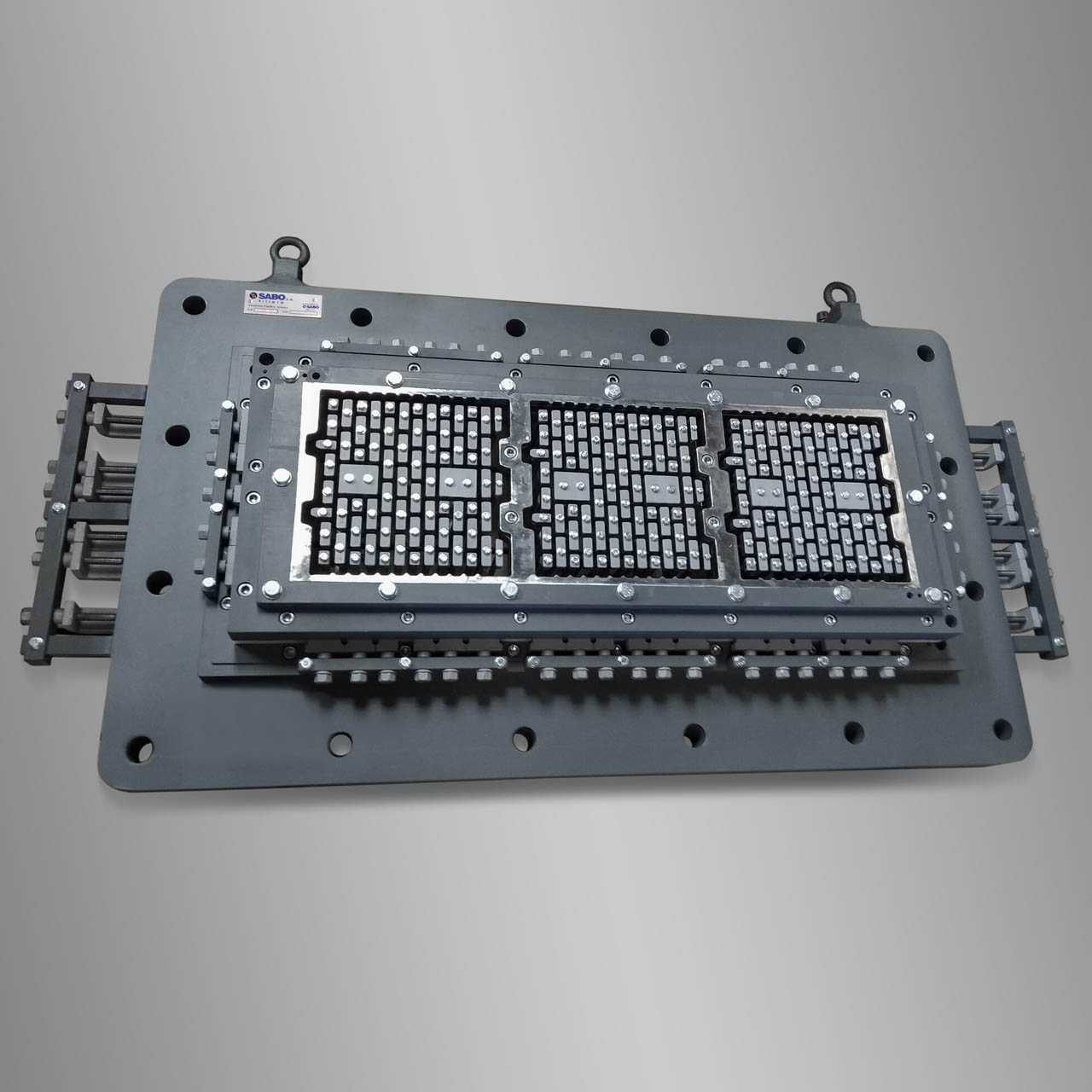

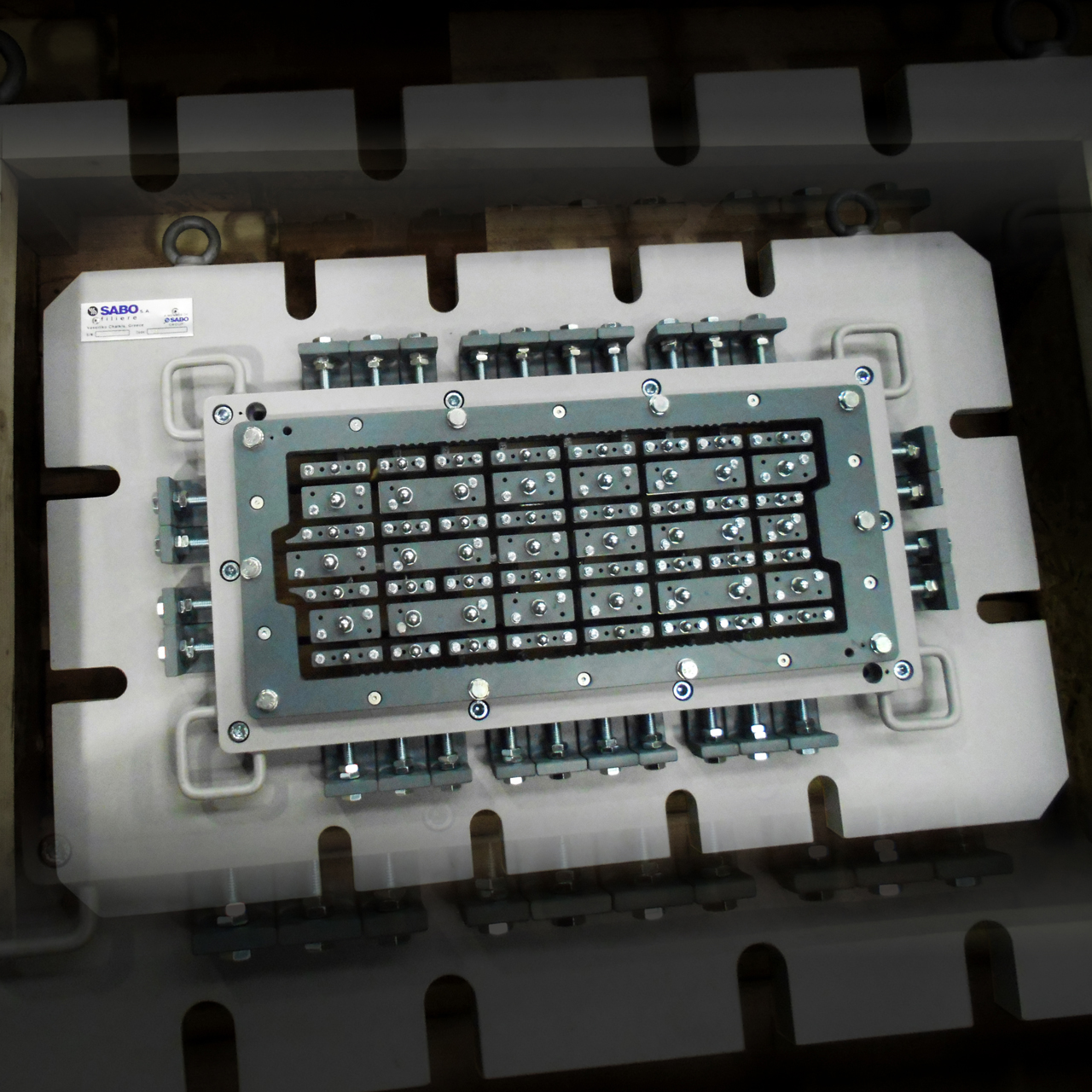

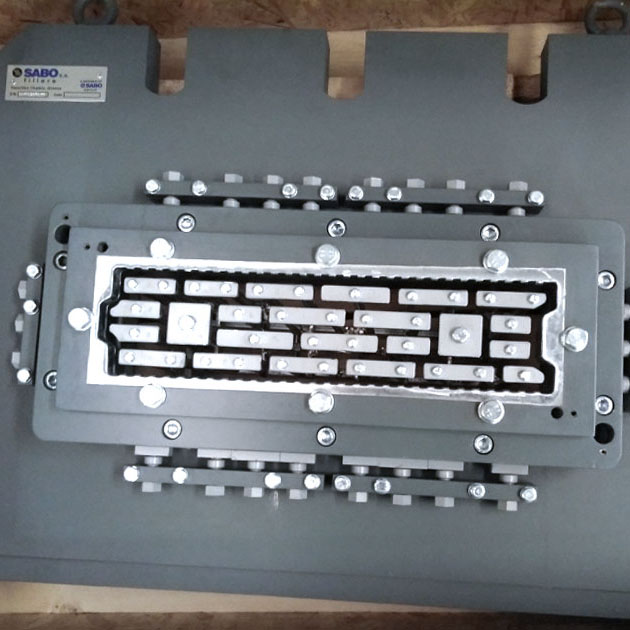

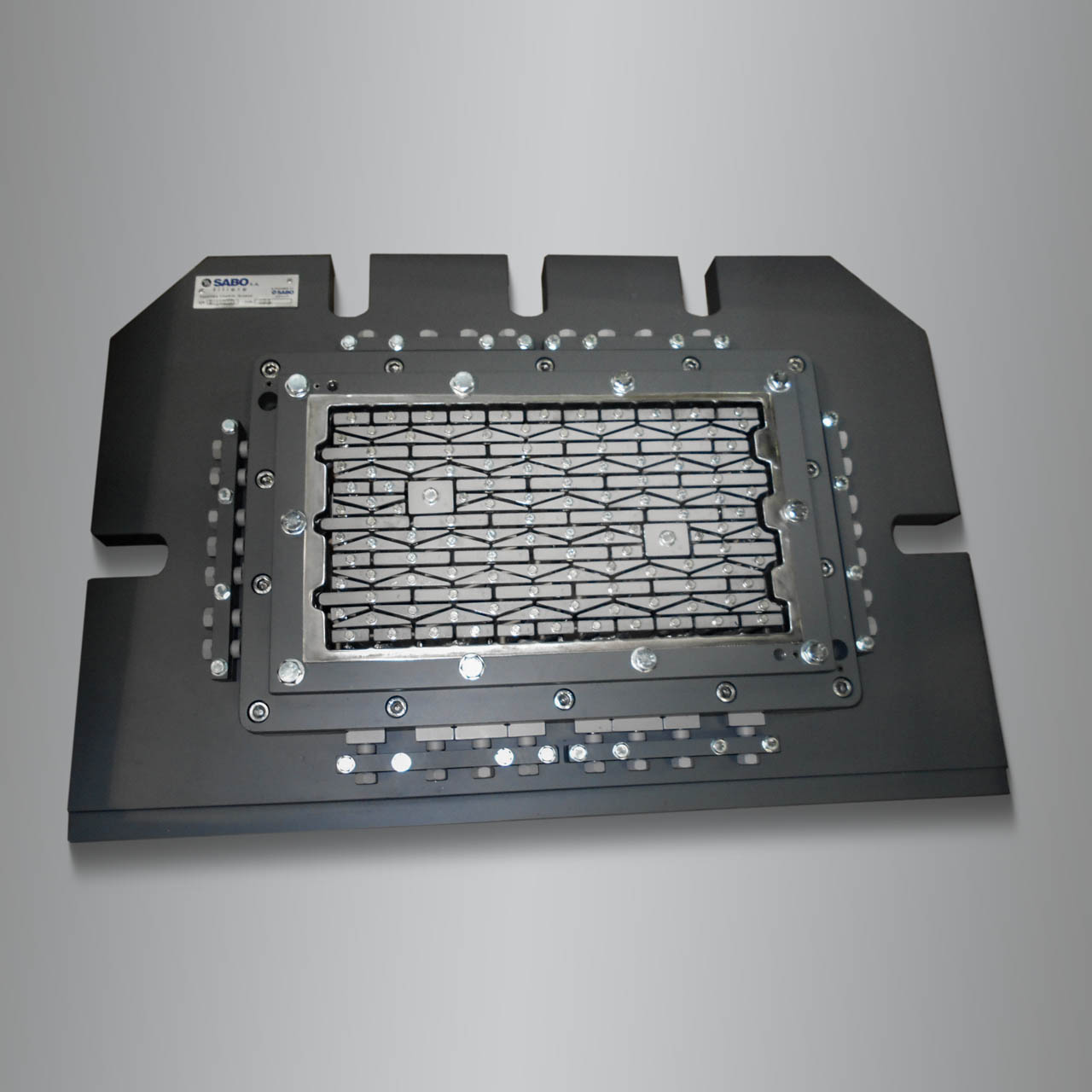

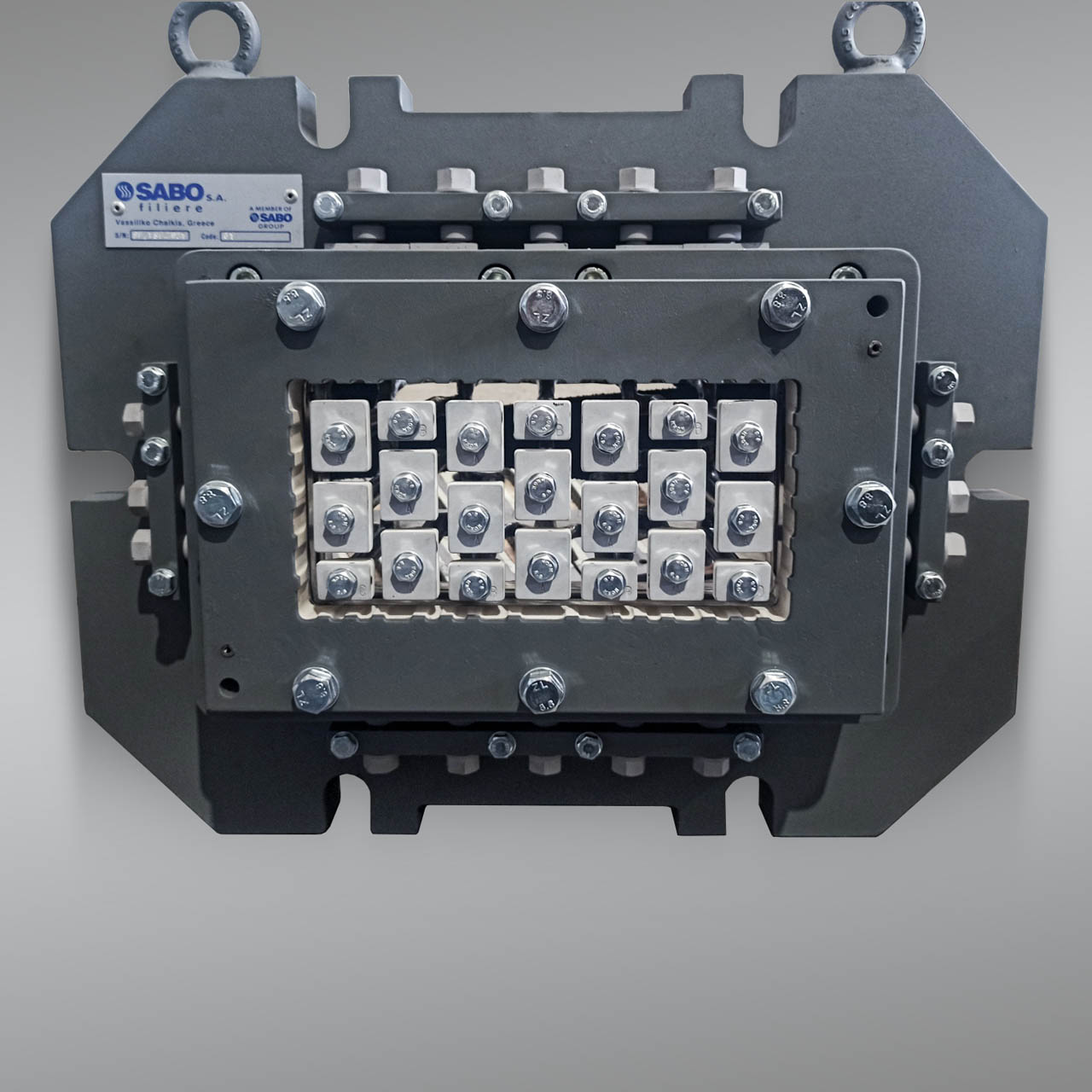

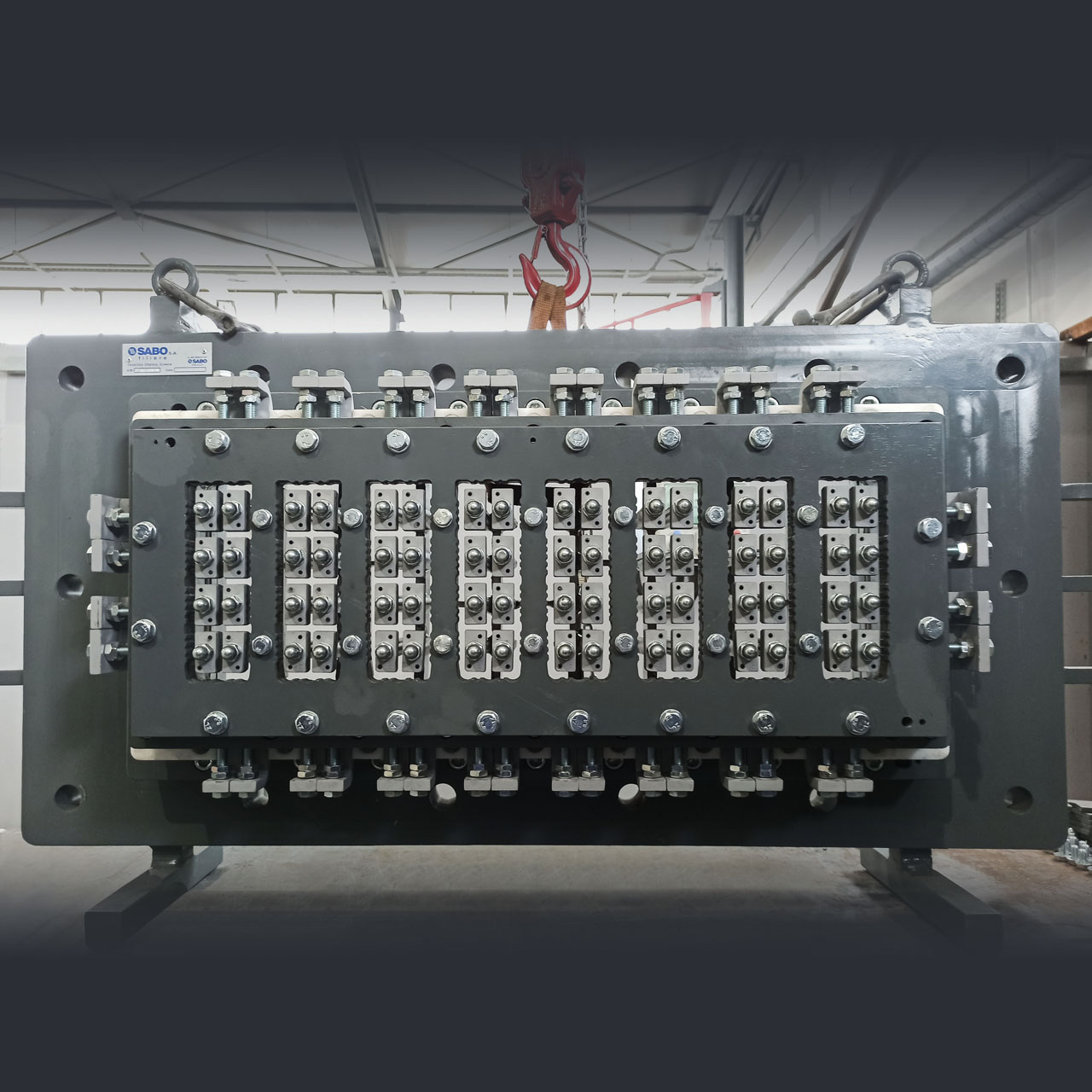

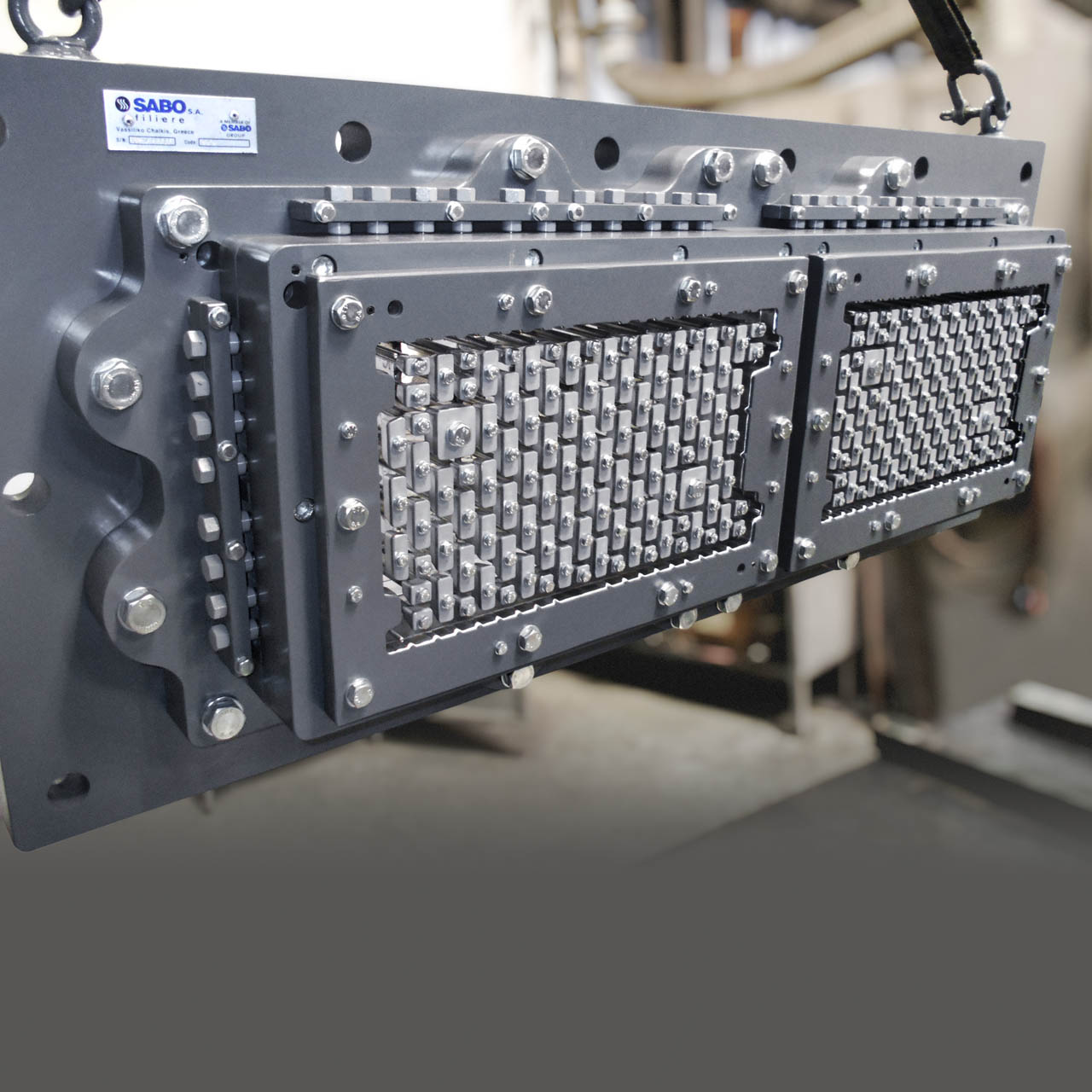

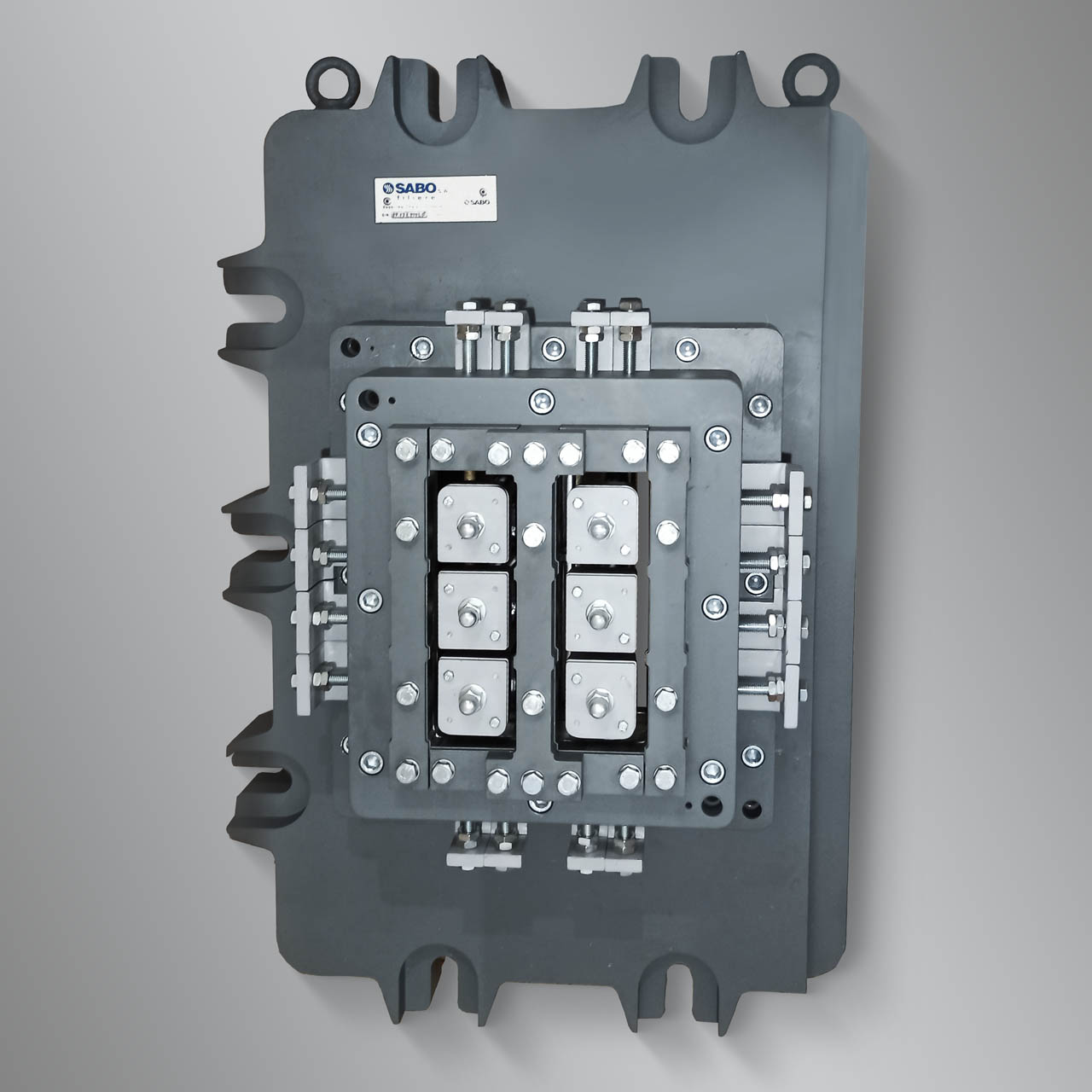

Hollow Bricks

Dies specifically designed for the production of hollow bricks, offering excellent extrusion stability and durability of the final product.

