Clay Analysis & Laboratory Services

Υπηρεσίες Εργαστηρίου & Αναλύσεις

Τα εργαστήρια της SABO σε συνεργασία με το Εθνικό Μετσόβιο Πολυτεχνείο (ΕΜΠ), διασφαλίζουν έγκυρα αποτελέσματα και στοχευμένες προτάσεις βελτίωσης. Οι υπηρεσίες των εργαστηρίων μας μπορούν να κατηγοριοποιηθούν ως ακολούθως.

Service Categories:Κατηγορίες

- Raw material clay analysis

- Additives for ceramic mass

- Geological studies

- Thermal insulation properties of ceramic profiles and masonry walls

Raw Material Clay Analysis

A detailed analysis of raw materials and additives is one of the most critical factors in the success of any heavy clay project. At SABO FILIERE, we understand that the quality of raw materials directly affects production performance and the durability of the final product.

This is why our specialized laboratory, in collaboration with the National Technical University of Athens (NTUA), offers a comprehensive evaluation of clay and additives.

The process includes:

- Collection of representative samples of raw materials and additives — either provided by the client or obtained through an on-site visit by our expert team.

- Assessment of quarry suitability and material properties, with forecasts of potential issues that may arise during extrusion, drying, or firing stages.

- Proposal of optimized clay mixtures to enhance product properties and ensure production stability.

- Estimation of material consumption and detailed reporting on the physical properties of the clay, supporting targeted improvements to the final product.

This analysis lays the foundation for high-quality ceramic production, minimizes production costs, and helps prevent unexpected issues on the production line.

Additives in Ceramic Mass

Following the comprehensive laboratory analysis of the base clay material, the SABO FILIERE team leverages its expertise to recommend the most suitable additives that will enhance the properties of the final product.

The selection of additives is never random. We take into account the clay properties, production conditions, and project requirements to propose the ideal solution that:

- Stabilizes product quality

- Reduces production process costs

- Improves performance across all production stages

Key Factors Considered:

- Thermal and acoustic insulation performance of the final product

- Desired appearance (color, texture) to ensure commercial appeal

- Resolution of process-related challenges (drying, firing, etc.)

- Mechanical strength and sensitivity during processing

- Production stability to minimize defective output

Selecting the right additives is a critical step in developing a high-quality product with lower manufacturing costs and superior results in the final market.

Geological Studies

Understanding and evaluating raw material reserves is a critical success factor in any heavy clay project. At SABO FILIERE, we undertake comprehensive geological studies to assess both the quality and quantity of available materials with precision.

Our approach combines traditional geological practices with modern analytical methods, ensuring reliable and complete results.

Our Services Include:

- Drilling and sampling to collect representative raw material specimens

- Evaluation and analysis of raw materials to ensure suitability and quality

- Geological mapping of the deposit area, including graphic representations (maps, layers, cross-sections)

- Estimation of reserve volume and assessment of economic feasibility

- Preparation of a mining study with practical implementation recommendations

Through our geological study, we provide our partners with complete control and confidence in their raw materials, supporting a smooth and efficient production process.