With flexible adjustment options via front and rear external brakes, they ensure uniform extrusion even in multi-output dies.

Key Features:

- Die conical part adapted to soil and extrusion process for optimal product quality

- Easy adjustment through internal & external brakes

- High extrusion stability with consistent output speed

- All parts are easily replaceable

Technical Specifications:

- Metal body of the die with hard plates and inner protective cones for easy maintenance

- Internal metal liners of hardened steels

- Core holder made by hardened steel or hard chromium plated steel.

- Cores made by heat treated steel, chromium plated steel, ceramic materials, or tungsten carbide.

- Frame by heat treated steel, chromium plated steel, ceramic materials, or tungsten carbide.

Compatible Die Types:

SFS, SFI-B1, SFM-B1, SFM-B2

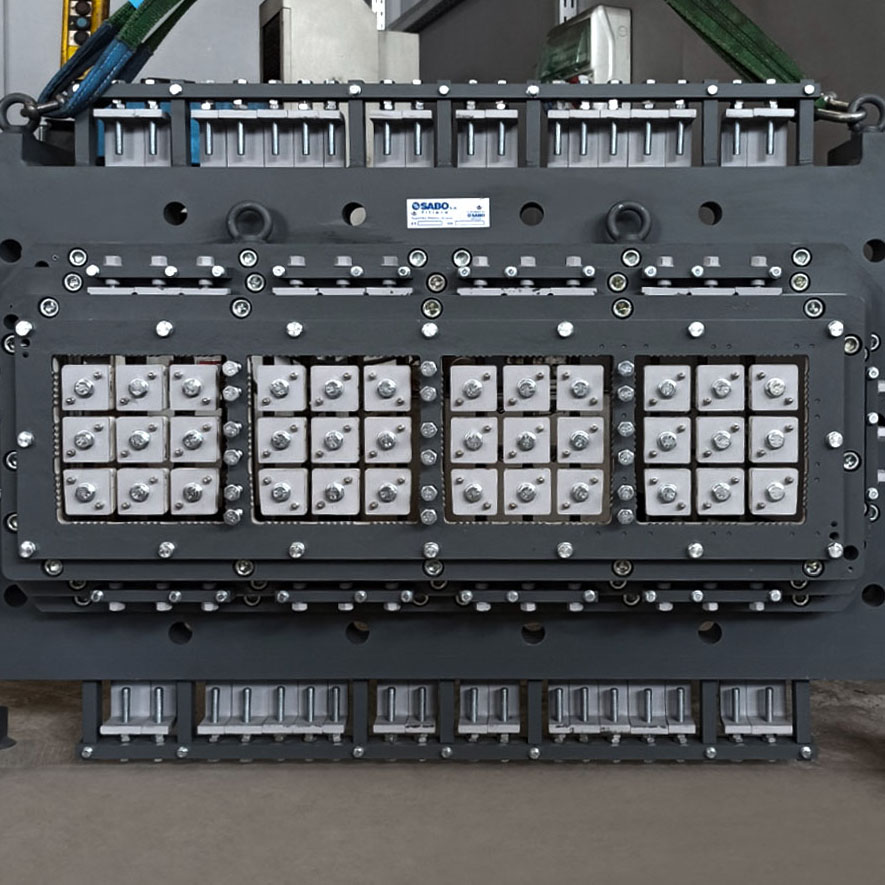

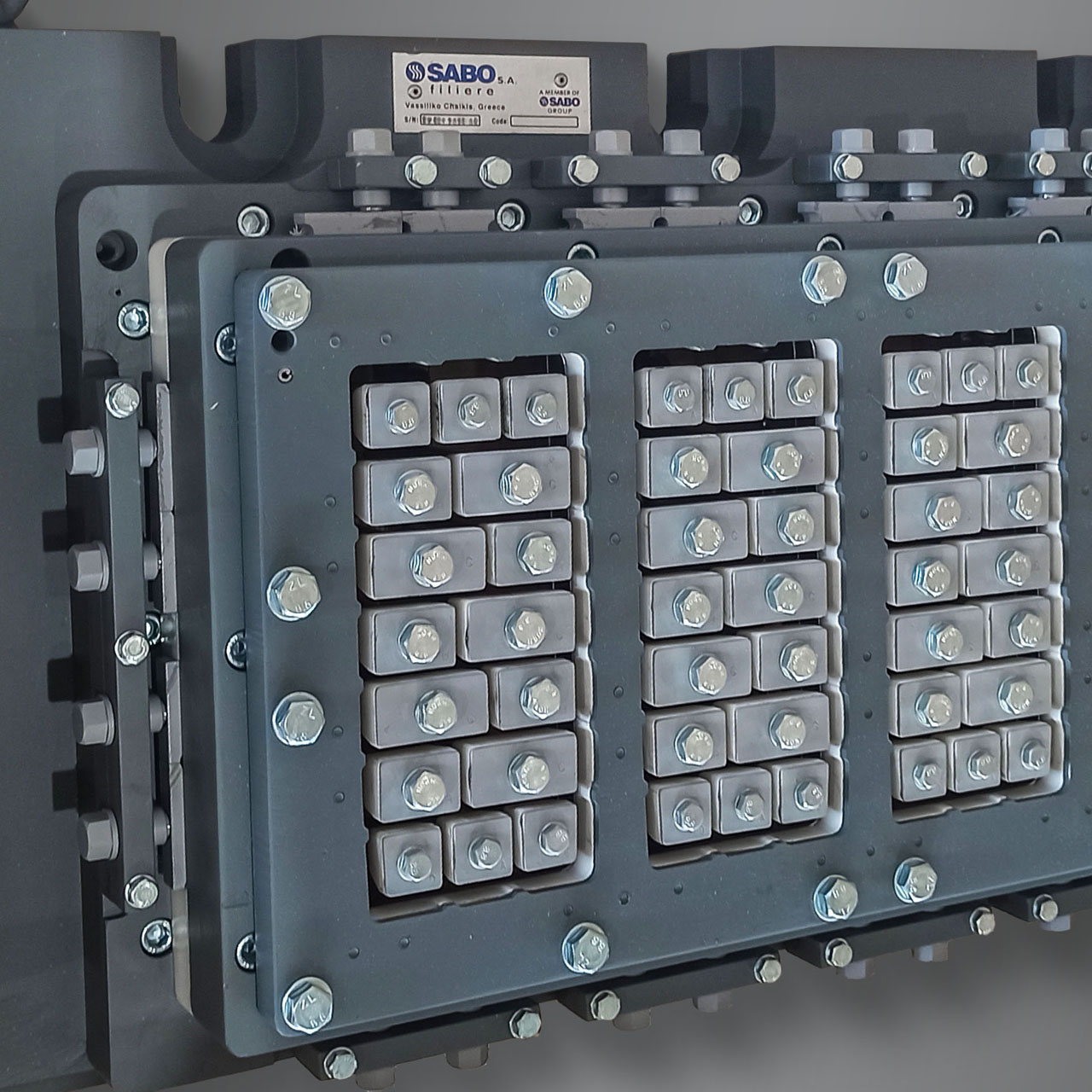

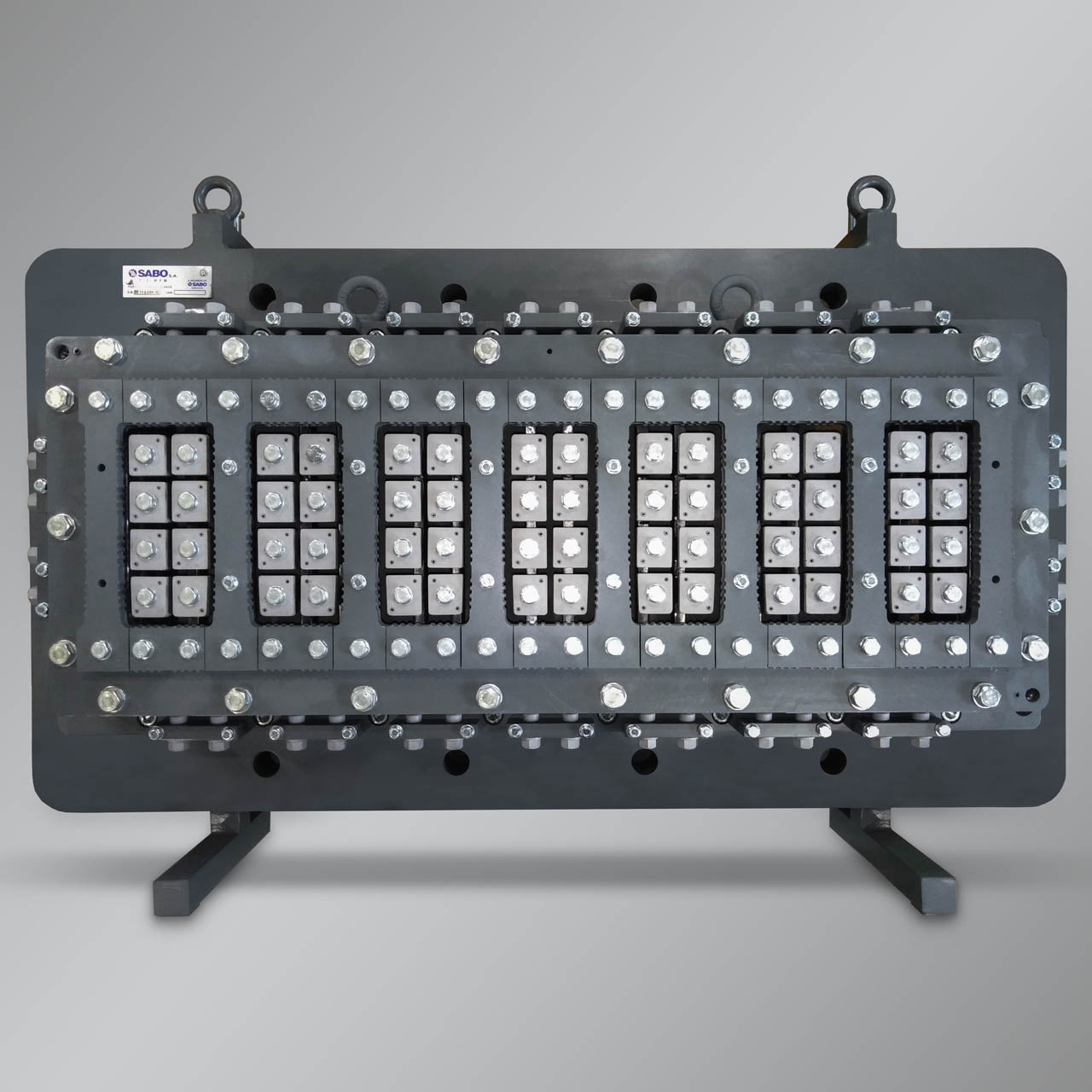

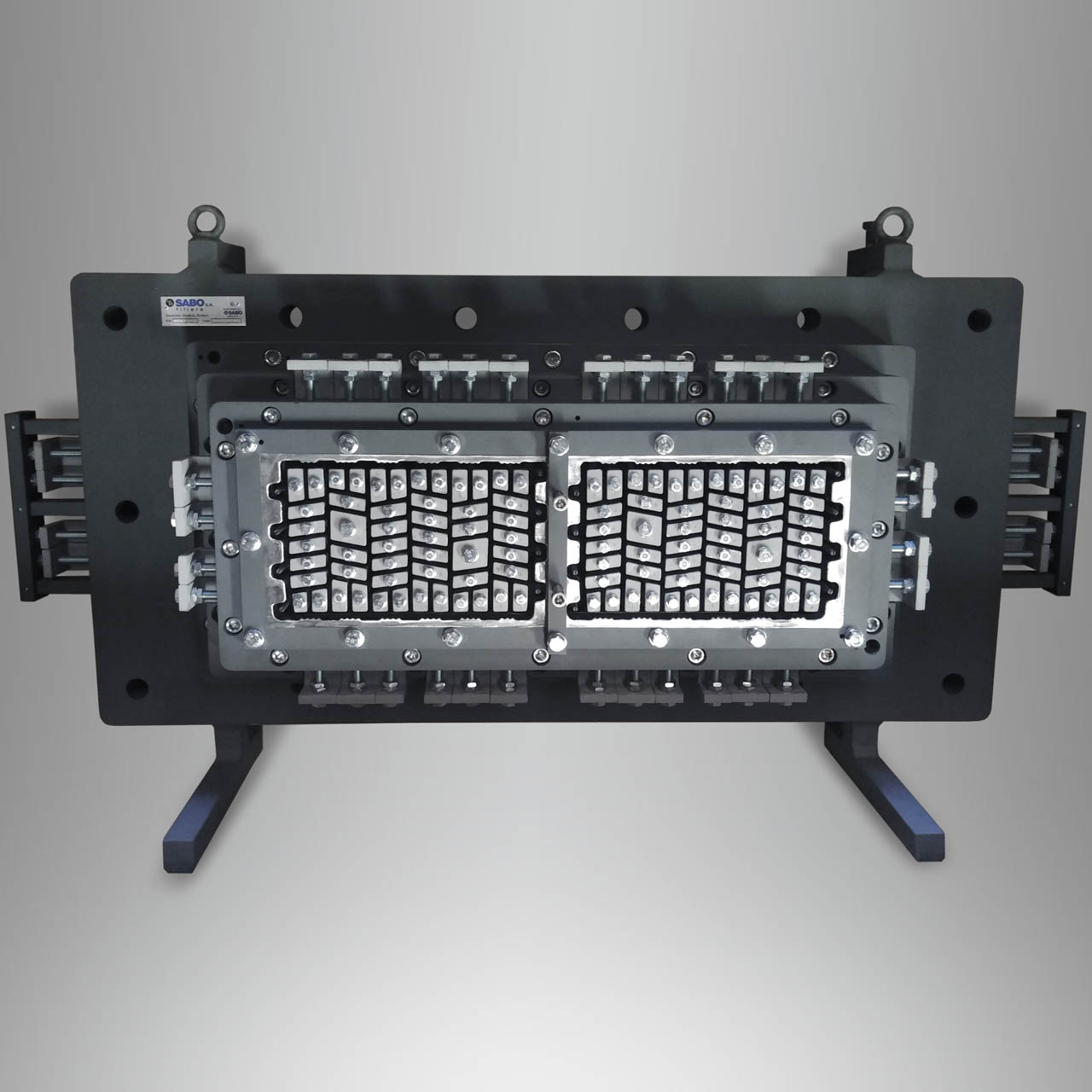

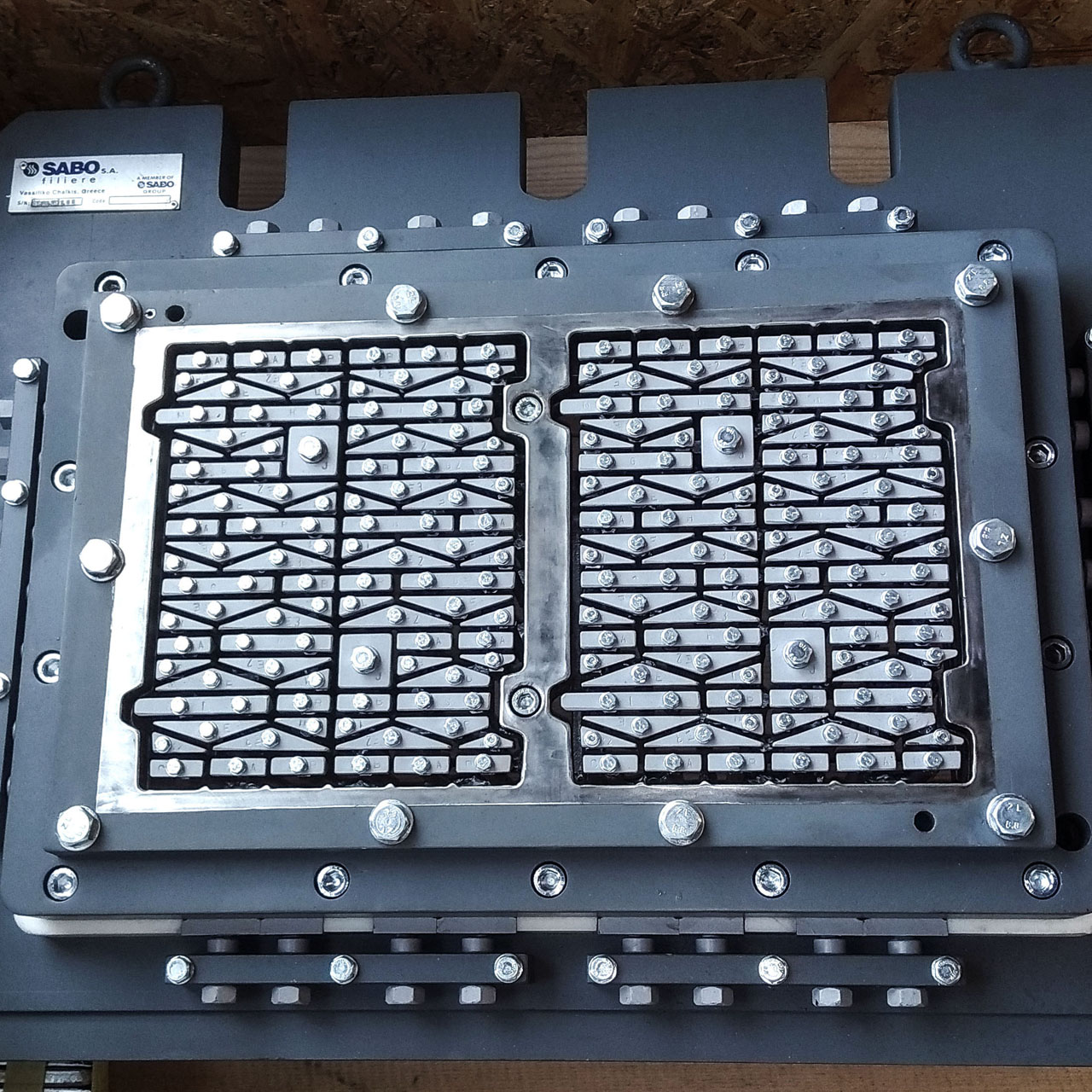

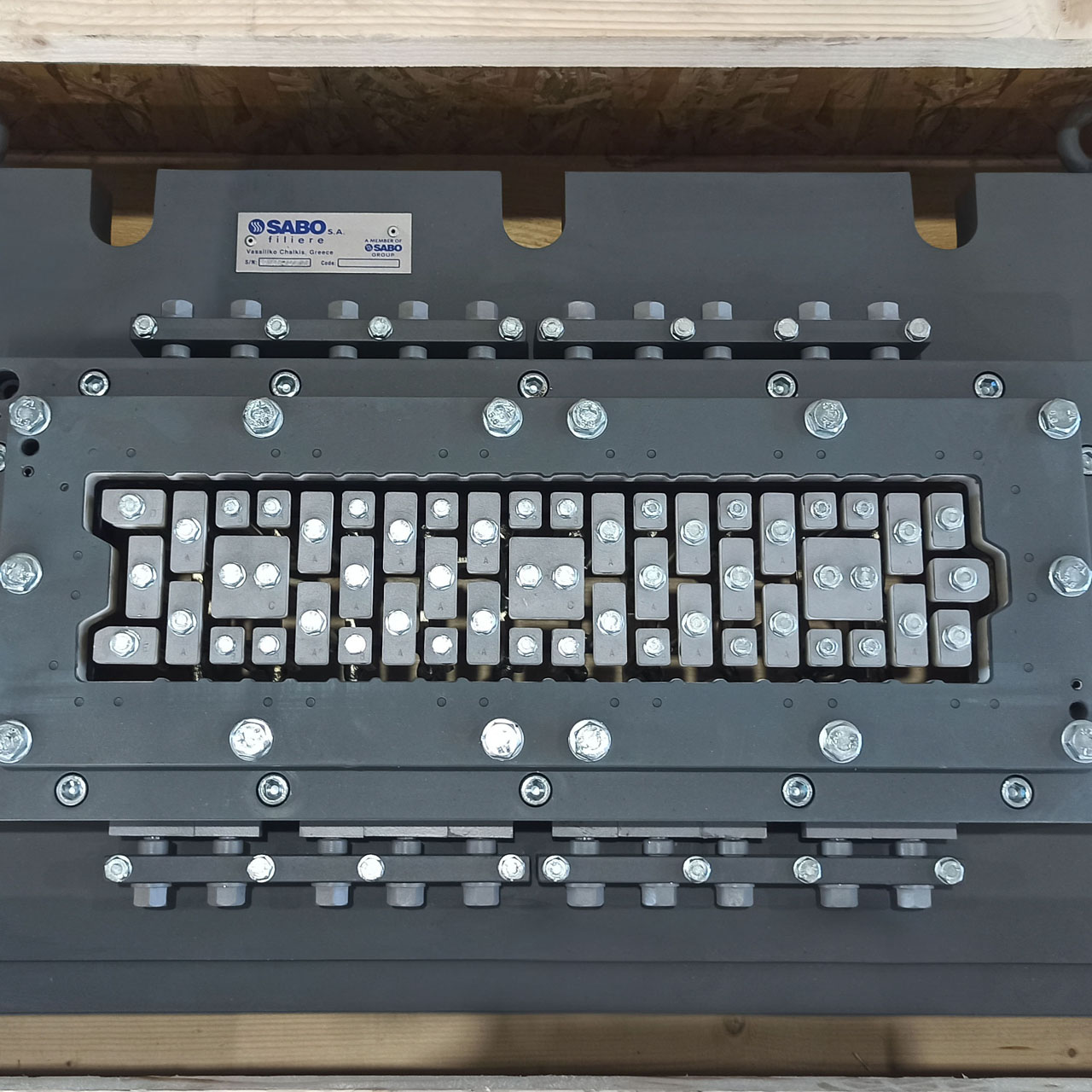

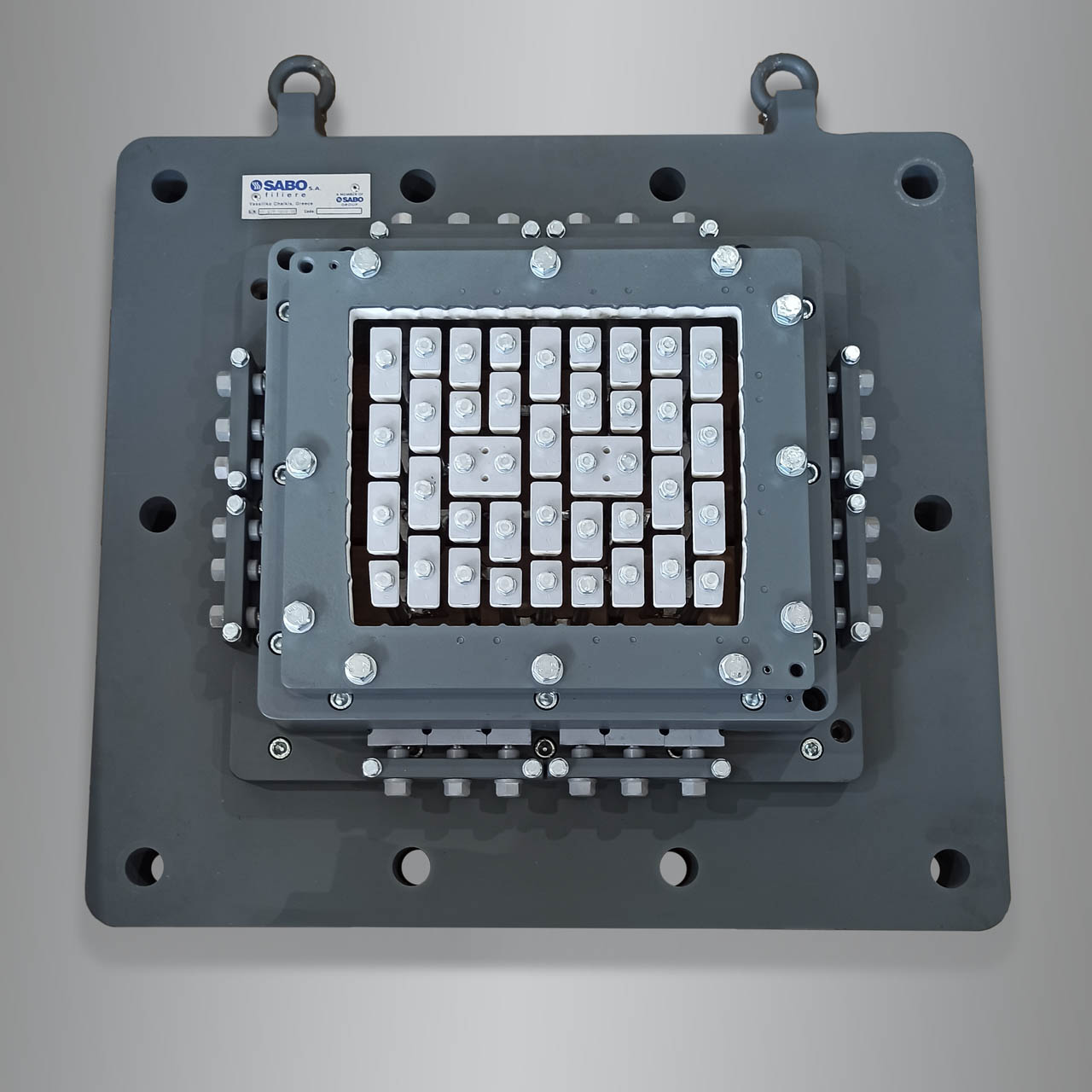

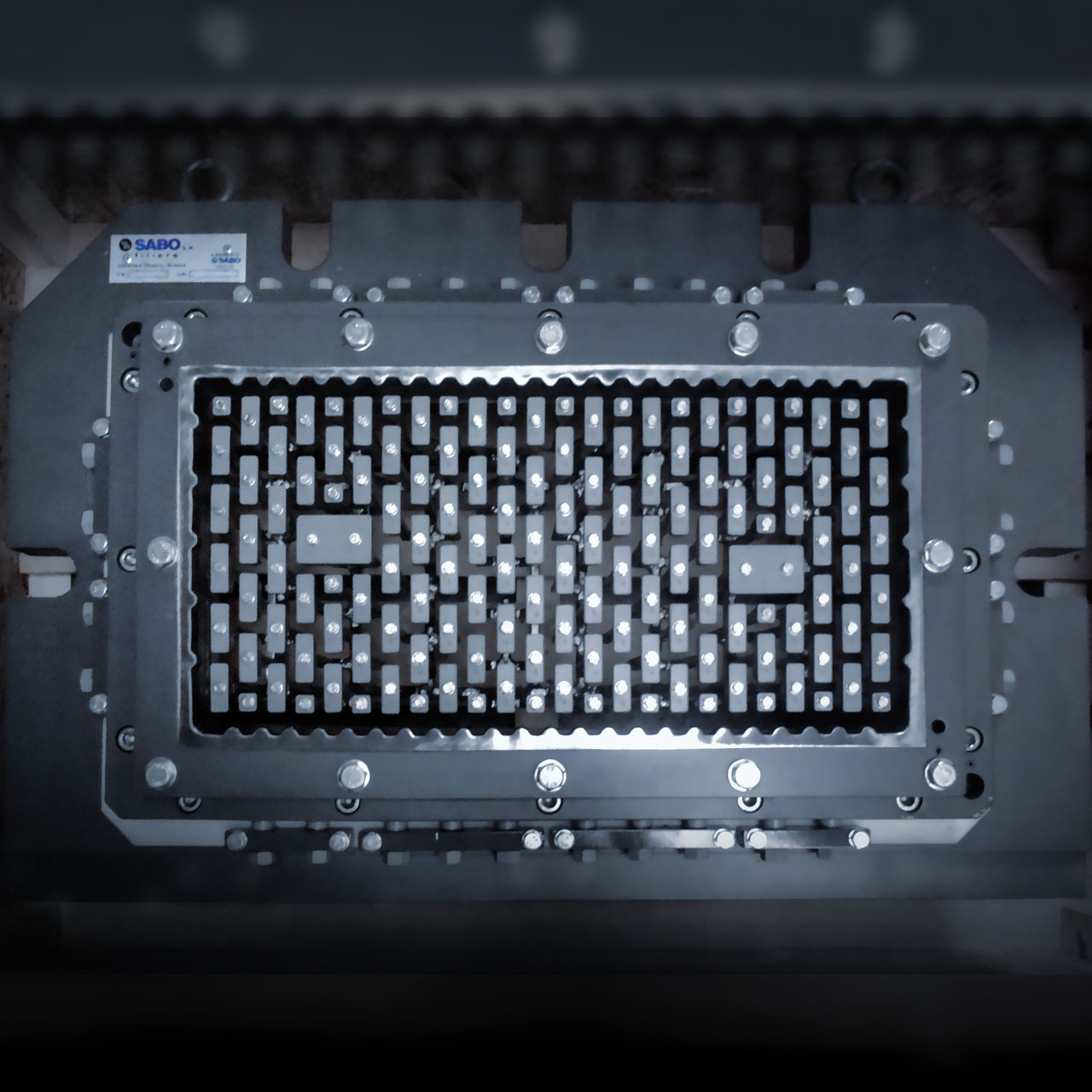

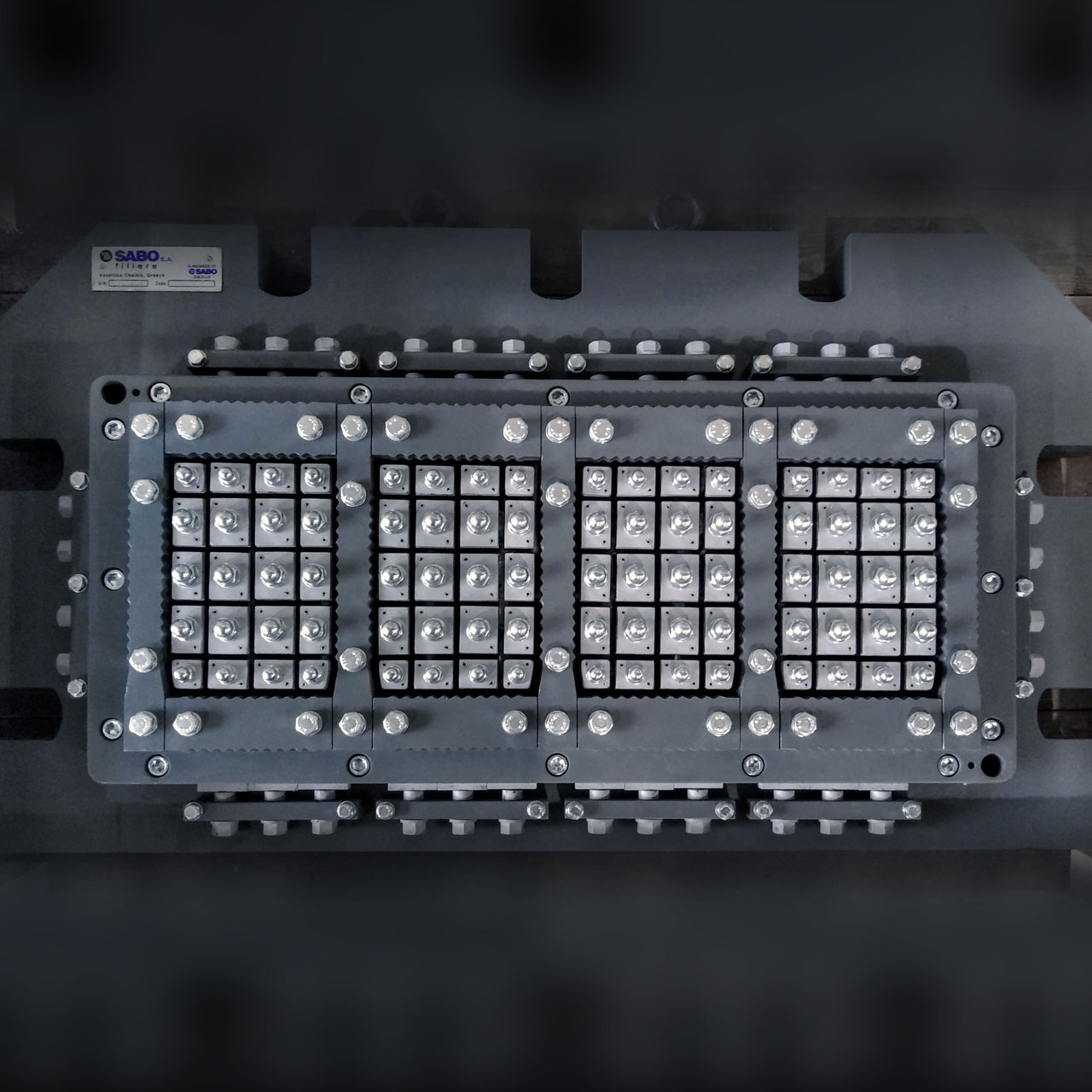

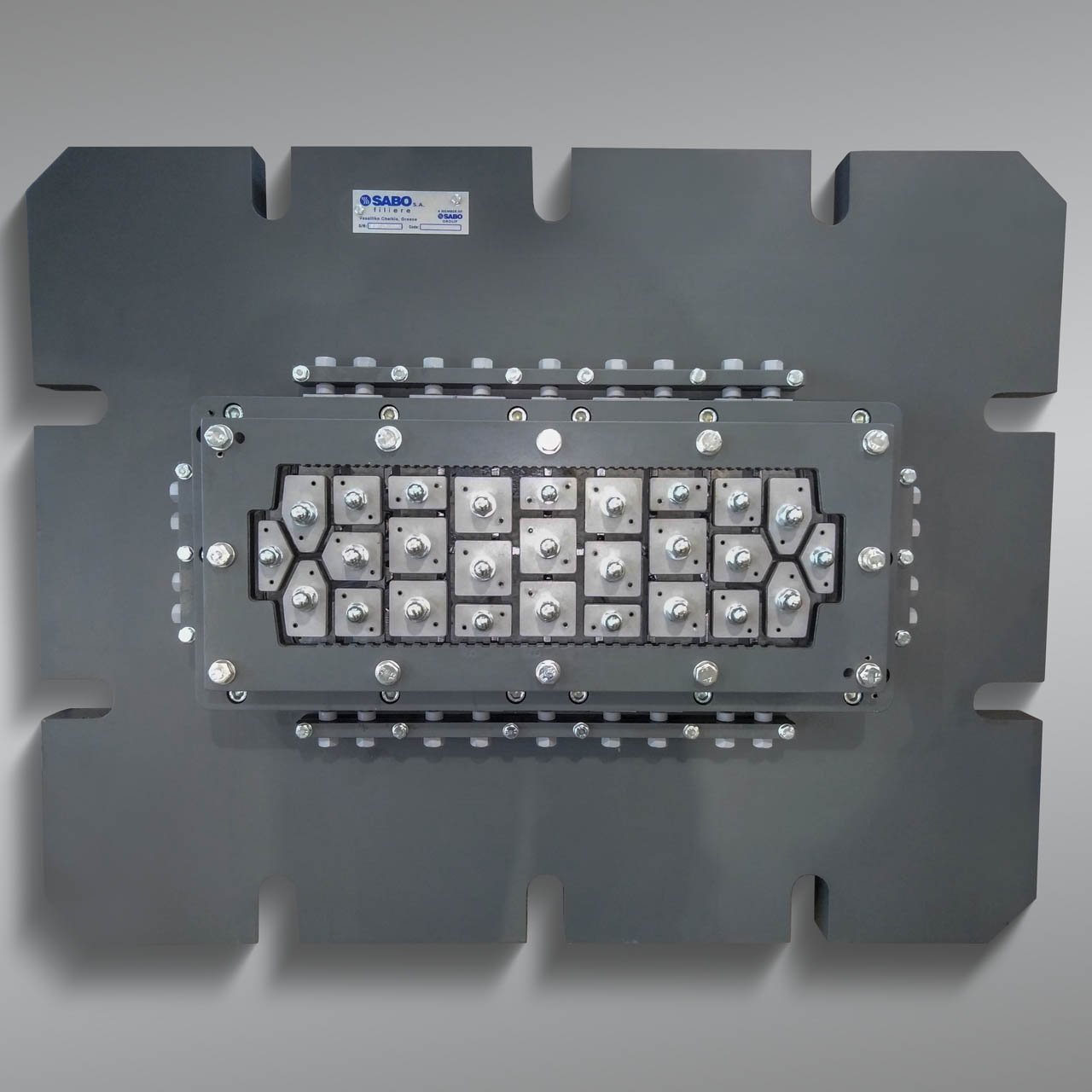

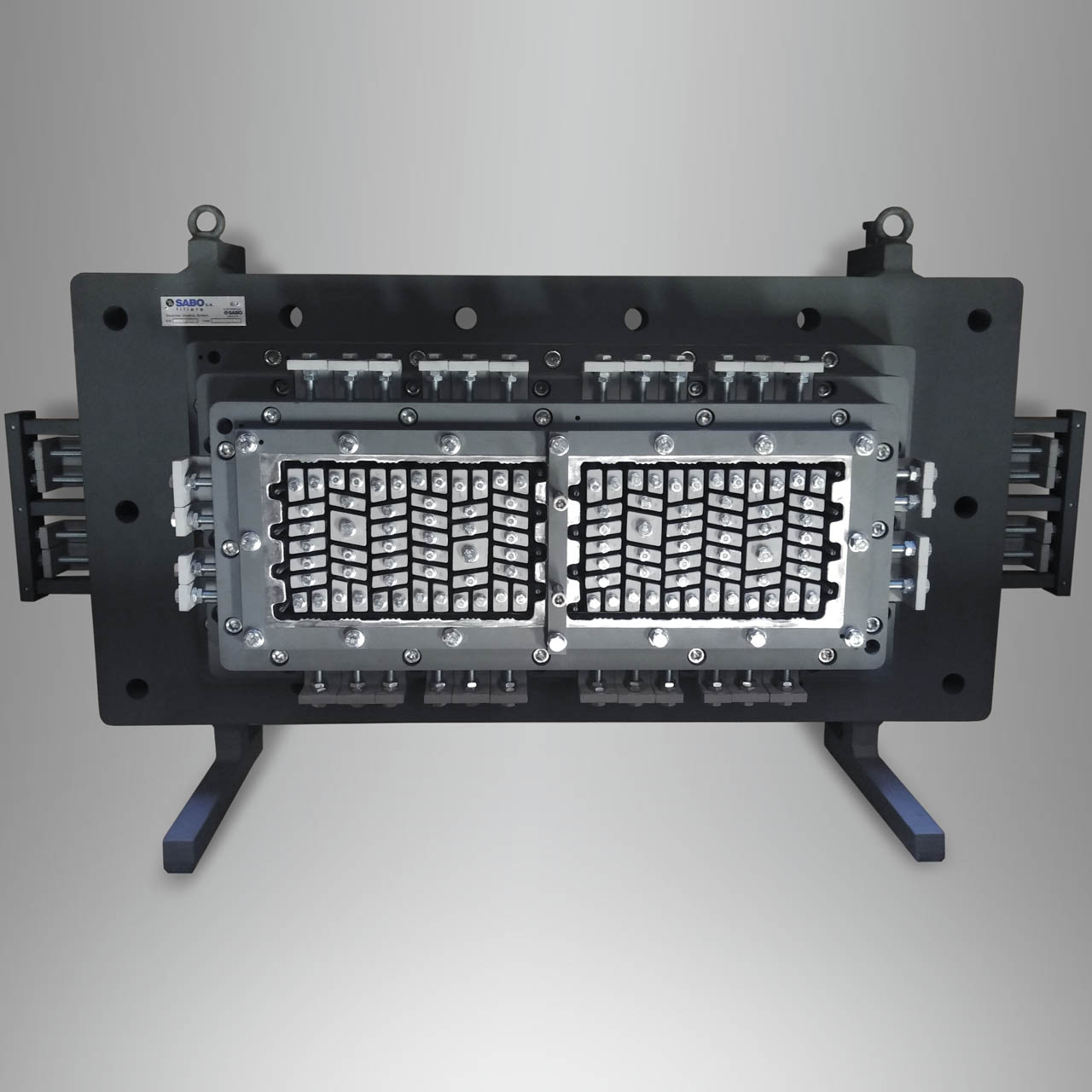

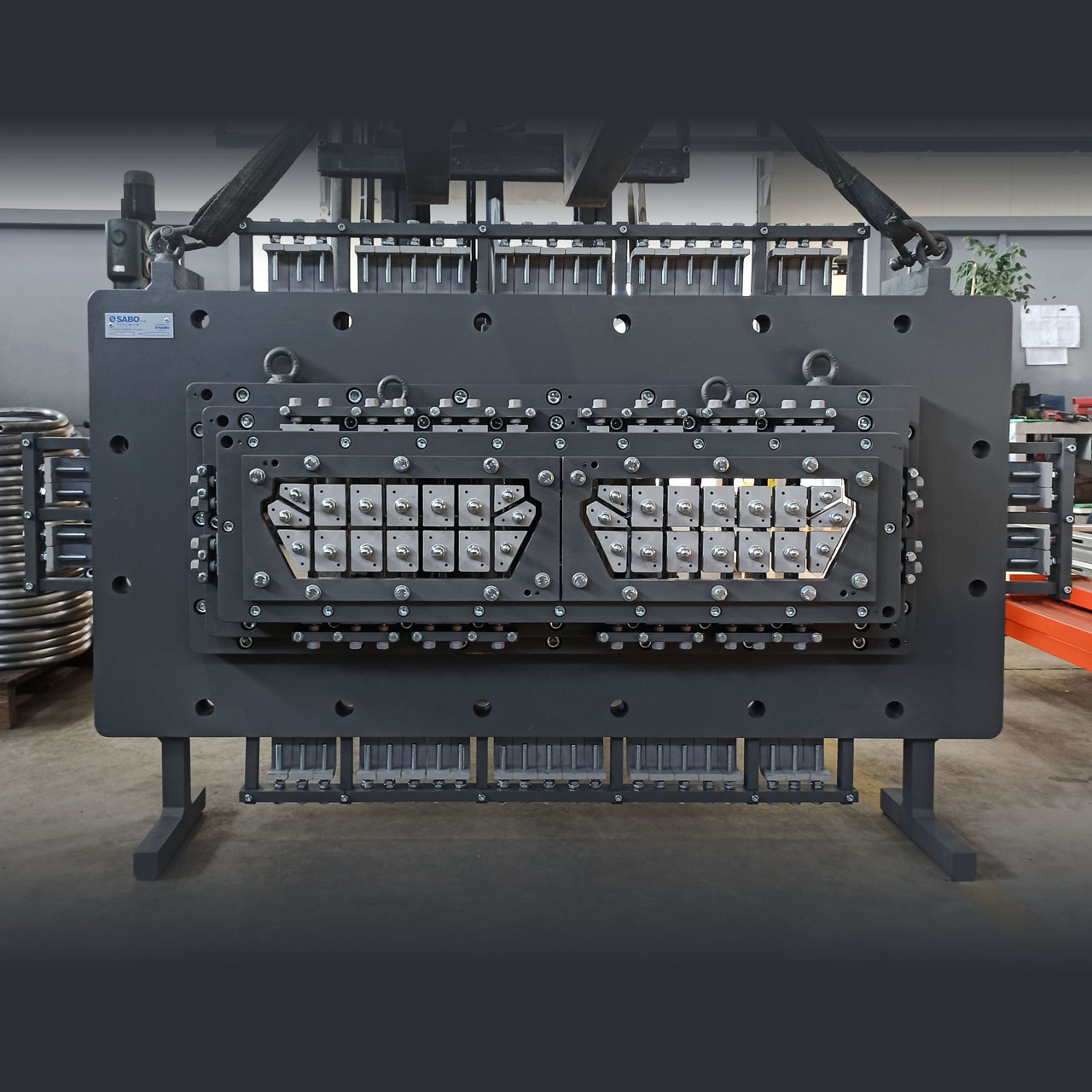

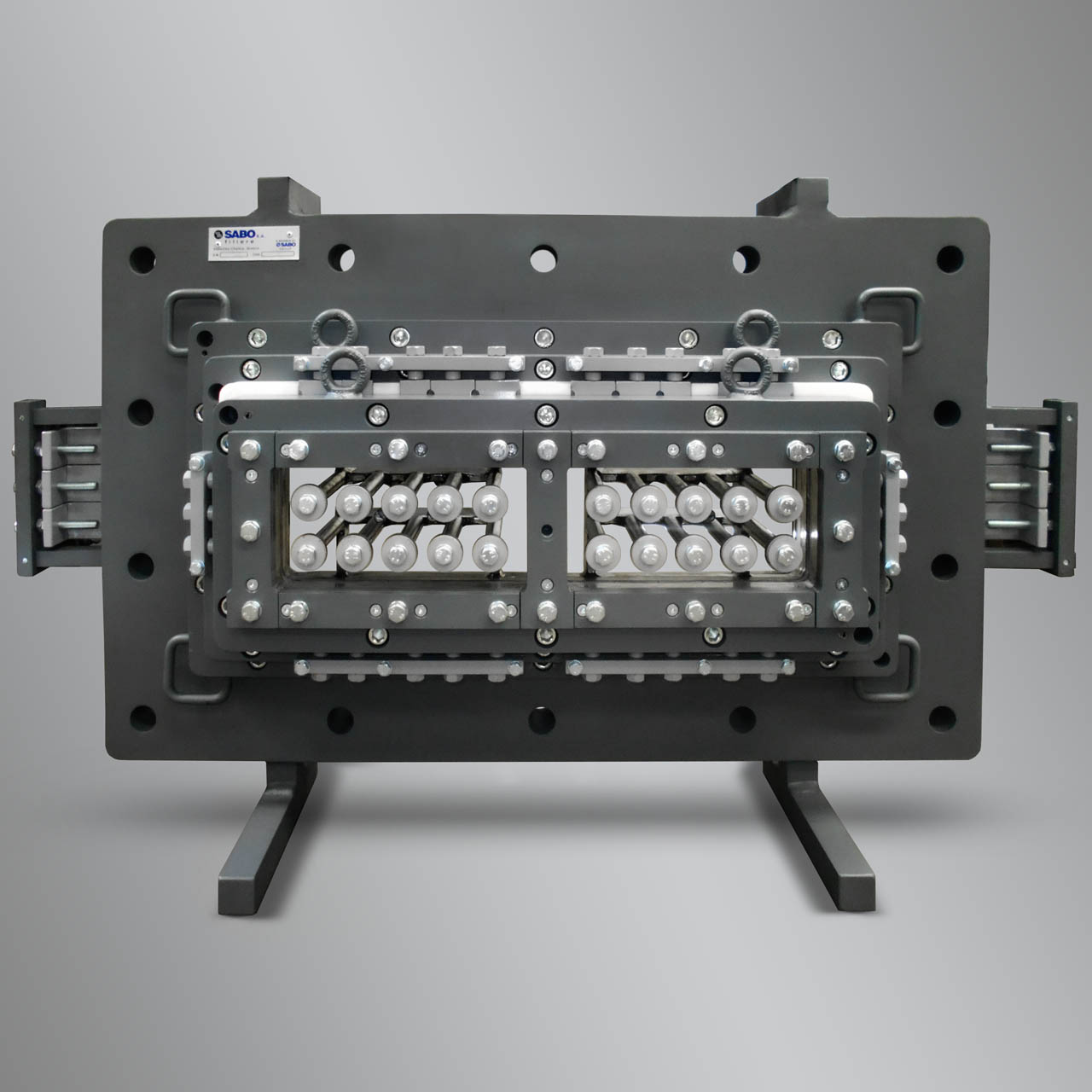

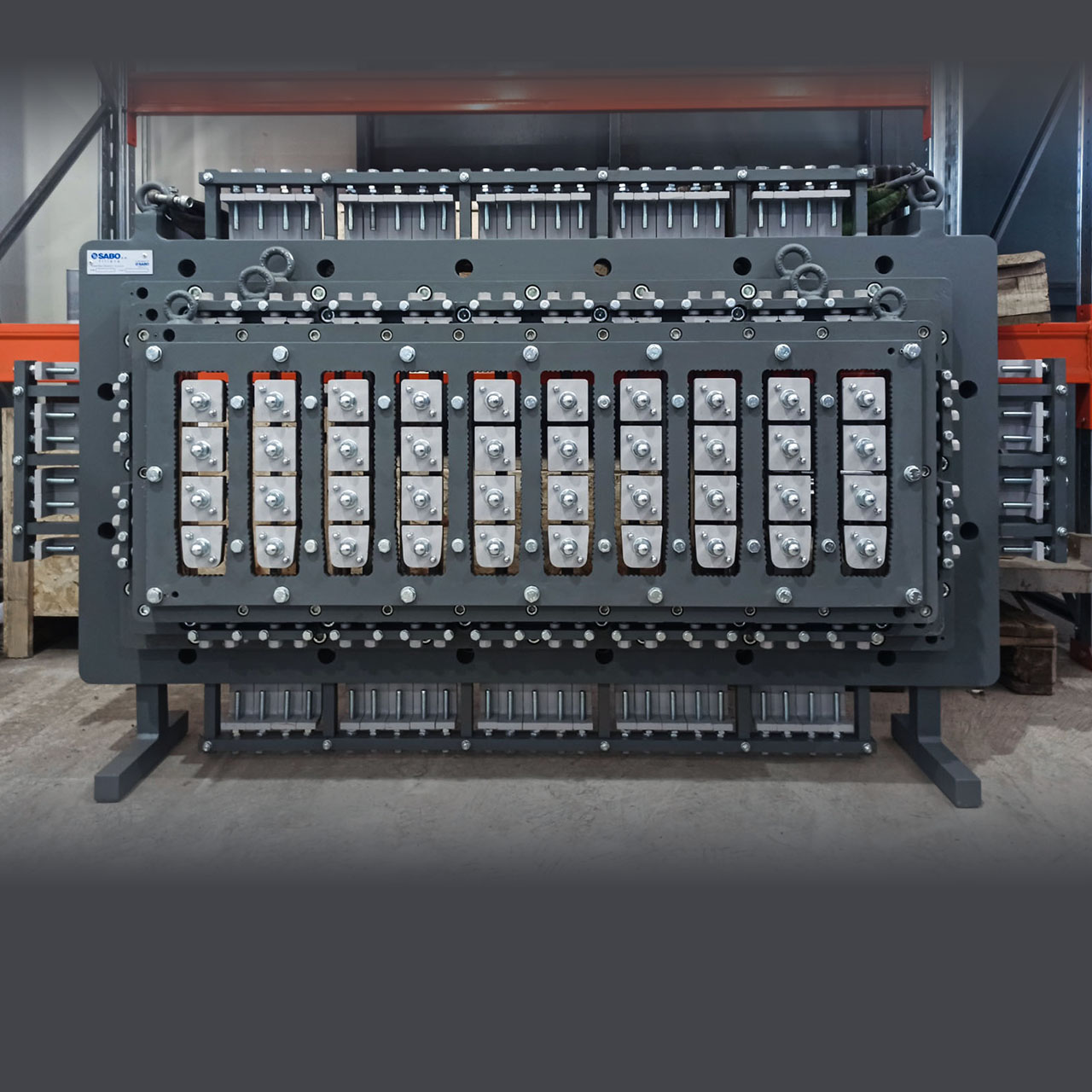

Thermal Insulated Blocks

Dies for the production of big clay bricks and blocks designed to ensure balanced extrusion without internal stresses.

The optimized geometry guarantees strength and dimensional precision, with flexible adjustment options tailored to each client via internal or external brakes.

Key Features:

- Mid-length conical core customized to the soil and extrusion properties

- Easy brake adjustment (internal/external)

- Optimized bridge holding system for perfect balance

- Fully replaceable components

Technical Specifications:

- Metal body with durable plates and protective internal cones

- Cones made of hardened or chrome-plated steel

- Cores made of hardened or chrome-plated steel

- Cores made by heat treated steel, or chrome-plated steel, ceramics, or tungsten carbide

- Basins of matching composition

- Internal and external brakes with tungsten carbide lining or hard chrome plating

Compatible Die Types:

SFS, SFI-B1, SFM-B1, SFM-B2

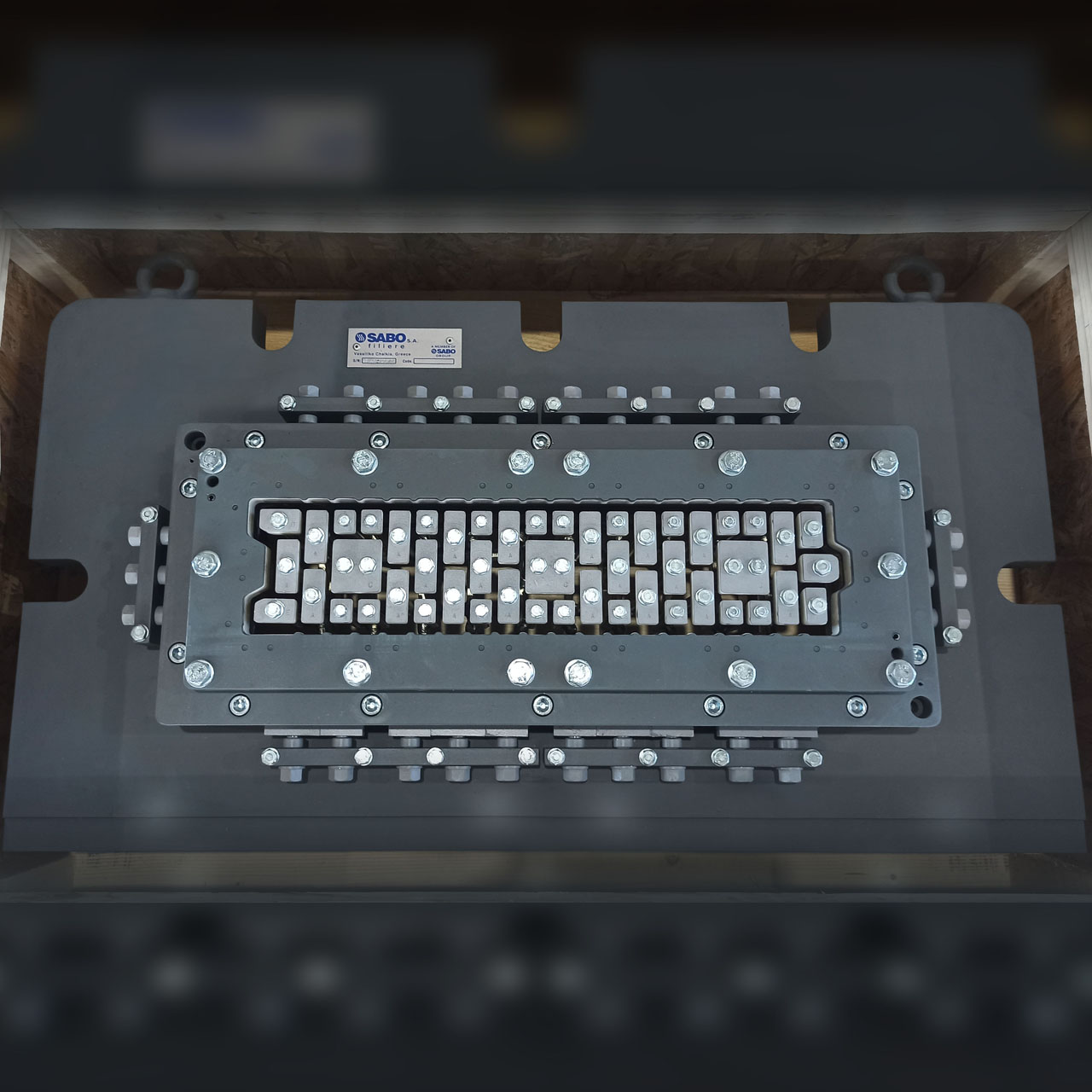

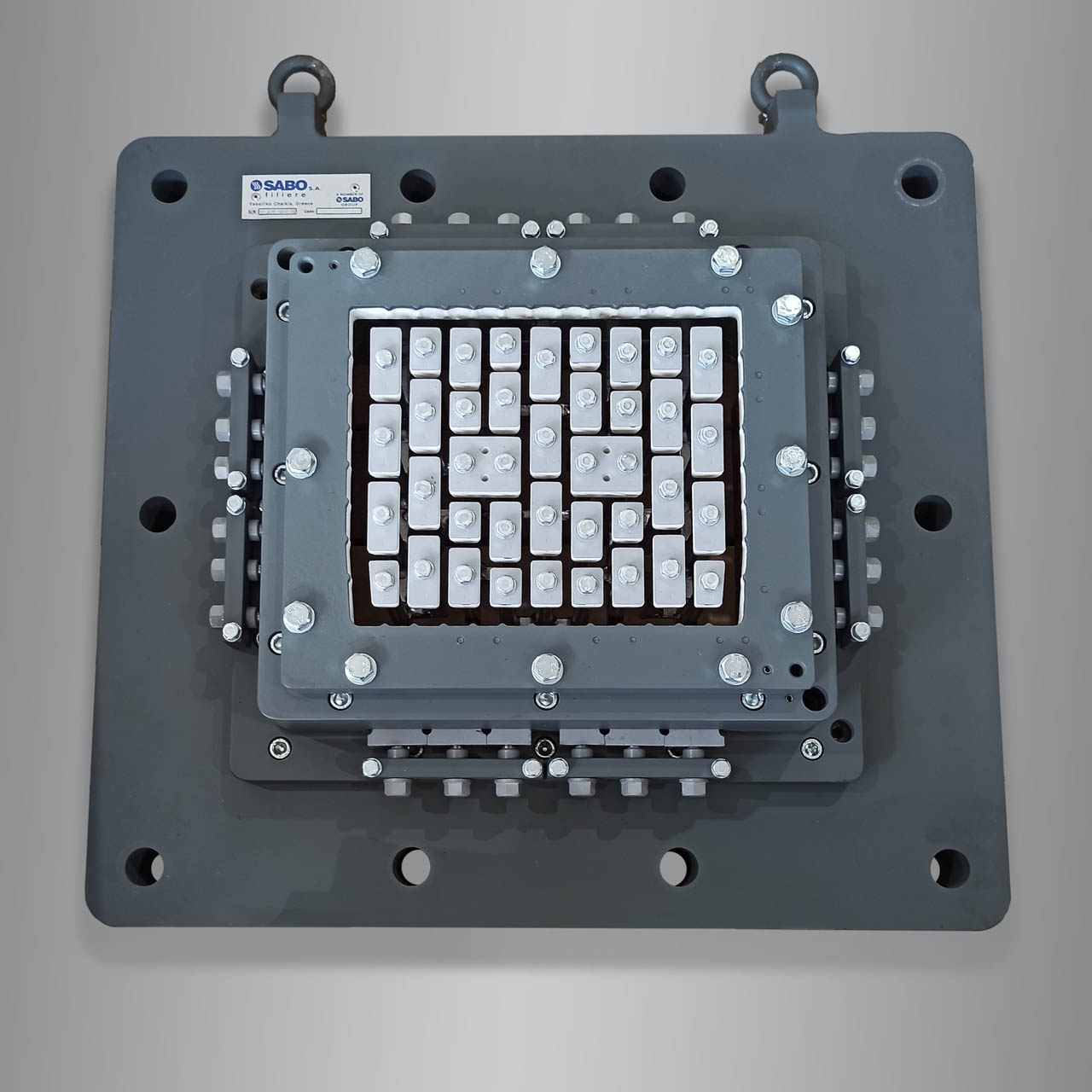

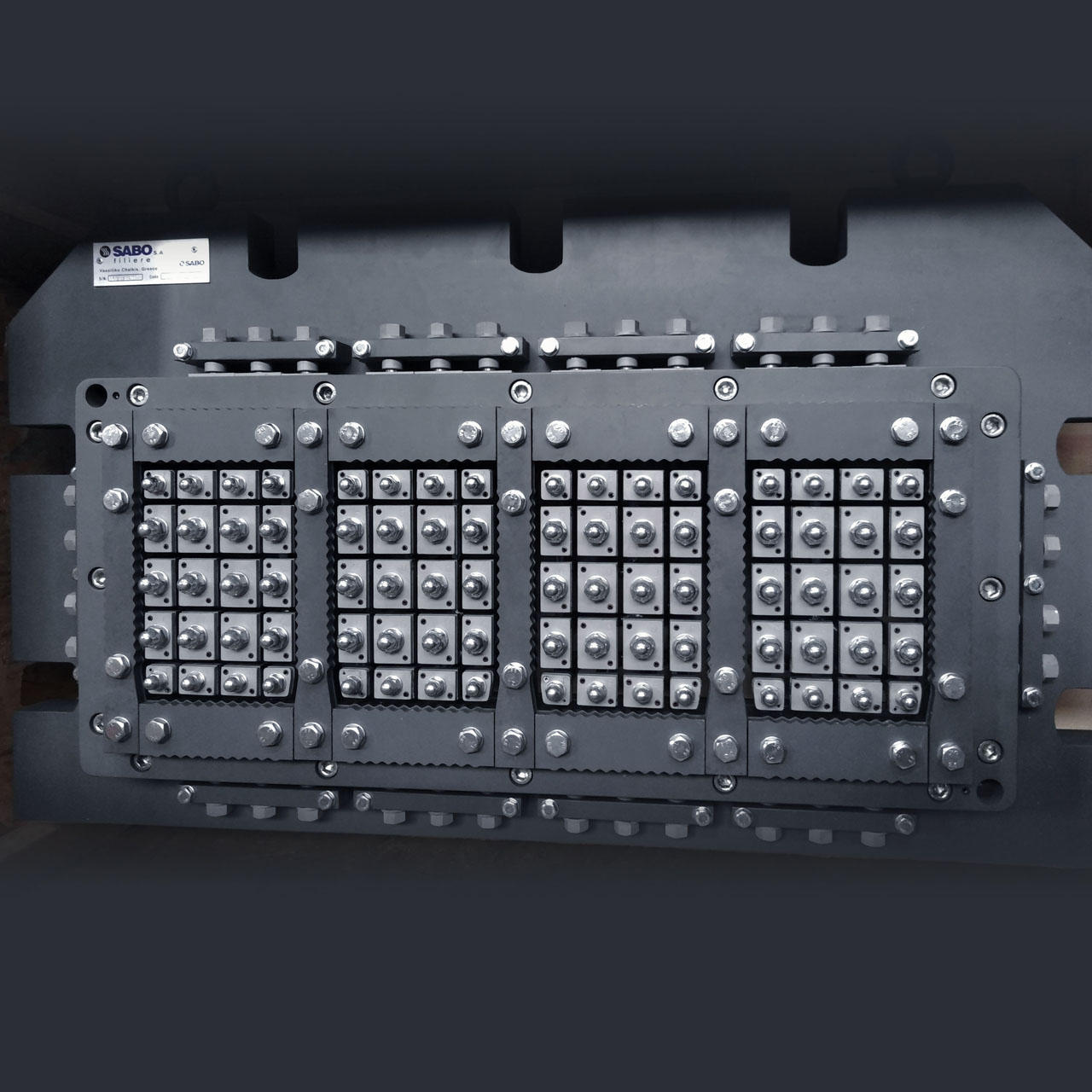

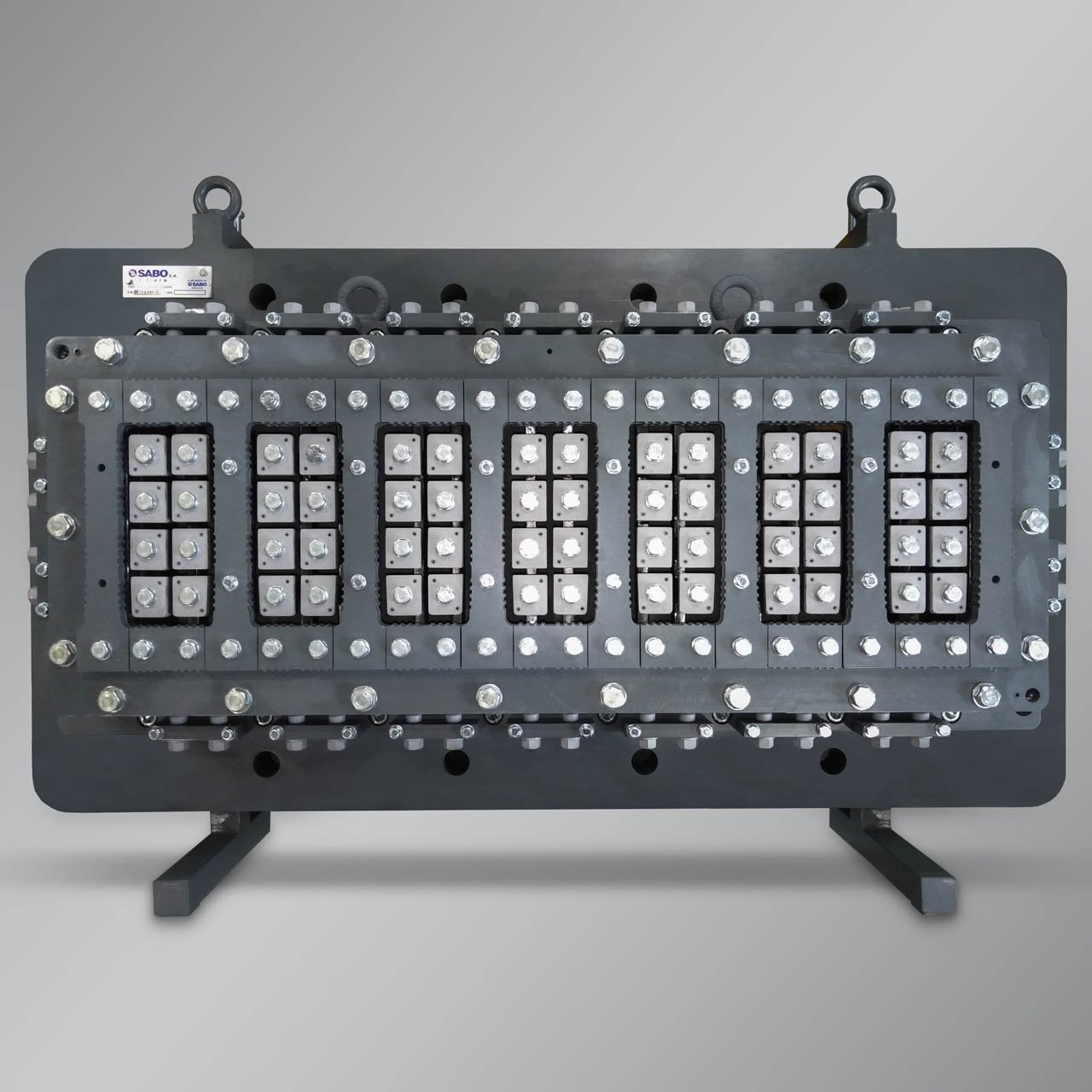

Solid and Facing Bricks

Dies for production of solid and facing bricks for high quality products. Optimized die design ensures uniform compaction, strength, and an excellent surface finish.

Thanks to the internal and external brake system, we offer precise, adaptable configurations for every customer.

Key Features:

- Conical part designed for ideal performance based on soil and extrusion characteristics

- Adjustable brakes (internal/external)

- Superior bridge support system for extrusion balance

- Easily interchangeable components

Technical Specifications:

- Metal body with reinforced plates and protective cones

- Hardened or chrome-plated inner cones

- Bridges and wearing plates from heat-treated or chrome-plated steel, ceramics, or tungsten carbide

- Basins of matching resistance

- Brakes with tungsten carbide or chrome lining

Compatible Die Types:

SFS, SFI-B1, SFM-B1, SFM-B2, SF-LSB

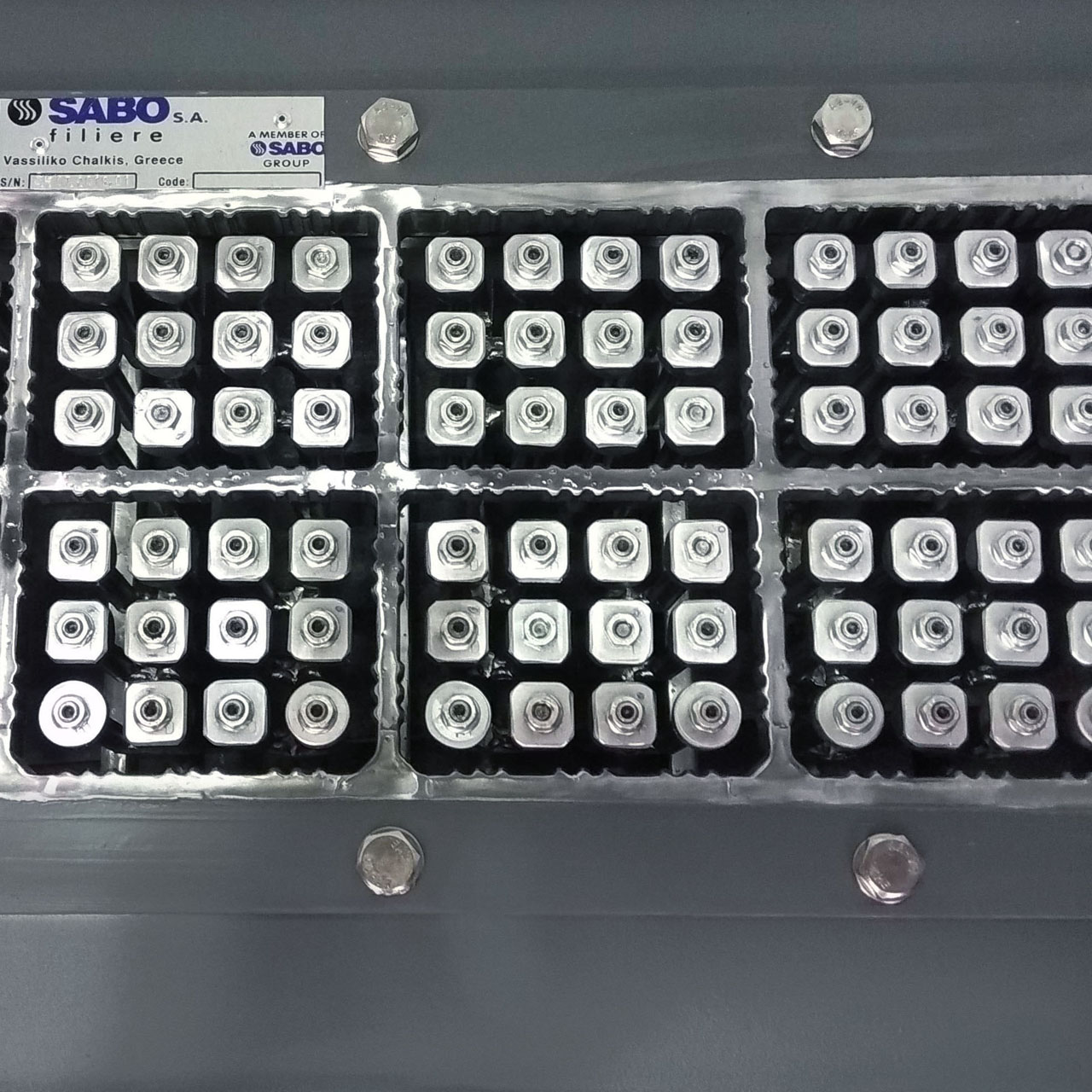

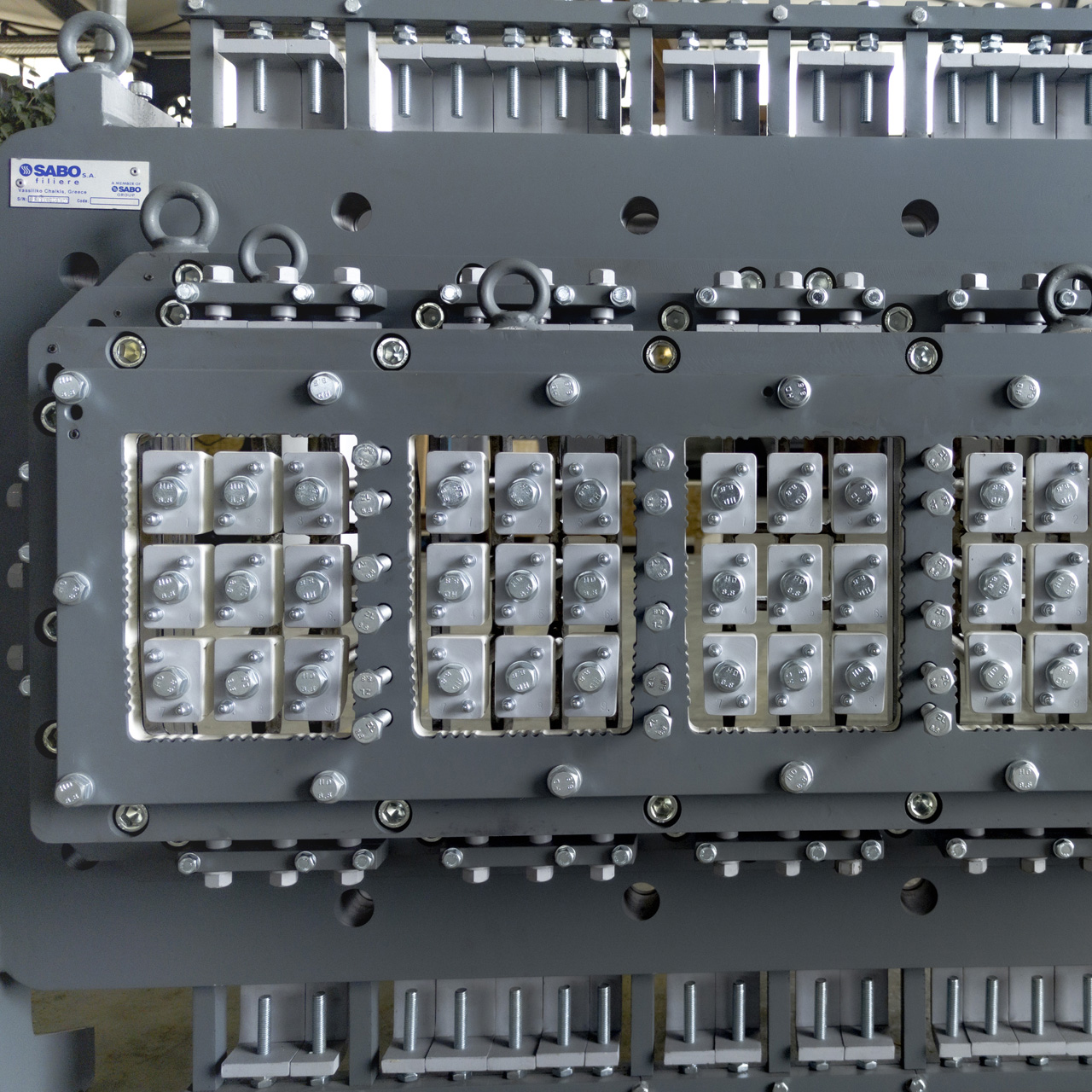

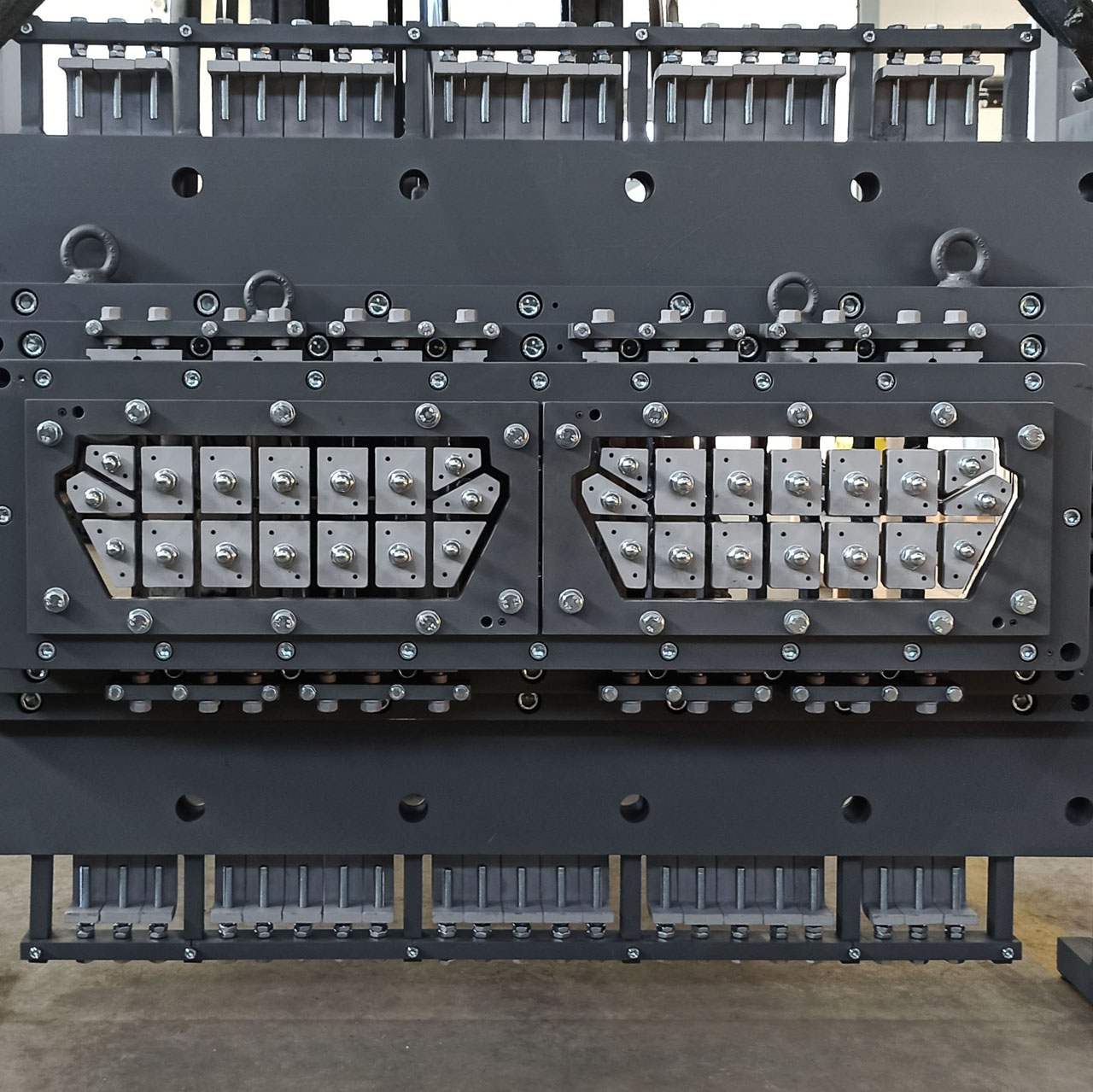

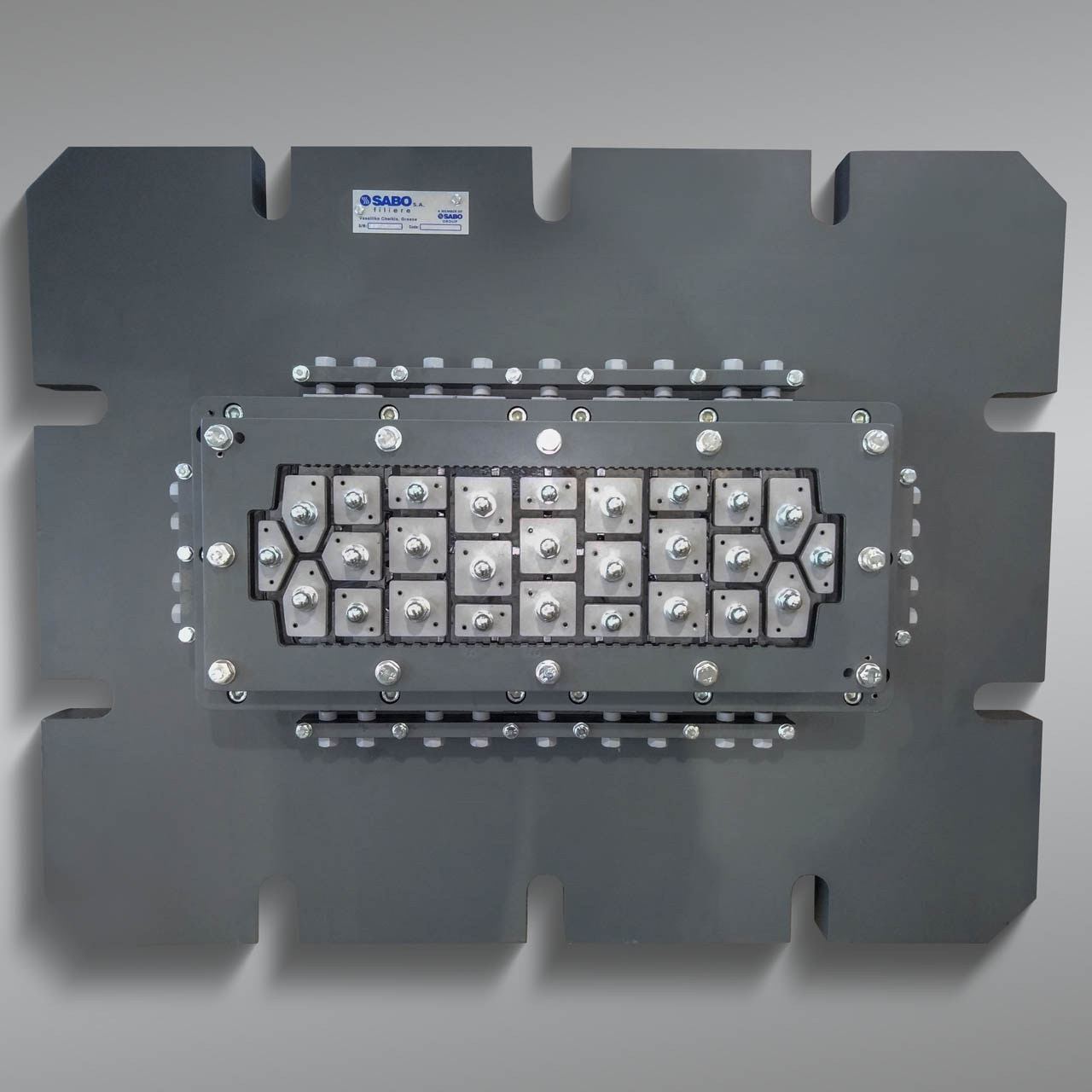

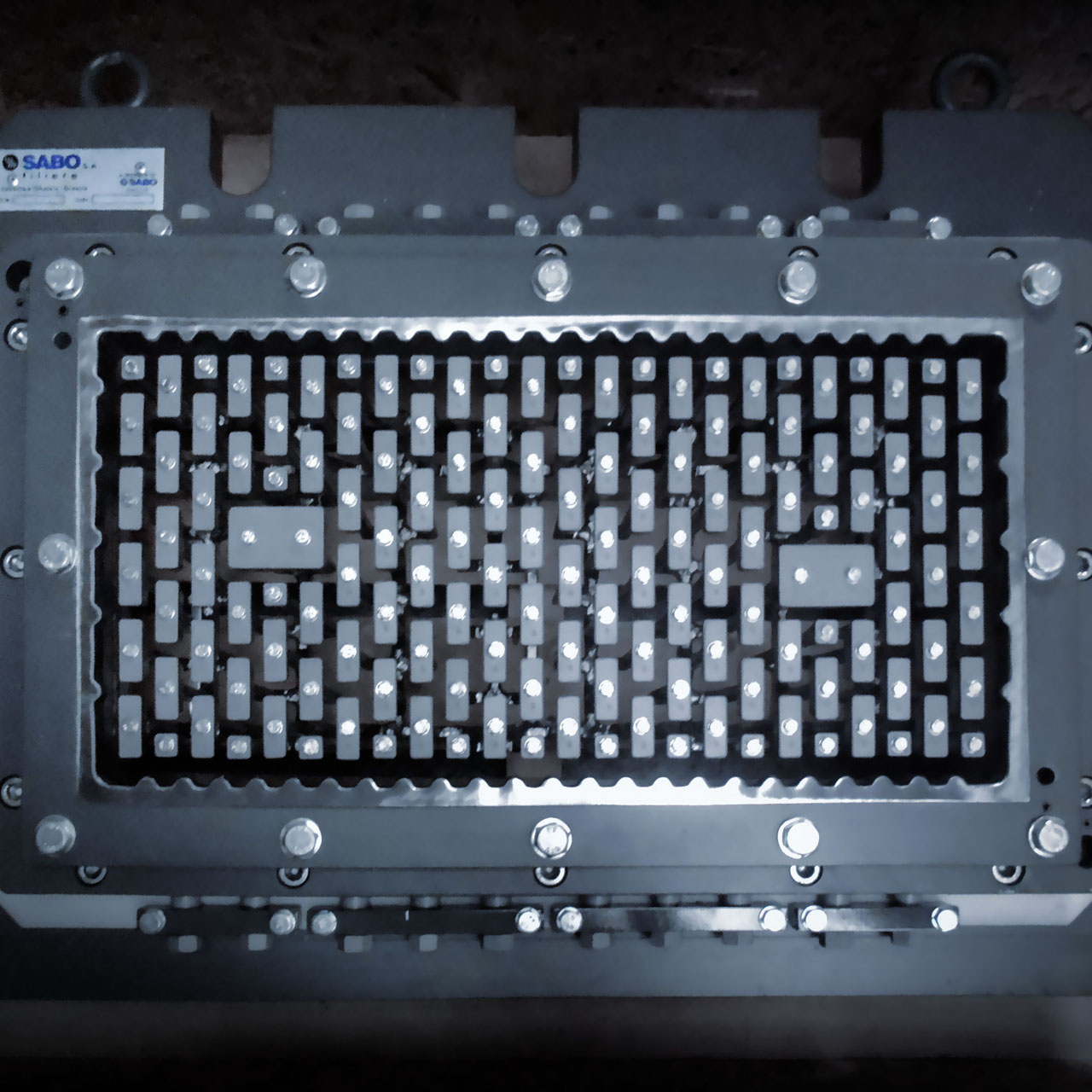

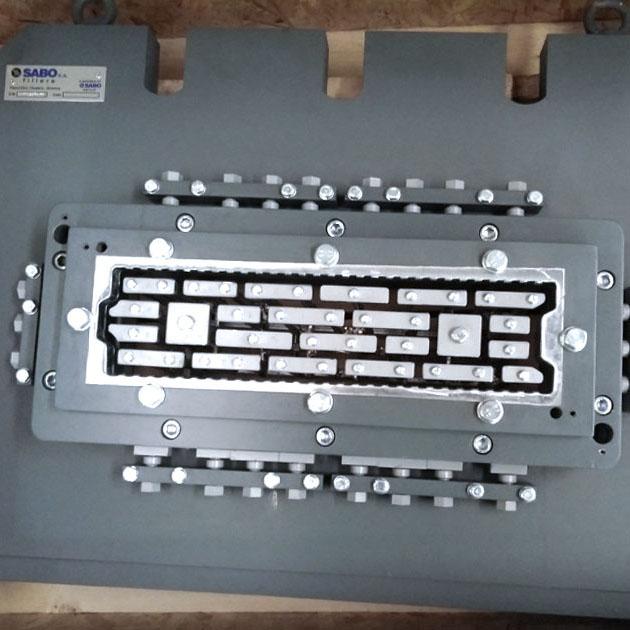

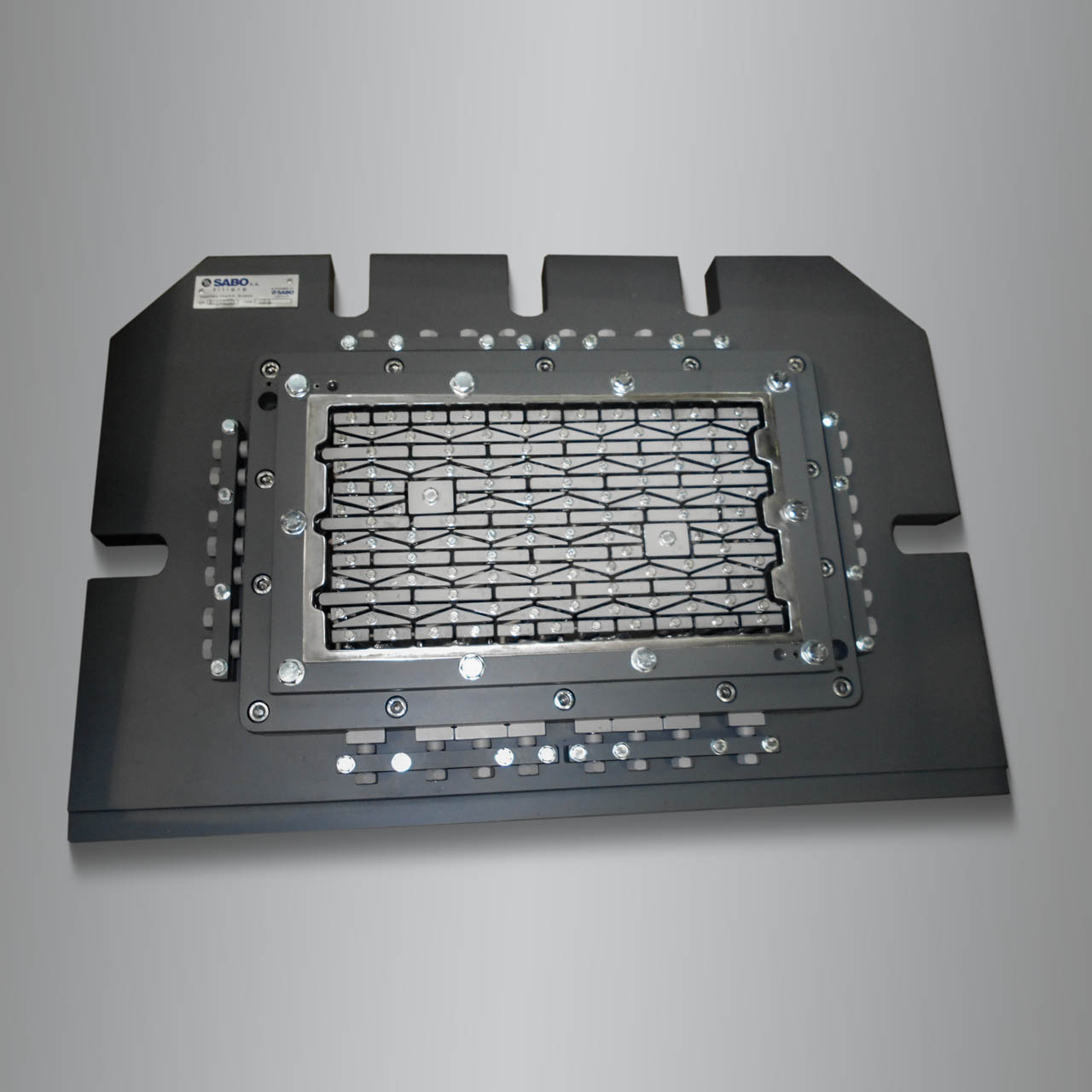

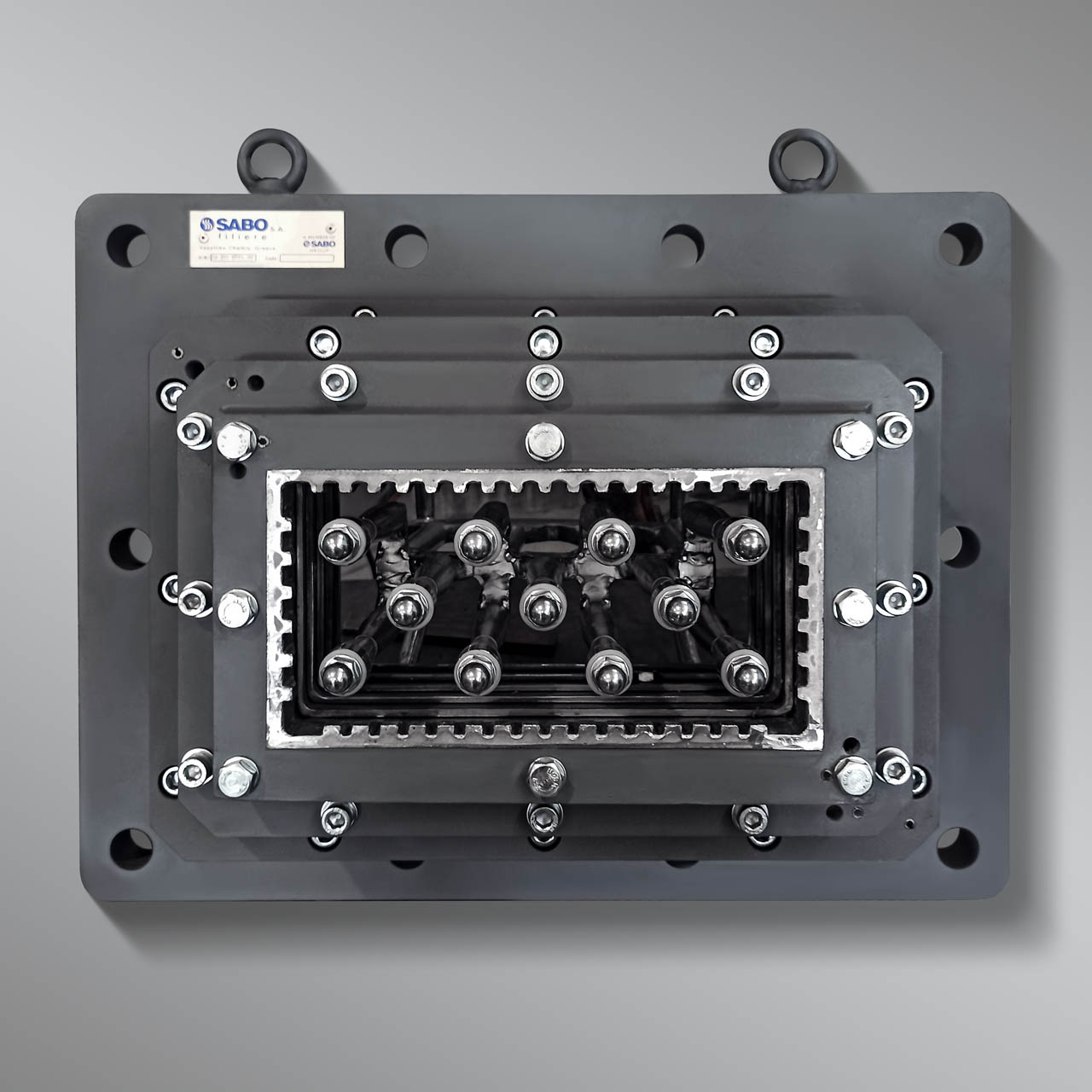

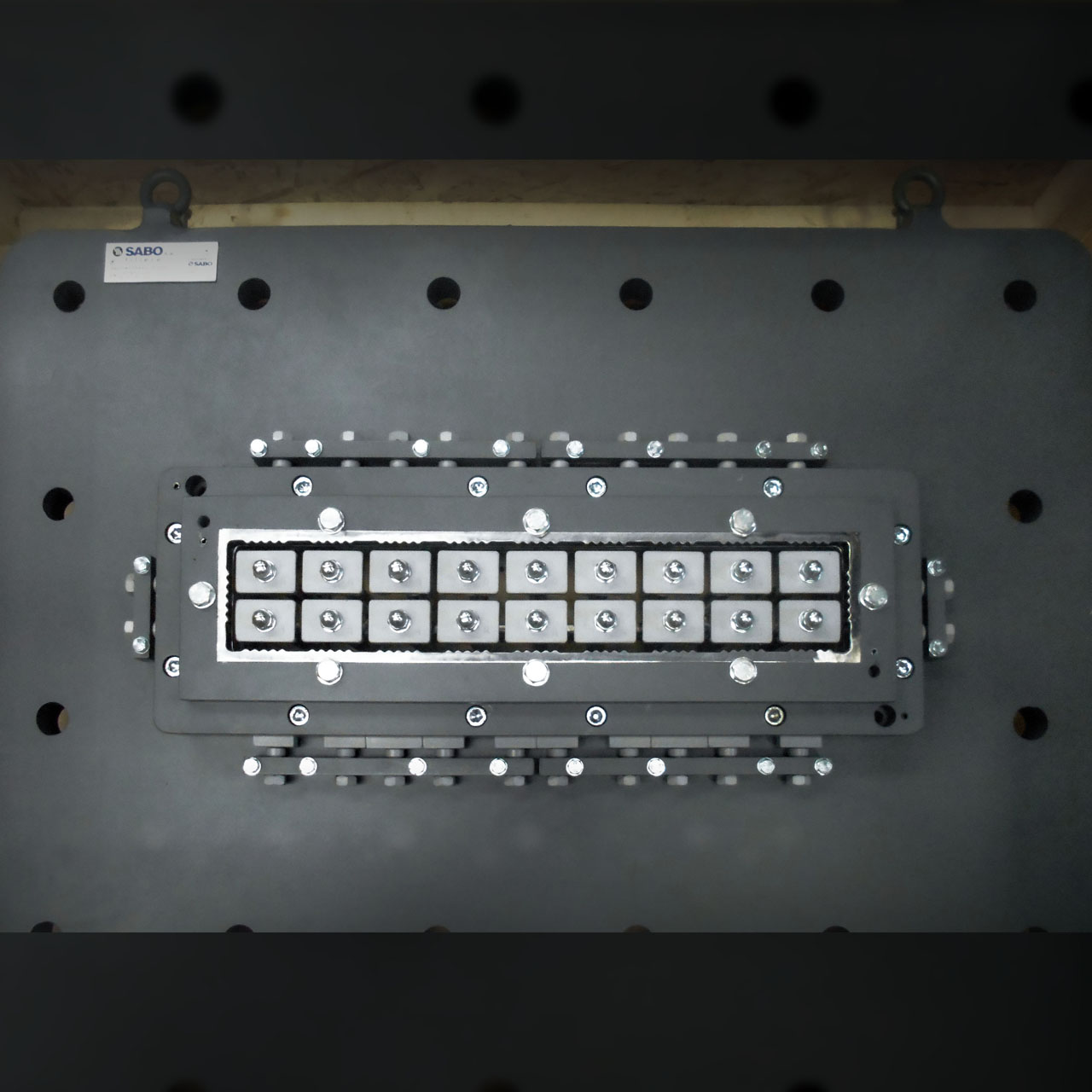

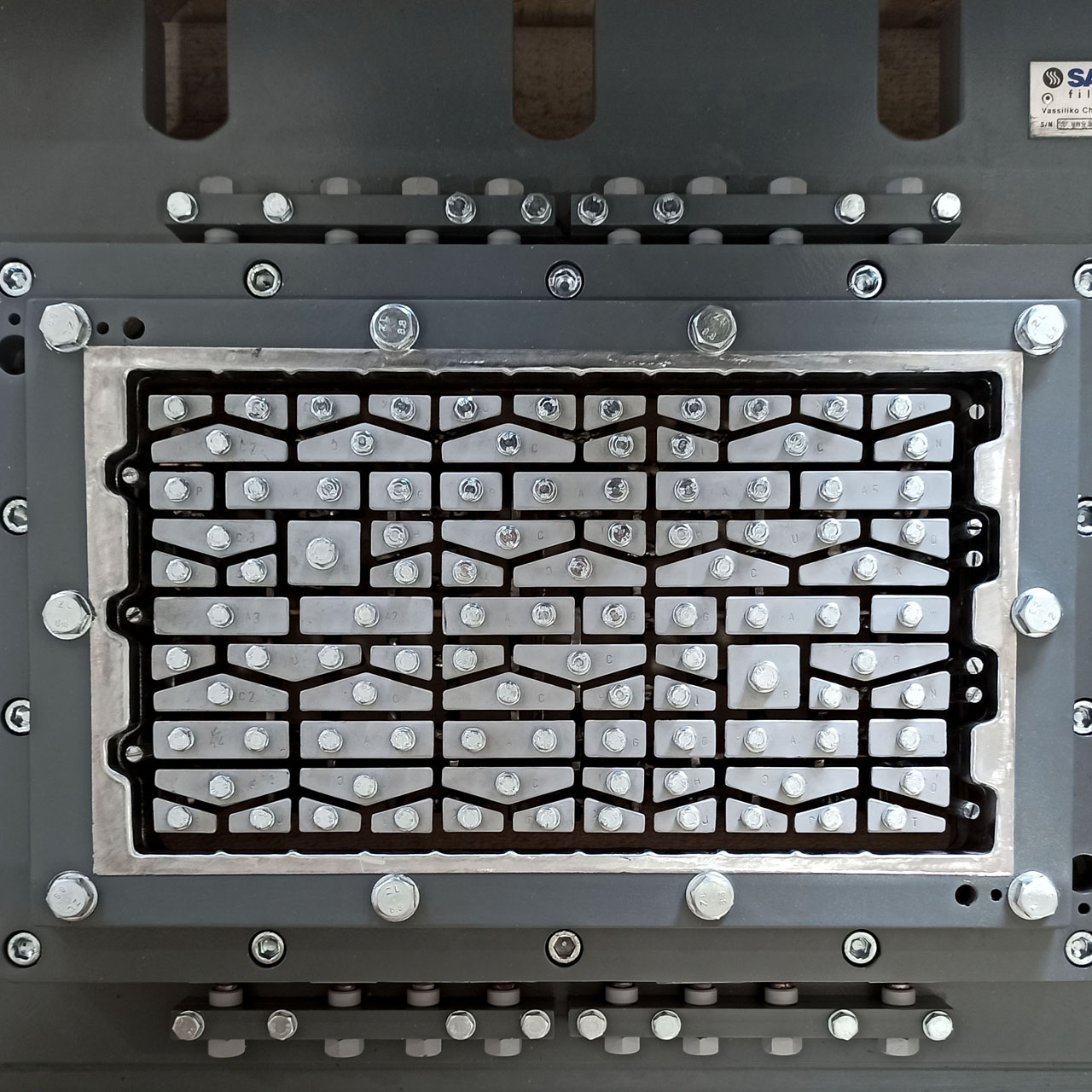

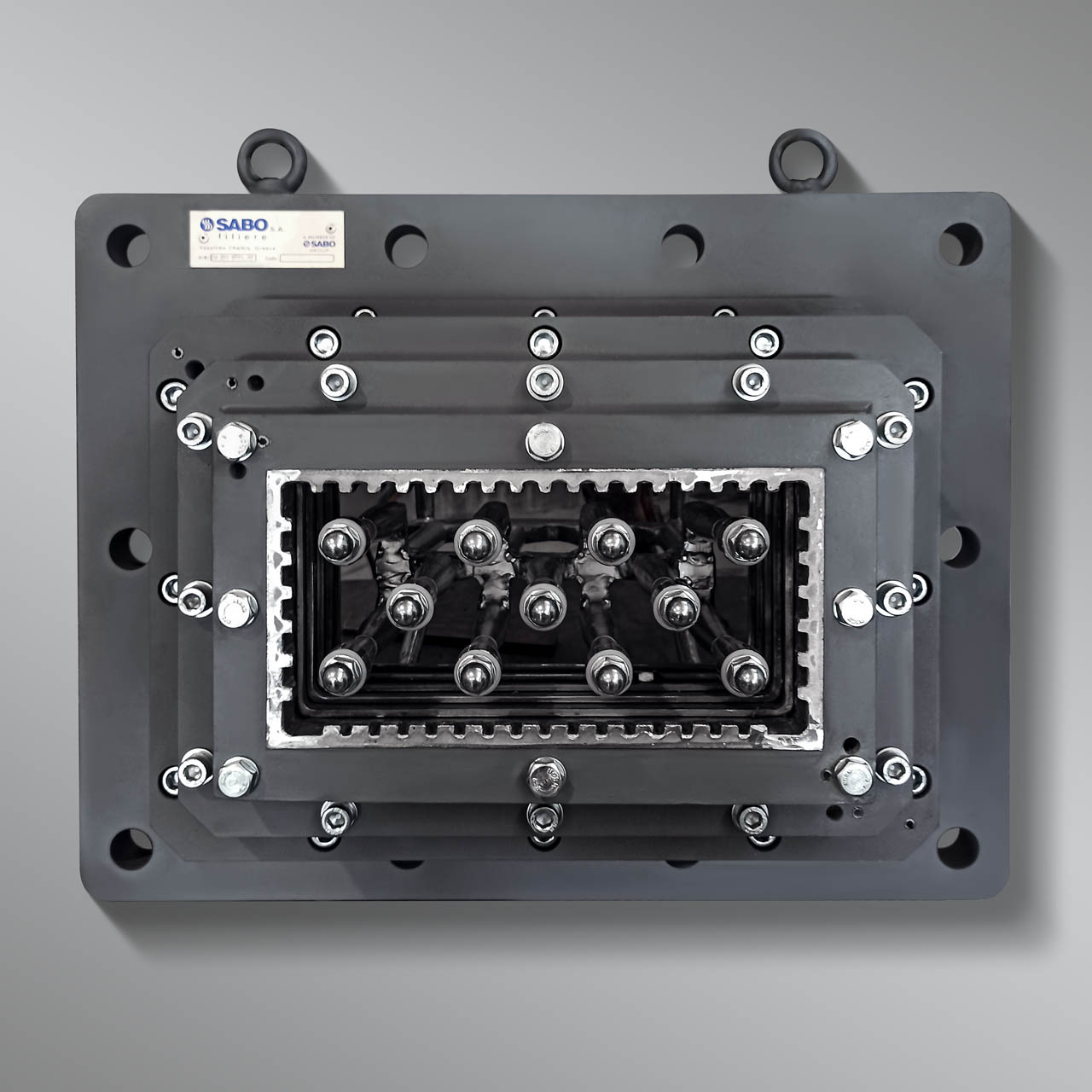

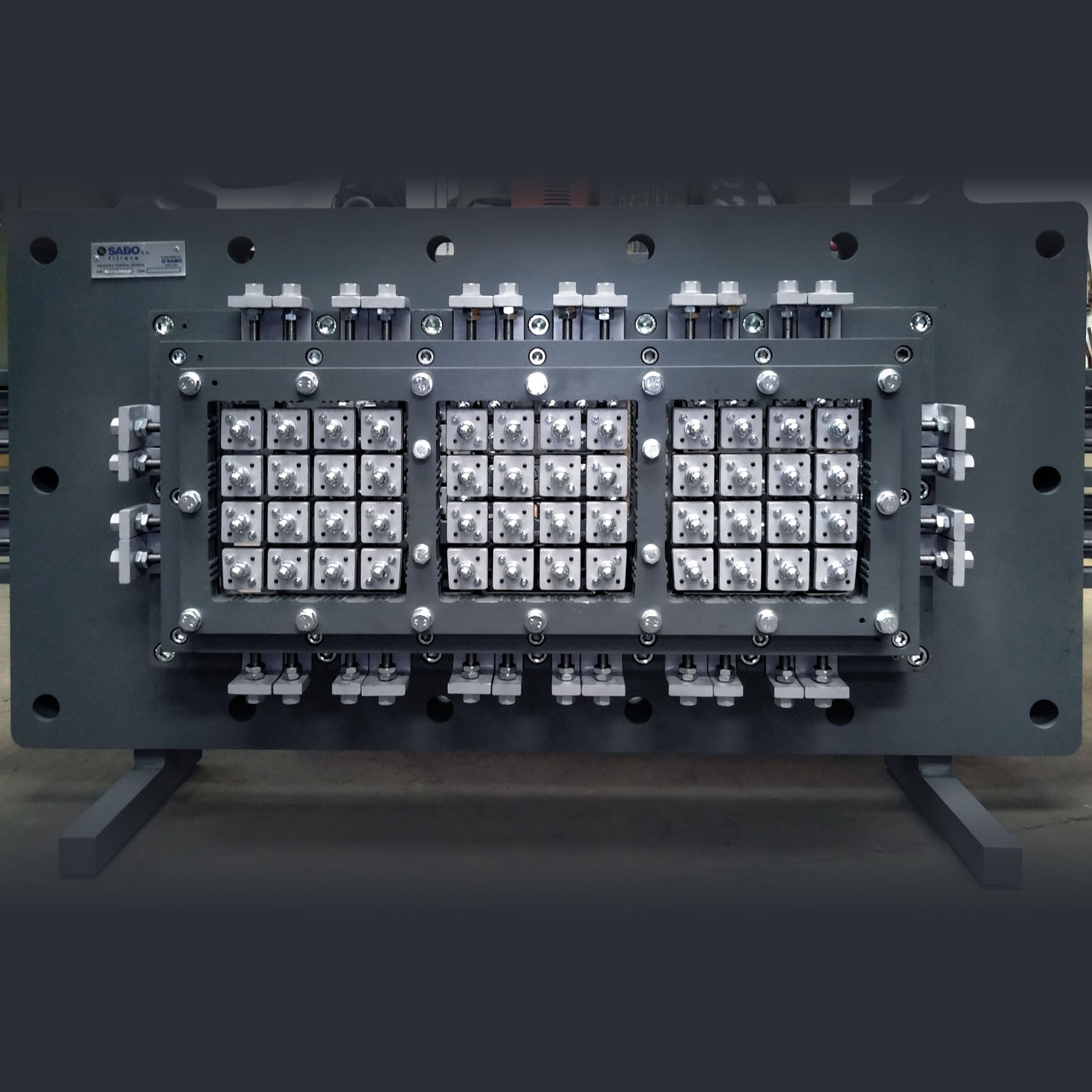

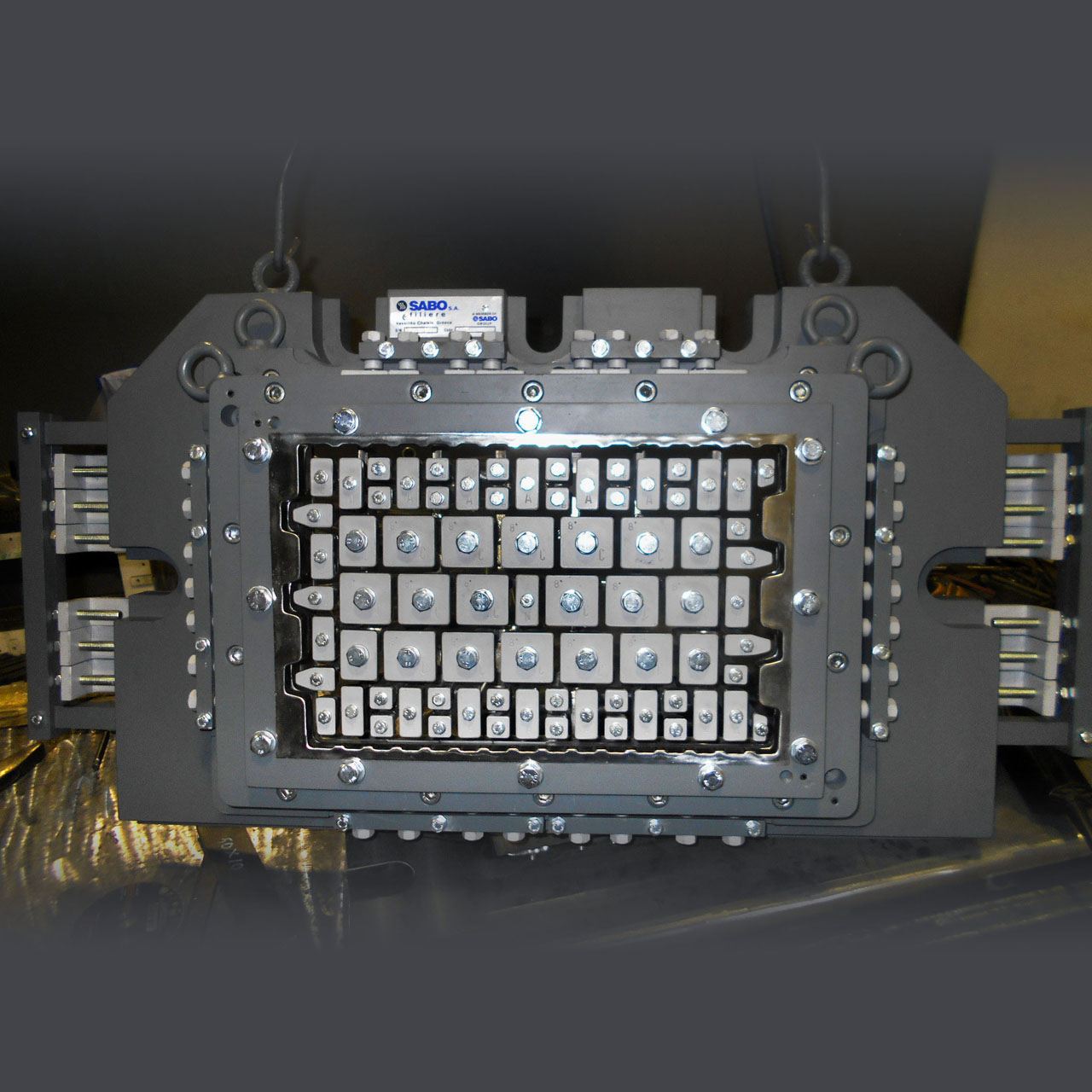

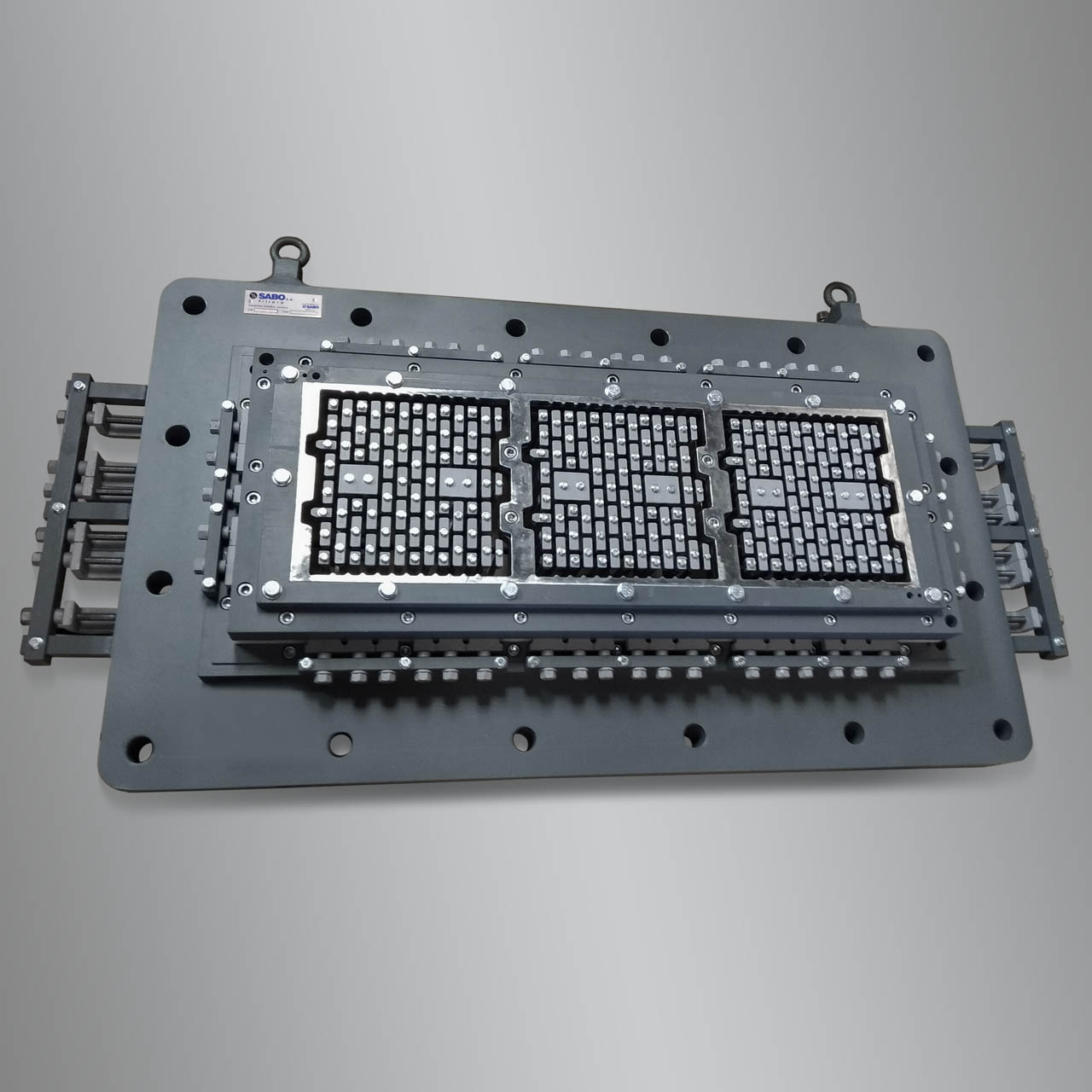

Split Tiles

Dies for the production of ceramic split tiles that require high construction quality and minimal dimensional tolerances.

The correct selection of materials is a key factor for achieving consistent product quality and ensuring long die life.

The use of specially designed brakes allows for easy and accurate adjustments during the extrusion process.

General Features:

- Short conical section, adapted to the clay and extrusion process properties, to ensure high final product quality

- Flexible adjustment using internal brakes

- Optimized design of the core holder for balanced extrusion

- All die components are easily replaceable

Technical Specifications:

- Metal die body combining hardened steel plates with internal protective liners for easy maintenance

- Ιnternal liners made of hardened steel or hard-chrome-plated steel

- Core holder made of hardened steel or hard-chrome-plated steel

- Cores made of heat-treated steel, chrome-plated steel, ceramic materials, or tungsten carbide

- Frames made of heat-treated steel, chrome-plated steel, ceramic materials, or tungsten carbide

- Internal brakes lined with tungsten carbide or hard chrome plating

Compatible Die Types:

SFS, SFI-B1

Tiles

Dies for the production of tiles that require high-quality construction with minimal tolerances.

As with split tiles, the selection of the appropriate raw materials plays a crucial role in ensuring consistent performance and long die life.

TypesΤύποι

- SFS

- SFI-B1

- SFM-B1

- SFM-B2

- SF-LSB

Type SFS

Dies with a simplified structural design, offering easy extrusion with minimal energy consumption. They are ideal for clays with low drying sensitivity, provided that high extrusion stability and clay preparation quality are ensured.

The internal brake system allows for precise flow regulation and optimal balance.

General Features:

- Small conical section to minimize friction losses

- Easy adjustments via internal brakes

- Fully replaceable components for effortless maintenance

Technical Specifications:

- Metal die body with internal protective liners for easy maintenance

- Liners made of hardened steel or hard-chrome-plated steel

- Core holders made of hardened or chrome-plated steel

- Cores and frames made of heat-treated steel, chrome-plated steel, ceramic materials, or tungsten carbide

- Internal and external brakes lined with tungsten carbide or hard chrome plating

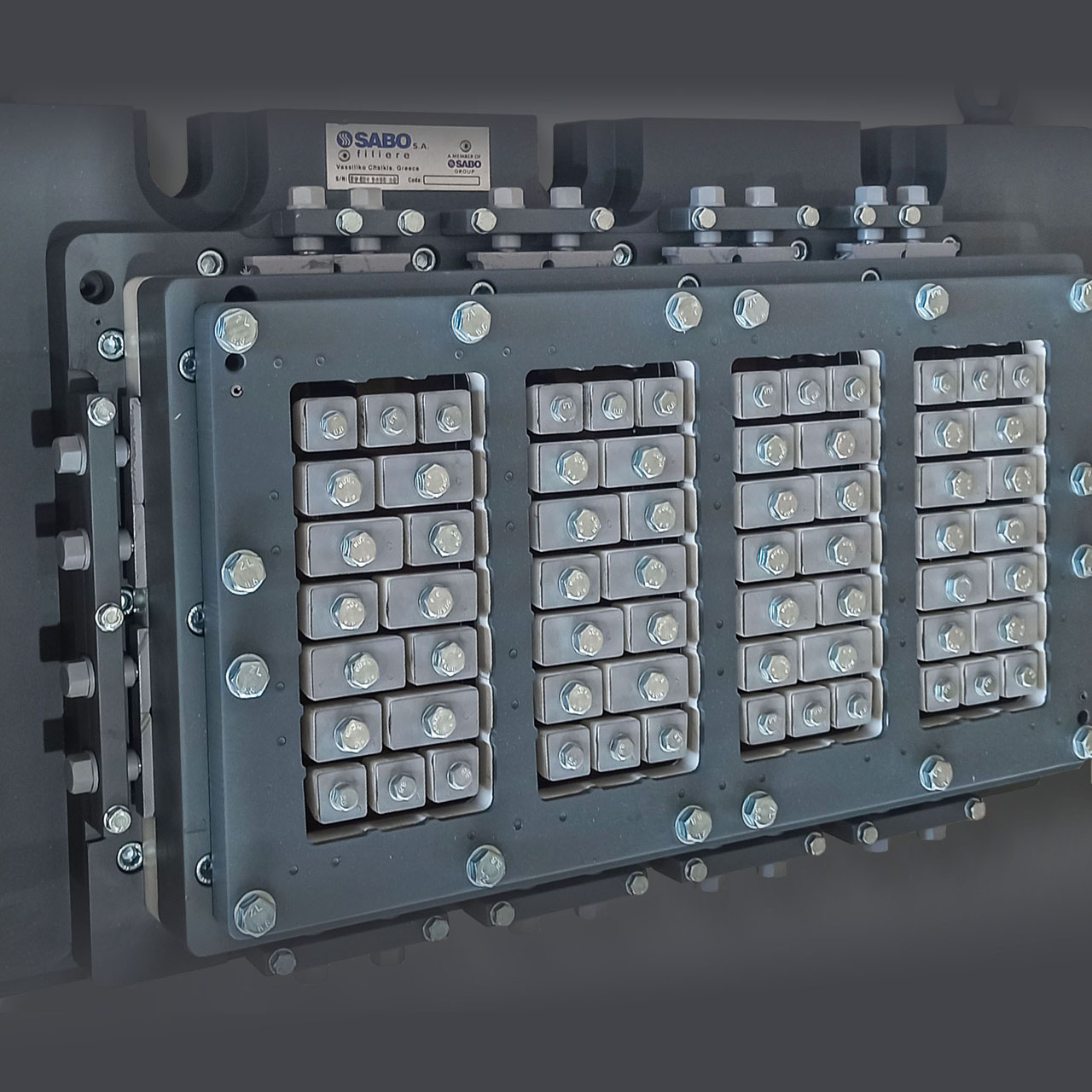

Type SFI-B1

Dies with a medium conical section, ideal for the production of all brick types. They offer an excellent balance between uniform clay extrusion and high productivity, ensuring durable, high-quality final products.

Easy and precise adjustments through external and internal brakes allow for full customization according to each production line’s requirements.

General Features:

- Medium conical part, optimized for the properties of the clay and extrusion process

- Flexible adjustments via internal and external brakes

- Optimized design of the core holder for balanced extrusion and high performance

- Fully replaceable parts for easy maintenance

Technical Specifications:

- Metal die body with a combination of hard steel plates and internal protection liners for easy maintenance

- Internal liners and core holders made of hardened or hard-chrome-plated steel

- Cores and frames made of heat-treated steel, chrome-plated steel, ceramic materials, or tungsten carbide

- Internal and external brakes lined with tungsten carbide or hard chrome plating

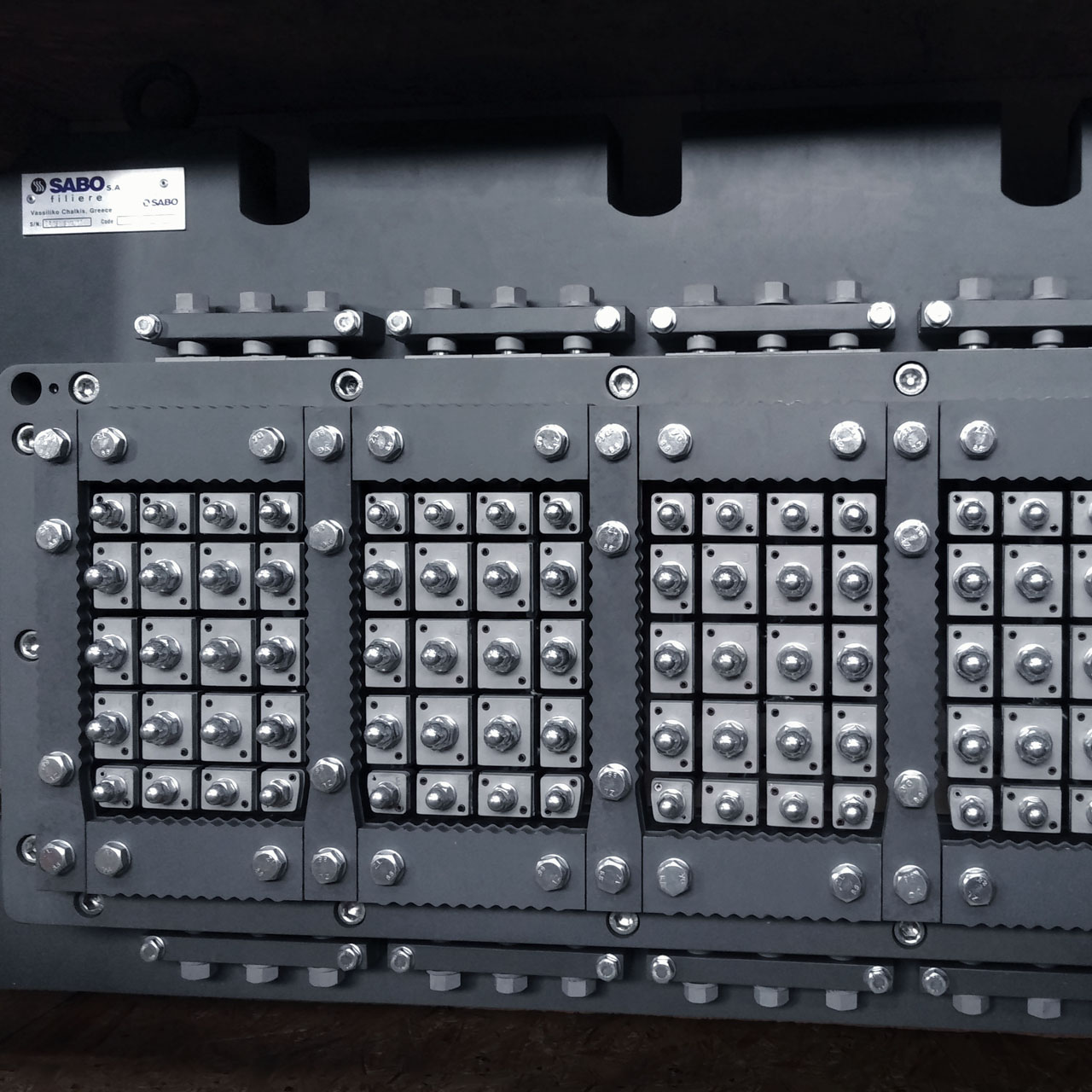

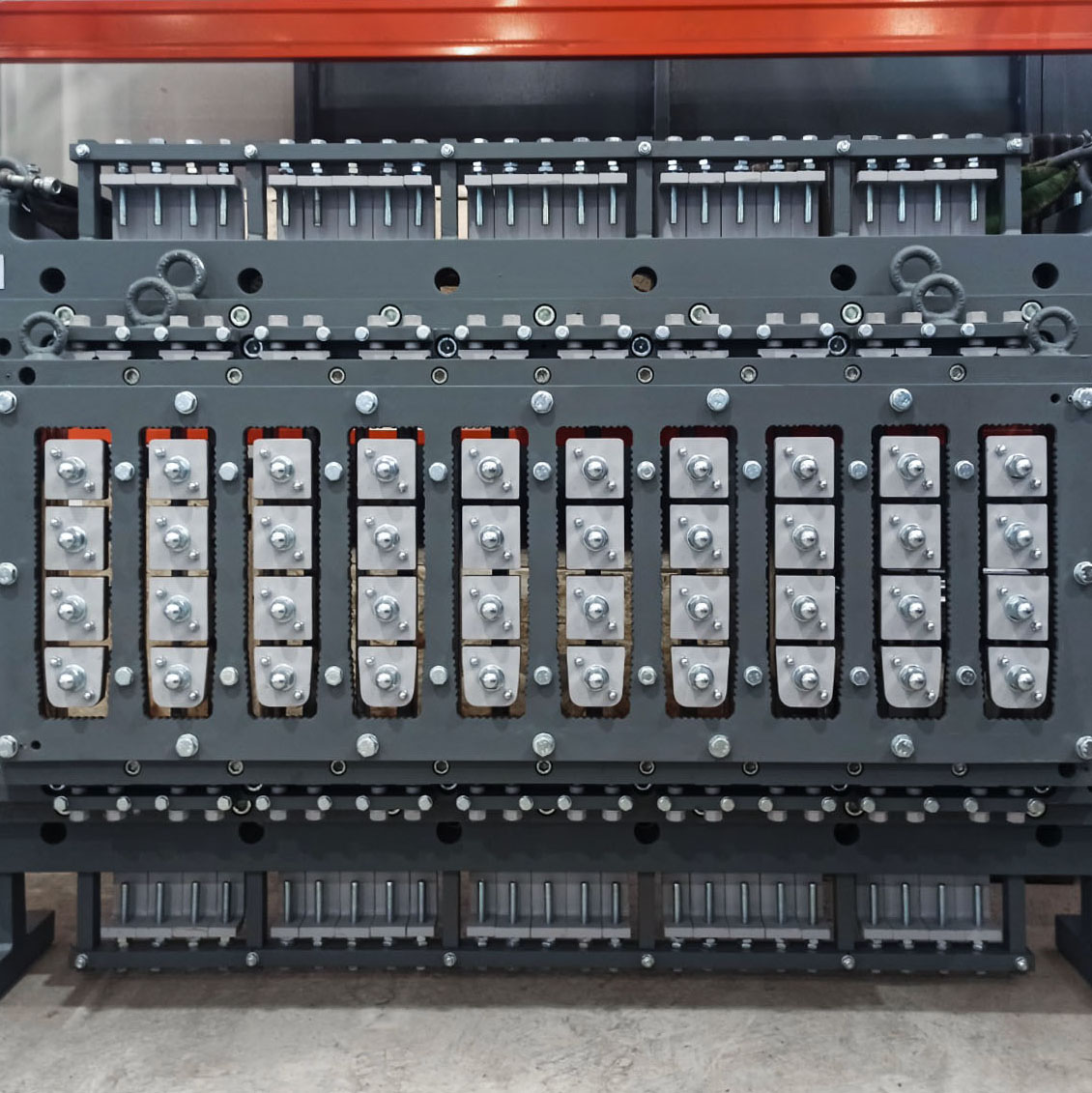

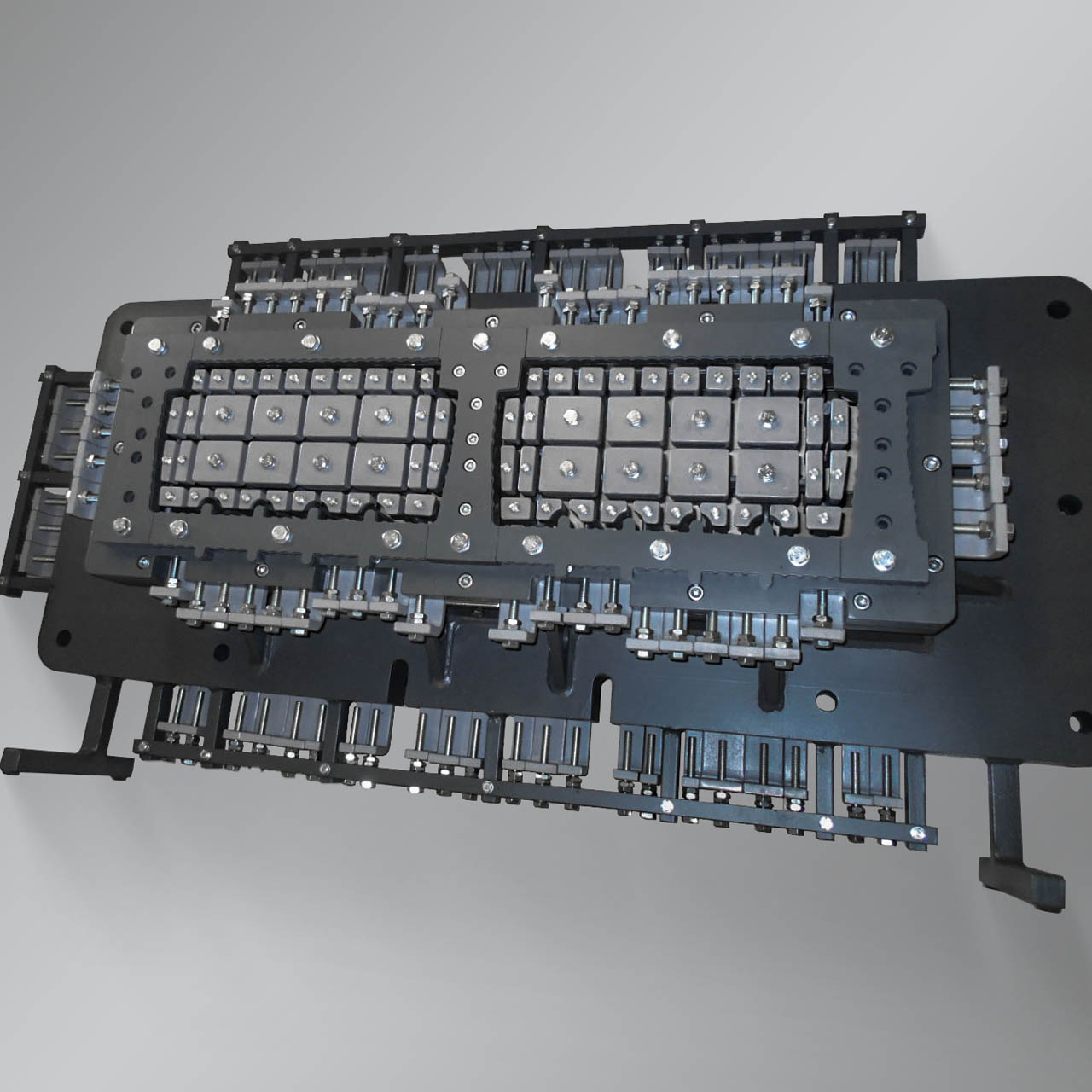

Type SFM-B1

Dies with an extended conical section, specifically designed to achieve high clay compression and optimal extrusion stability.

This type is ideal for multi-exit dies, as it reduces clay humidity fluctuations and ensures consistently strong, uniform products.

Precise and flexible adjustments can be made using both internal and external brakes, allowing full adaptation to each production setup.

General Features:

- Long conical part for maximum compression and extrusion stability

- Flexible adjustments via external and internal brakes

- Excellent extrusion balance with uniform column exit speed

- Fully replaceable components for efficient maintenance

Technical Specifications:

- Die body constructed from metal with reinforced steel plates and internal protective liners for ease of maintenance

- Internal liners and core holders made of hardened or hard-chrome-plated steel

- Cores and frames made of heat-treated steel, chrome-plated steel, ceramic materials, or tungsten carbide

- Internal and external brakes lined with tungsten carbide or hard chrome plating

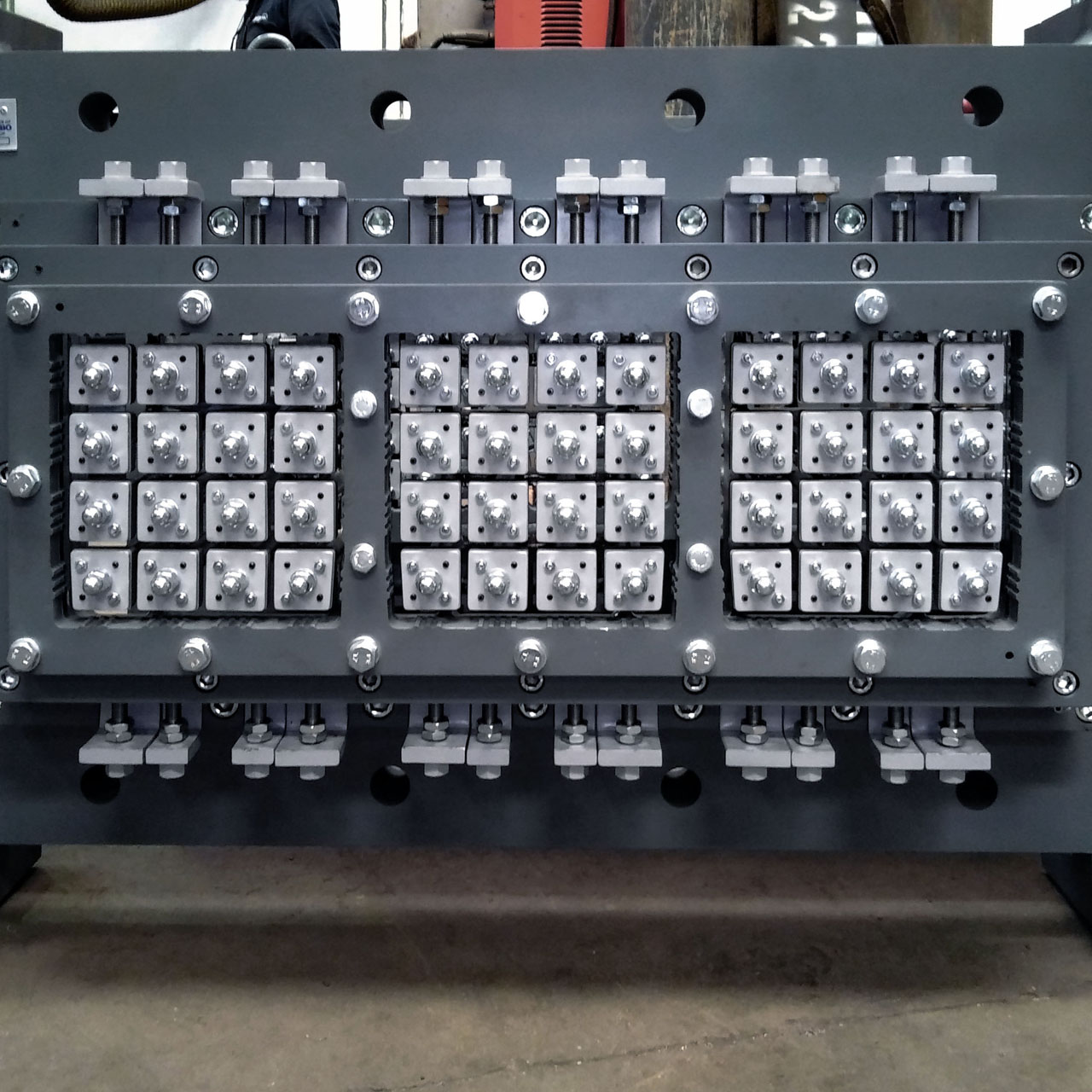

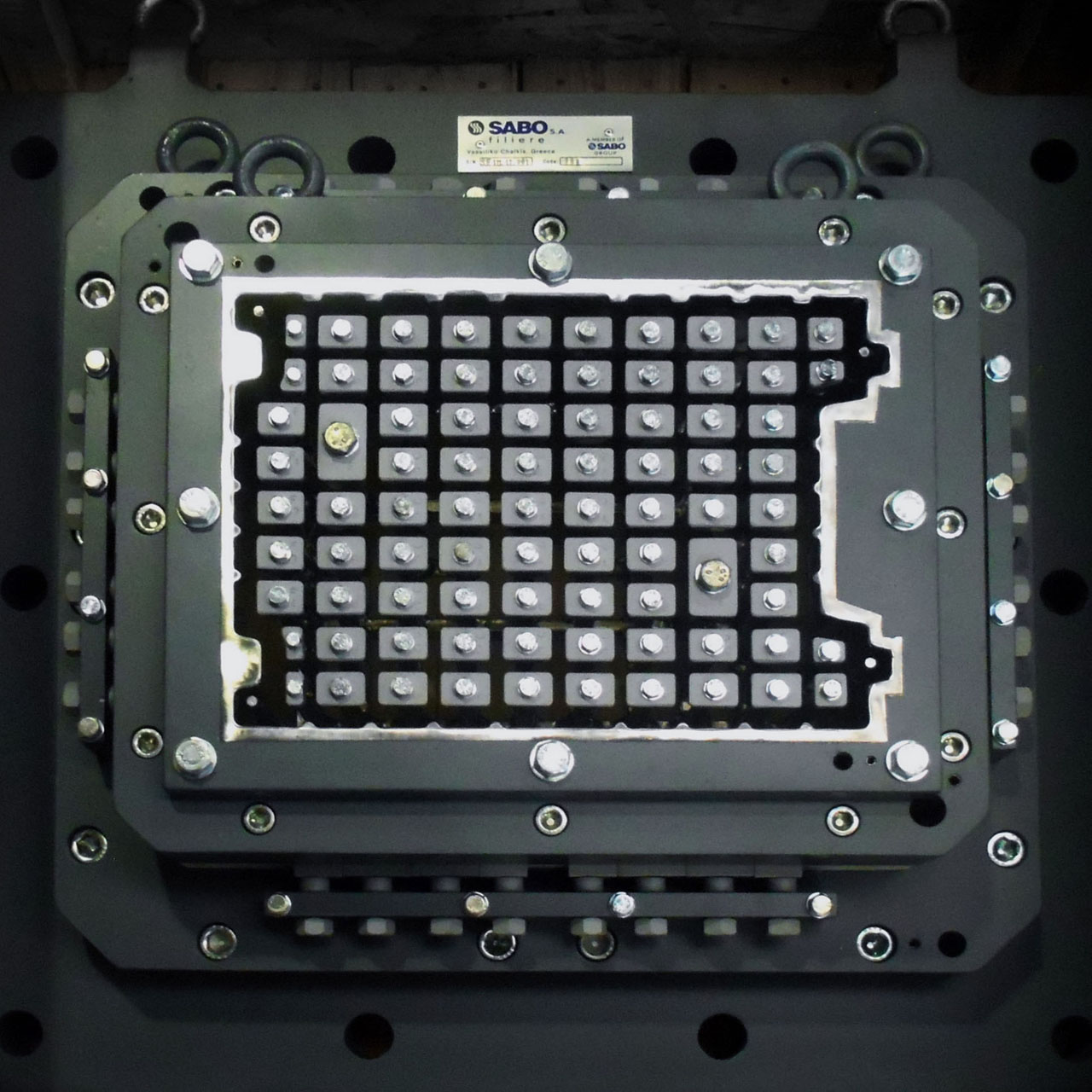

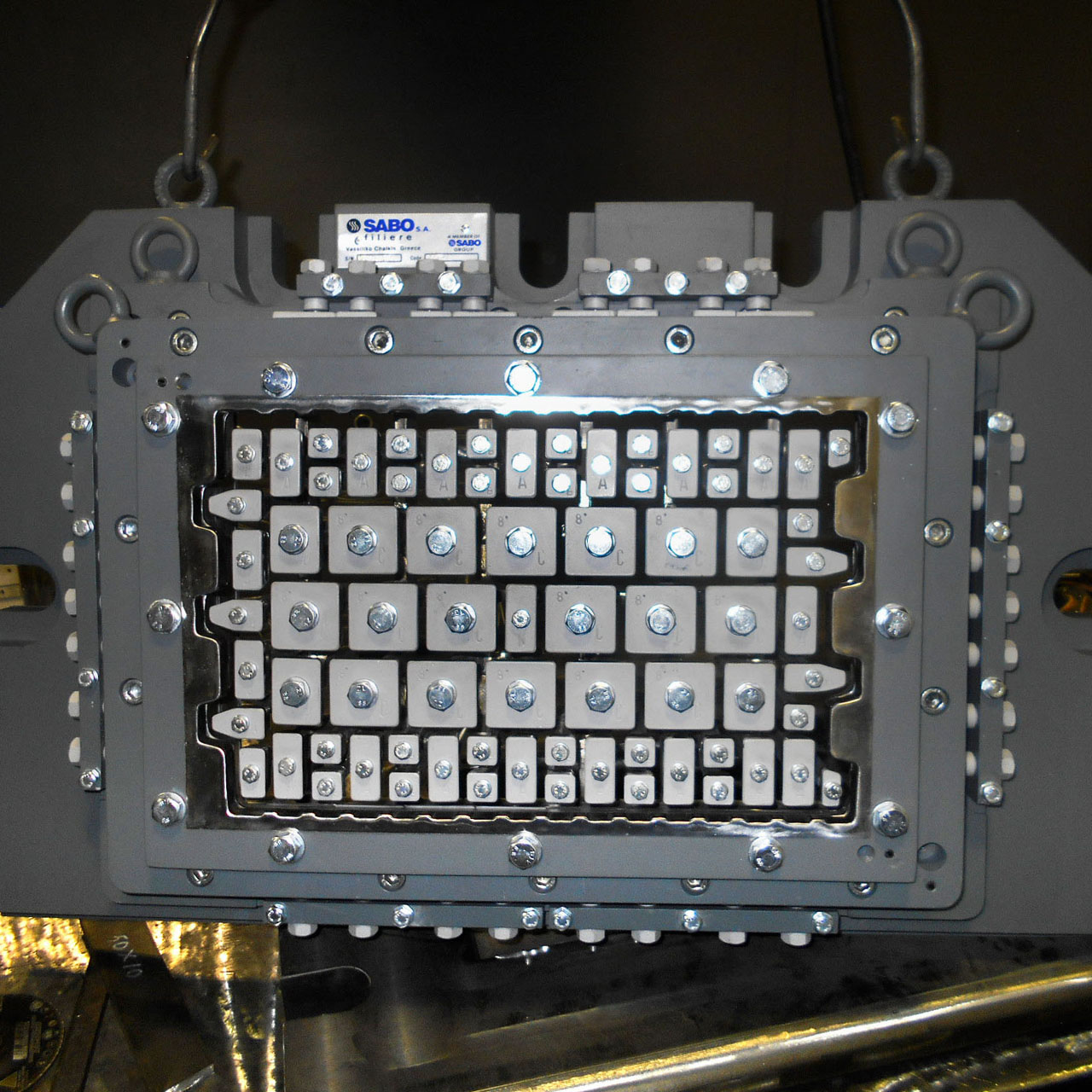

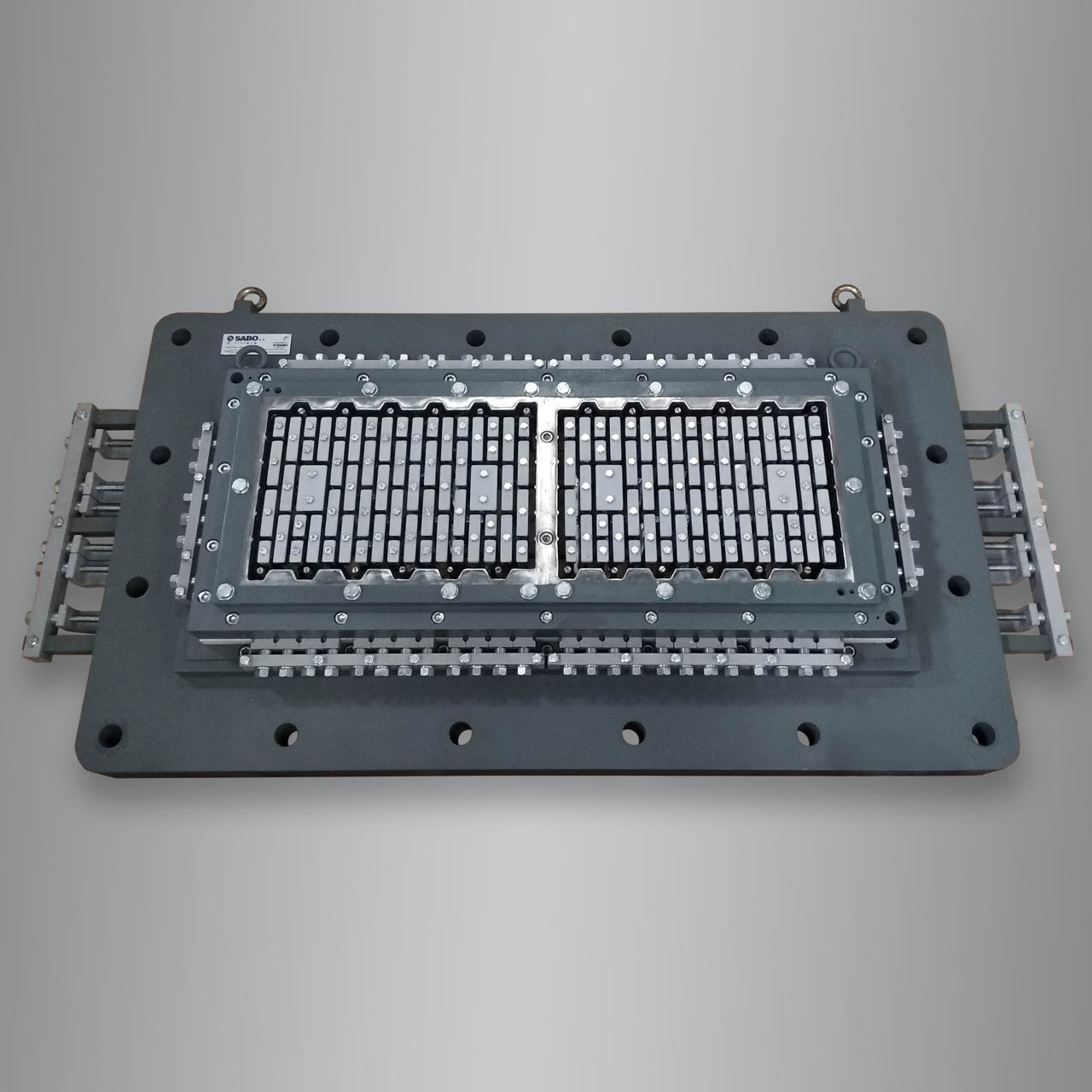

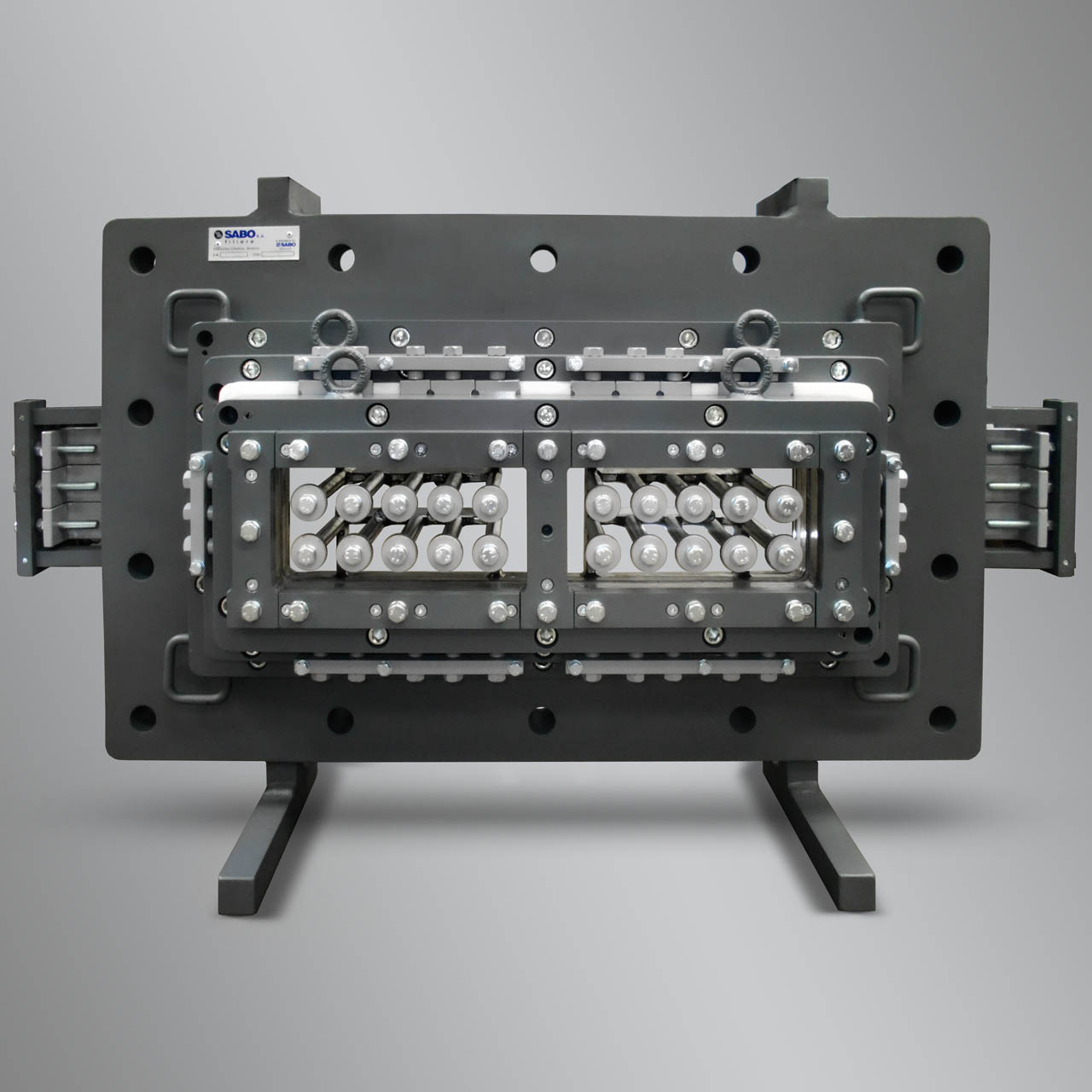

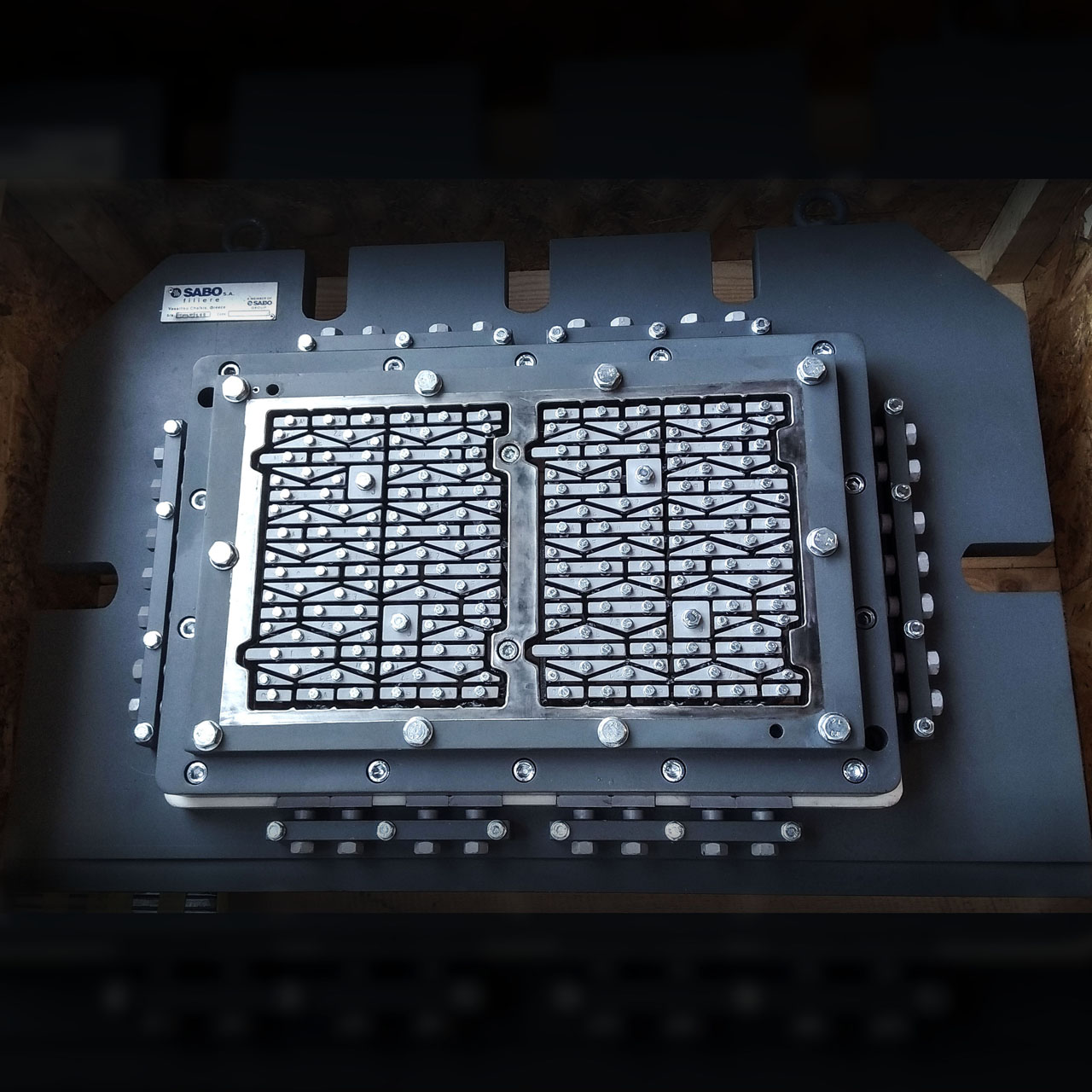

Type SFM-B2

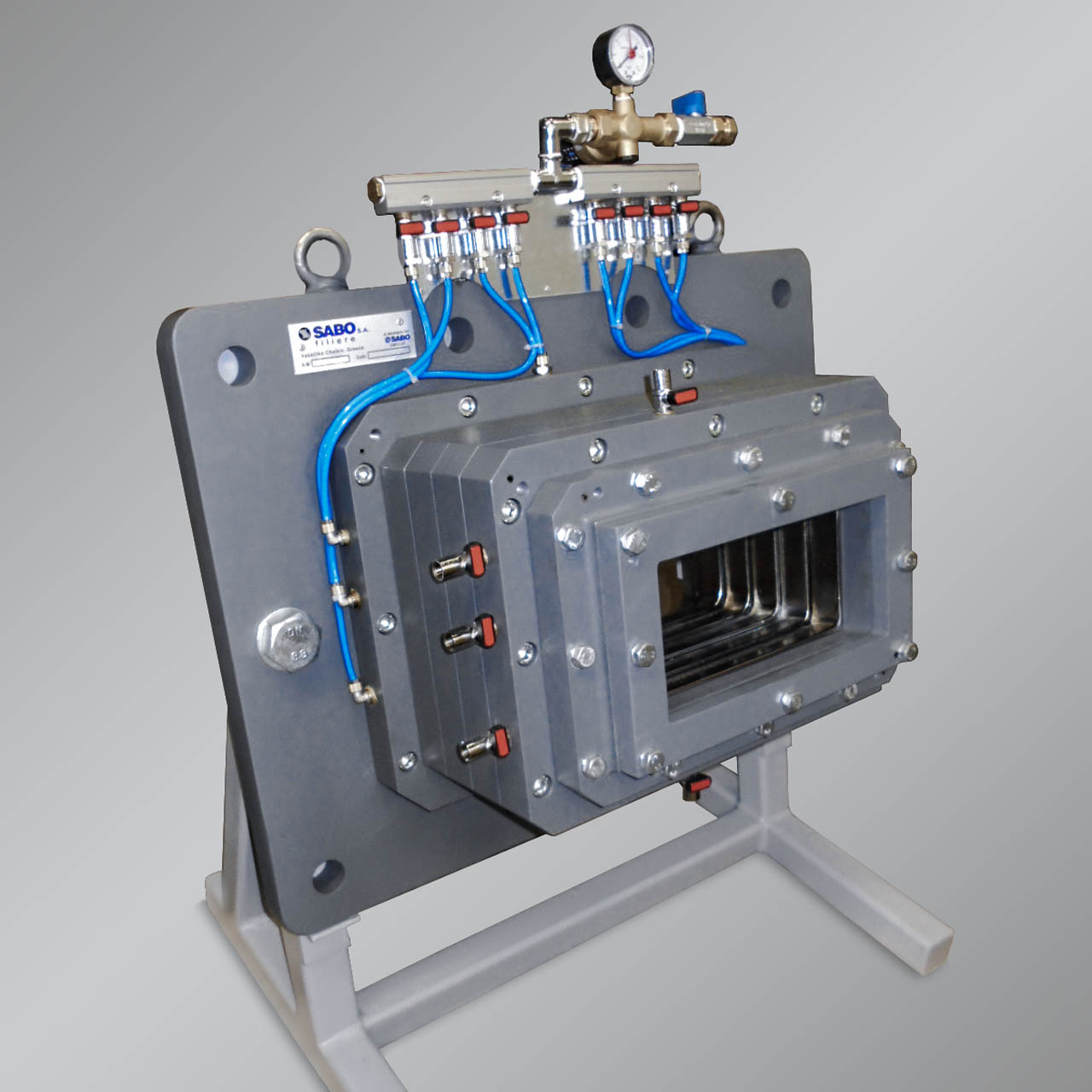

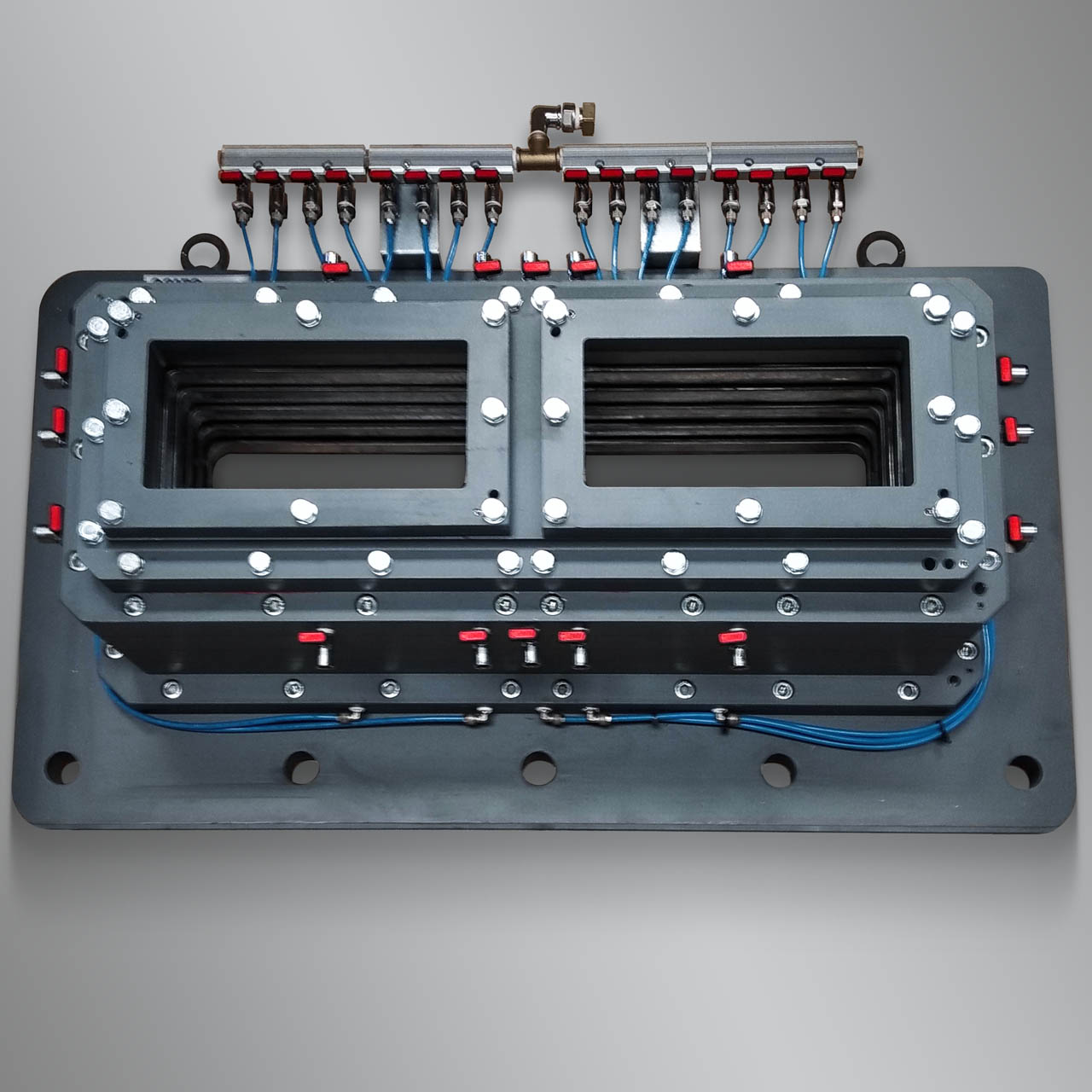

An advanced version of the SFM-B1 die, featuring additional rear external brakes that offer enhanced flexibility and efficiency in clay flow regulation.

All adjustments can be made in real time, during production, without requiring die disassembly — minimizing downtime and maximizing performance.

This is the ideal solution for production environments that demand quick adaptability and consistent extrusion quality.

General Features:

- Extended conical section for high compression and extrusion stability

- Full control through front and rear external brakes for precise, real-time adjustments

- Uniform column exit speed, ideal for multi-exit die configurations

- All die components are easily replaceable, enabling fast and cost-effective maintenance

Technical Specifications:

- Metal body with reinforced hard steel plates and internal protection liners for easy maintenance

- Internal liners and bridges made of hardened or hard-chrome-plated steel

- Cores and frames made of heat-treated steel, chrome-plated steel, ceramics, or tungsten carbide

- Internal and external brakes with tungsten carbide hard facing or hard chrome plating

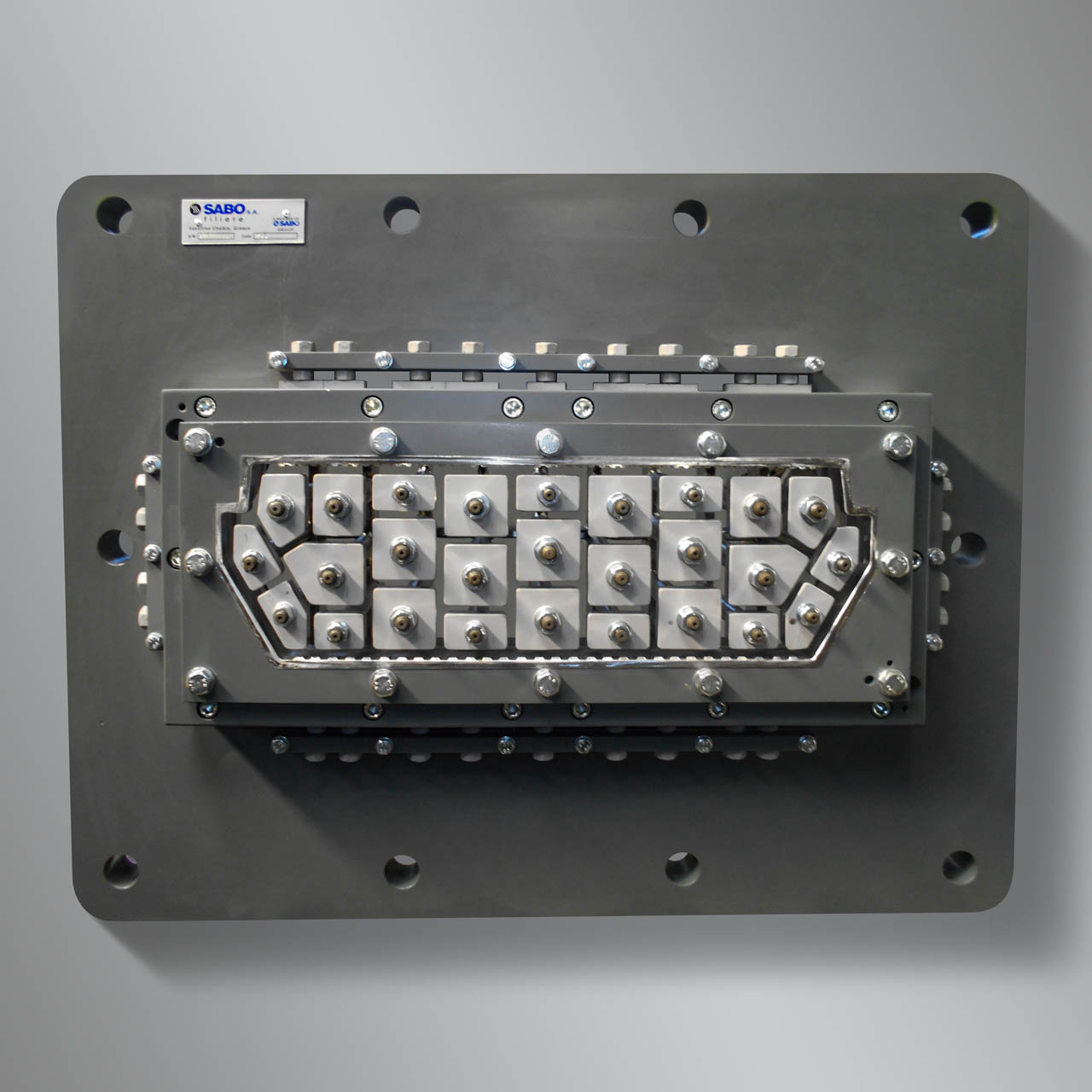

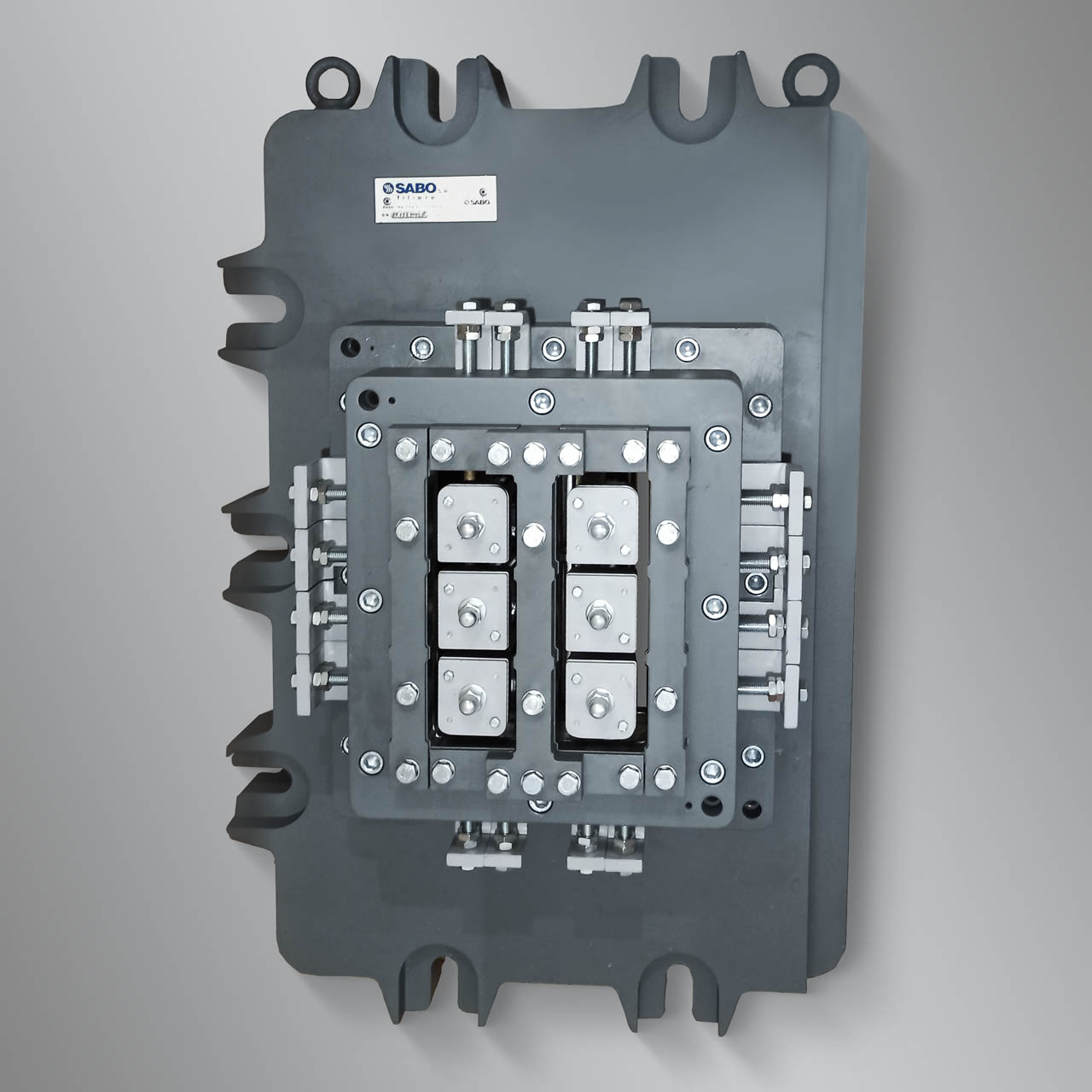

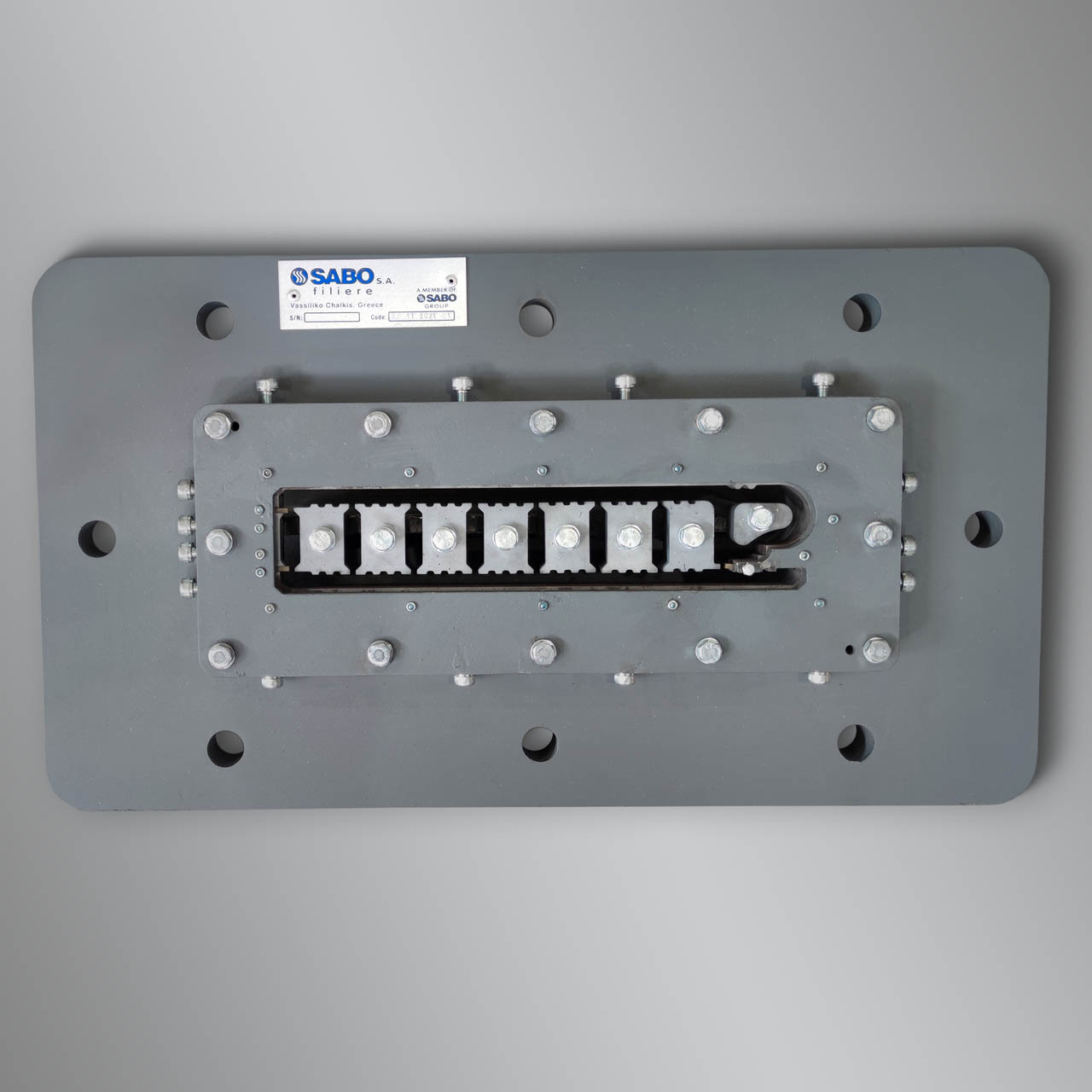

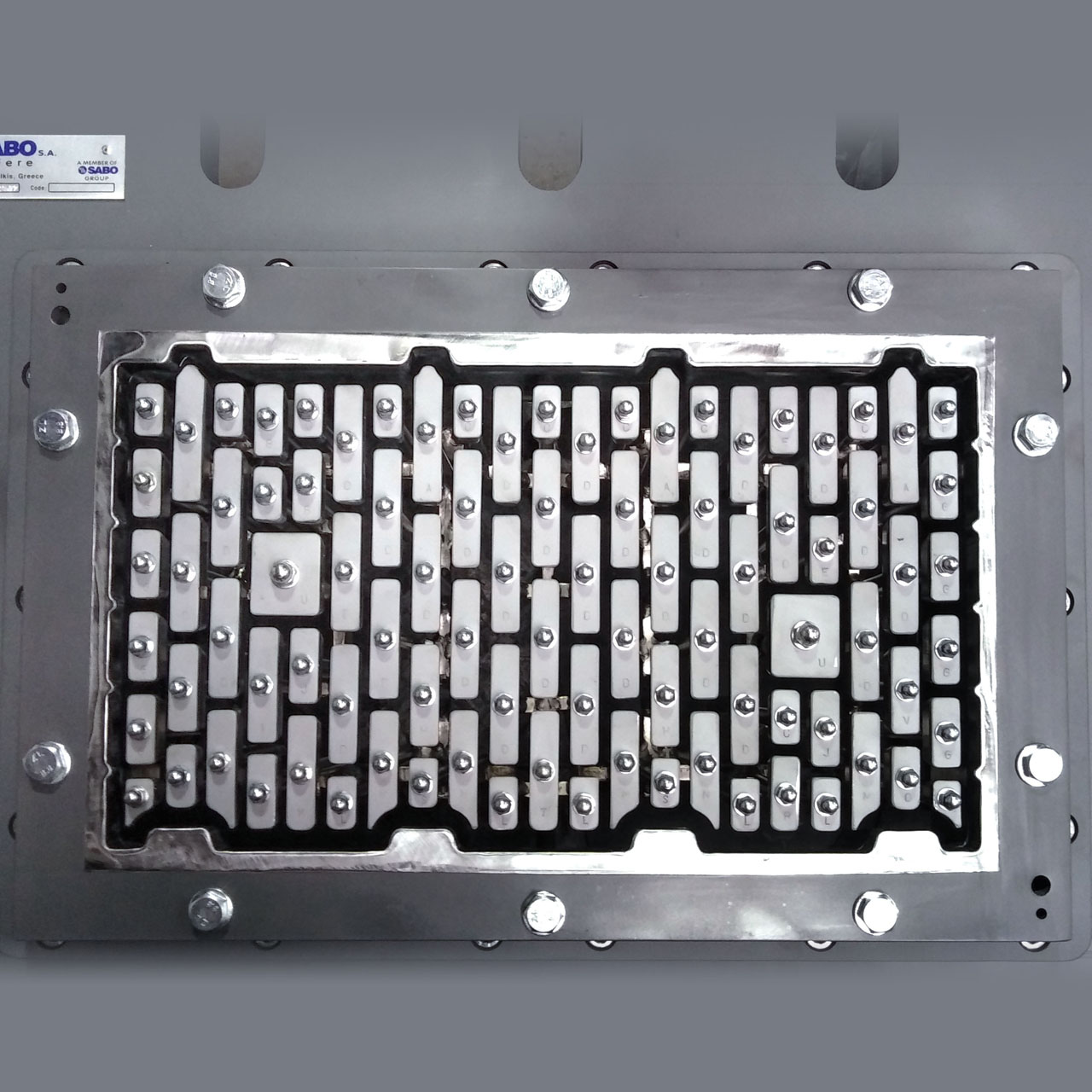

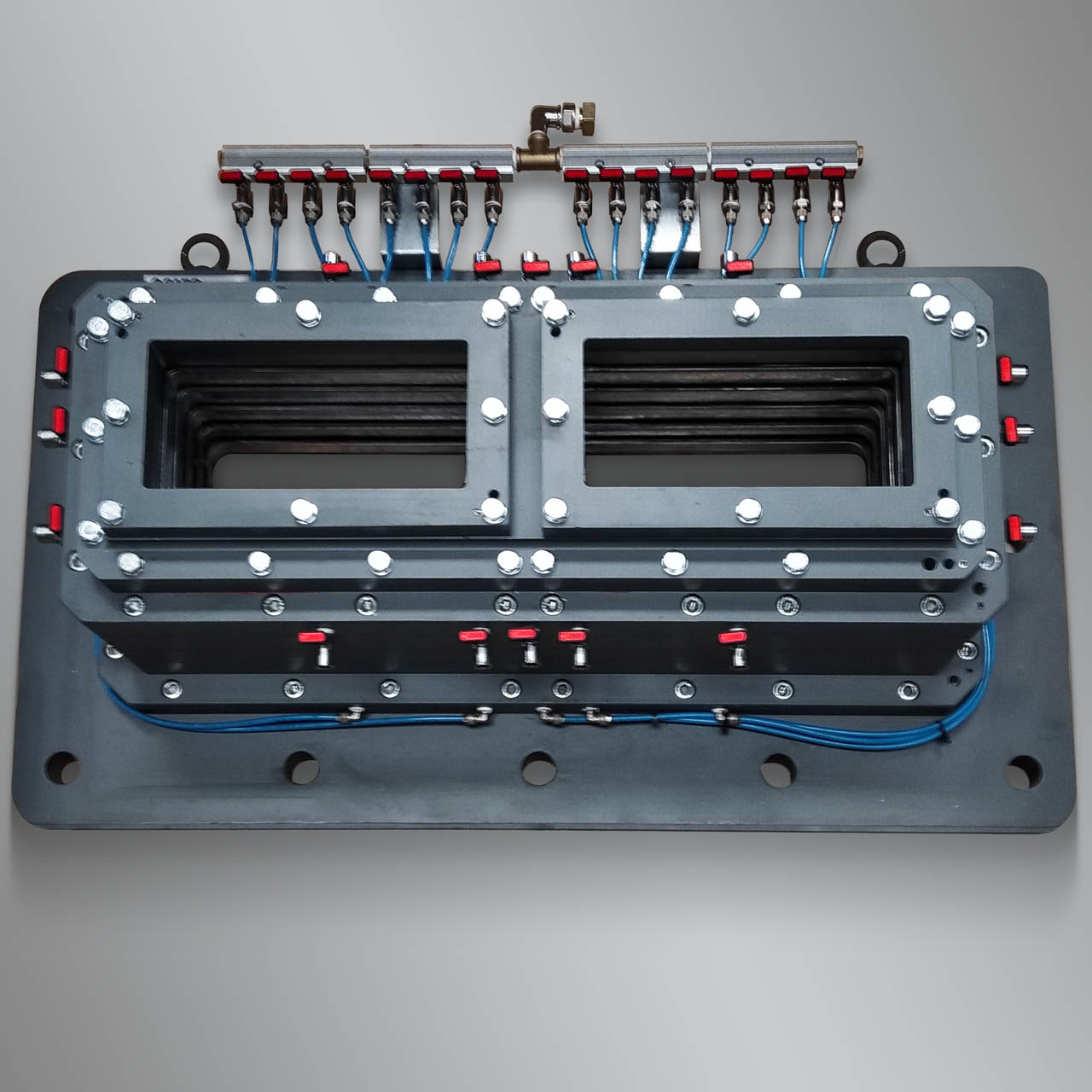

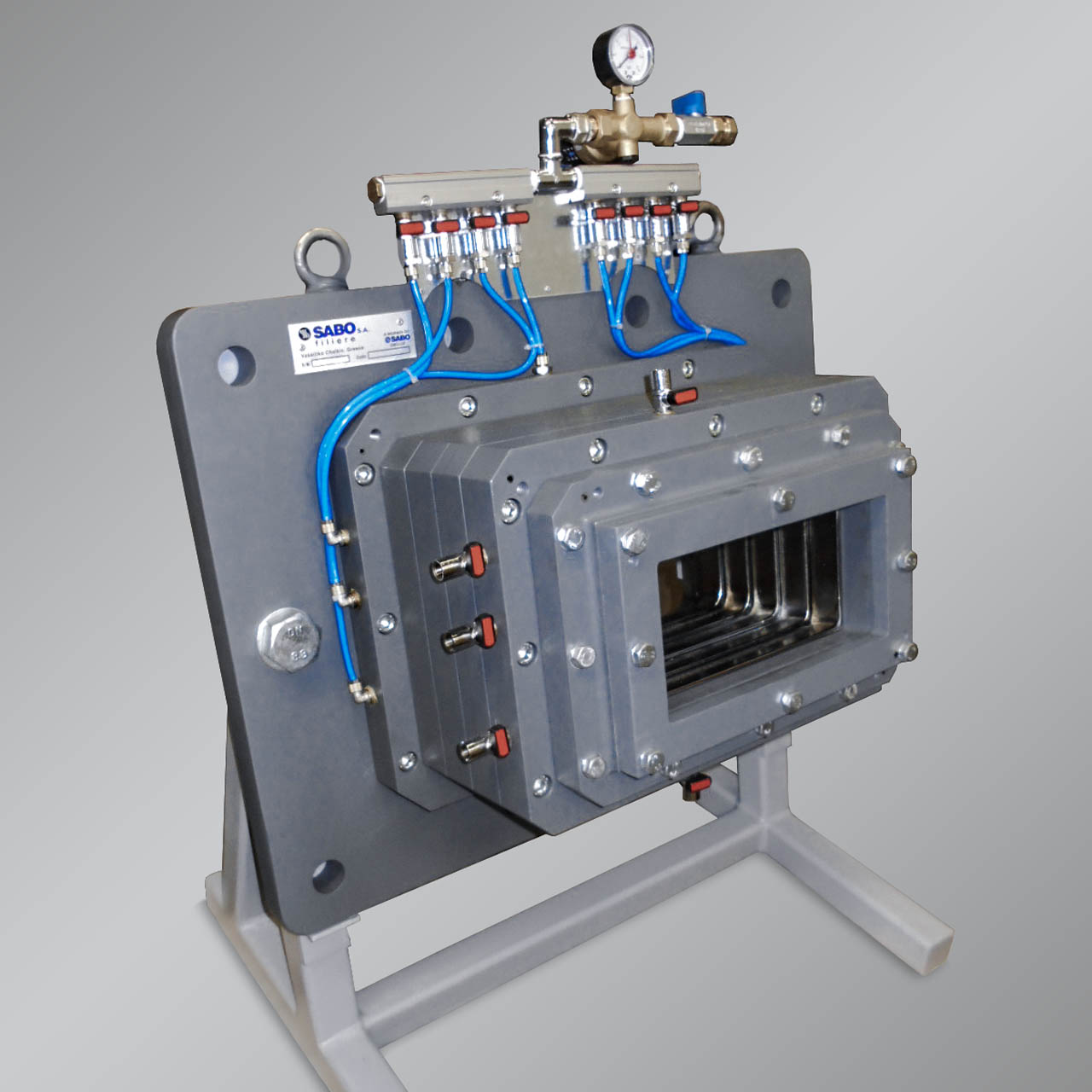

Type SF-LSB

Dies with an extended conical section and an integrated water lubrication system, designed for maximum precision and adaptability. The smart layout of internal water channels allows for independent speed regulation on specific parts of the brick, such as corners and sides, ensuring uniformity, high stability, and superior product quality.

Additional fine-tuning can be achieved through internal brake systems.

General Features:

- Long conical part for enhanced compression and extrusion stability

- Water lubrication system enabling independent speed adjustment of brick corners and sides

- Flexible regulation through internal and external brakes

- Fully replaceable components for smooth and uninterrupted operation

Technical Specifications:

- Metal die body with a combination of hard metal plates and internal protective liners for simplified maintenance

- Liners and bridges made of hardened or hard-chrome-plated steel

- Frame components made of heat-treated steel, ceramics, or tungsten carbide

- Internal brakes with tungsten carbide facing or hard chrome plating