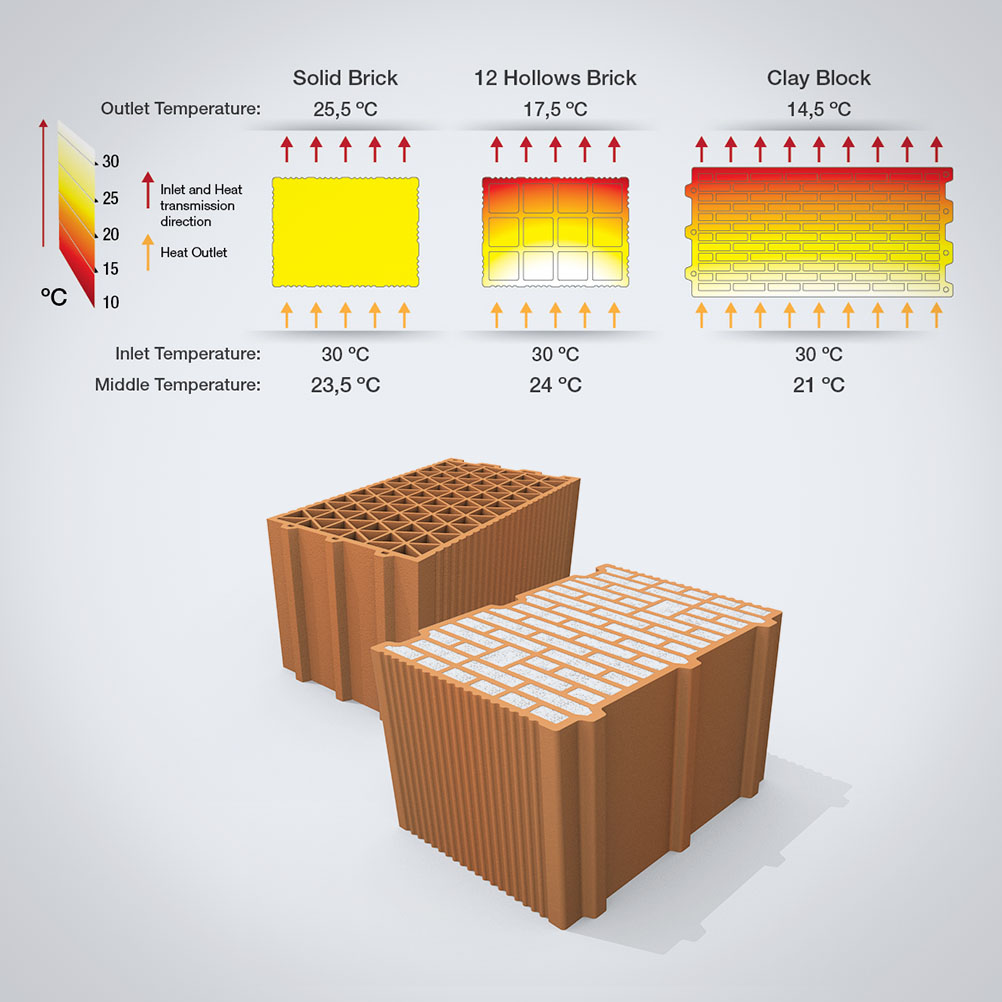

Insulation Properties of Ceramic Profiles & Masonry Walls

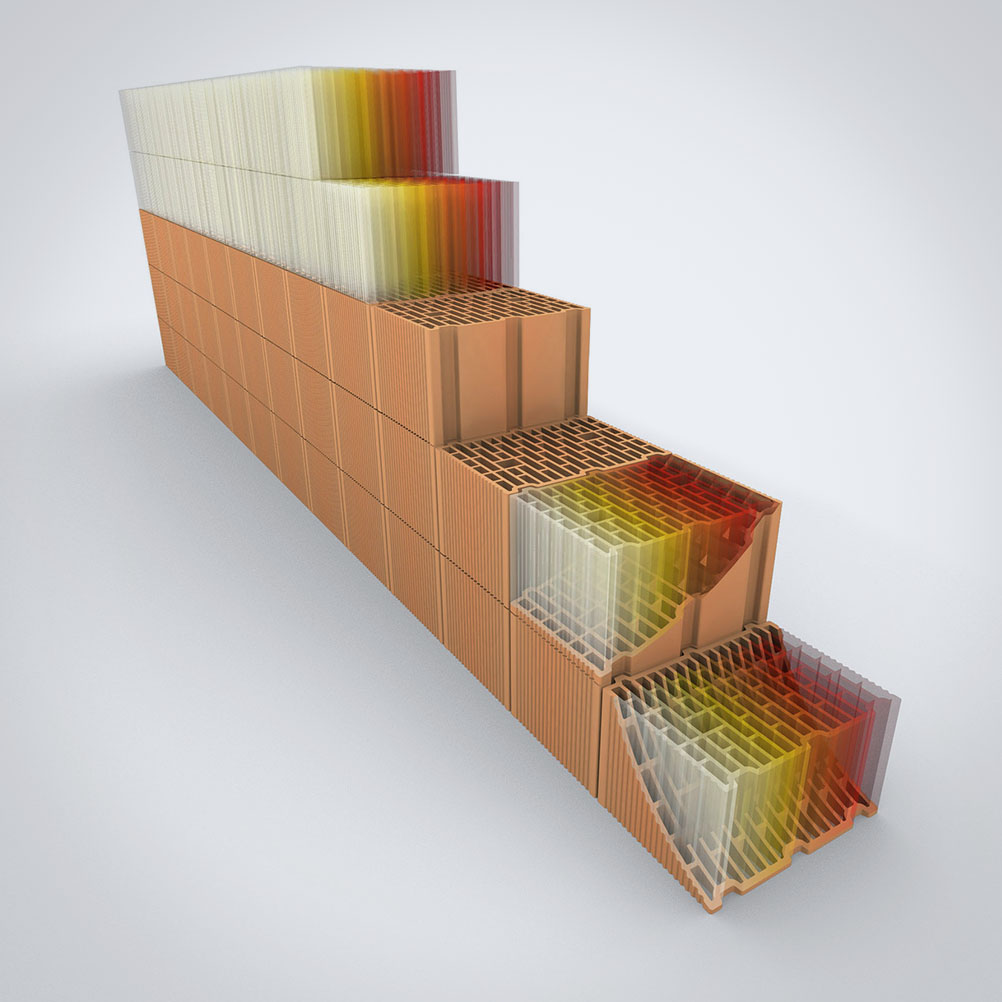

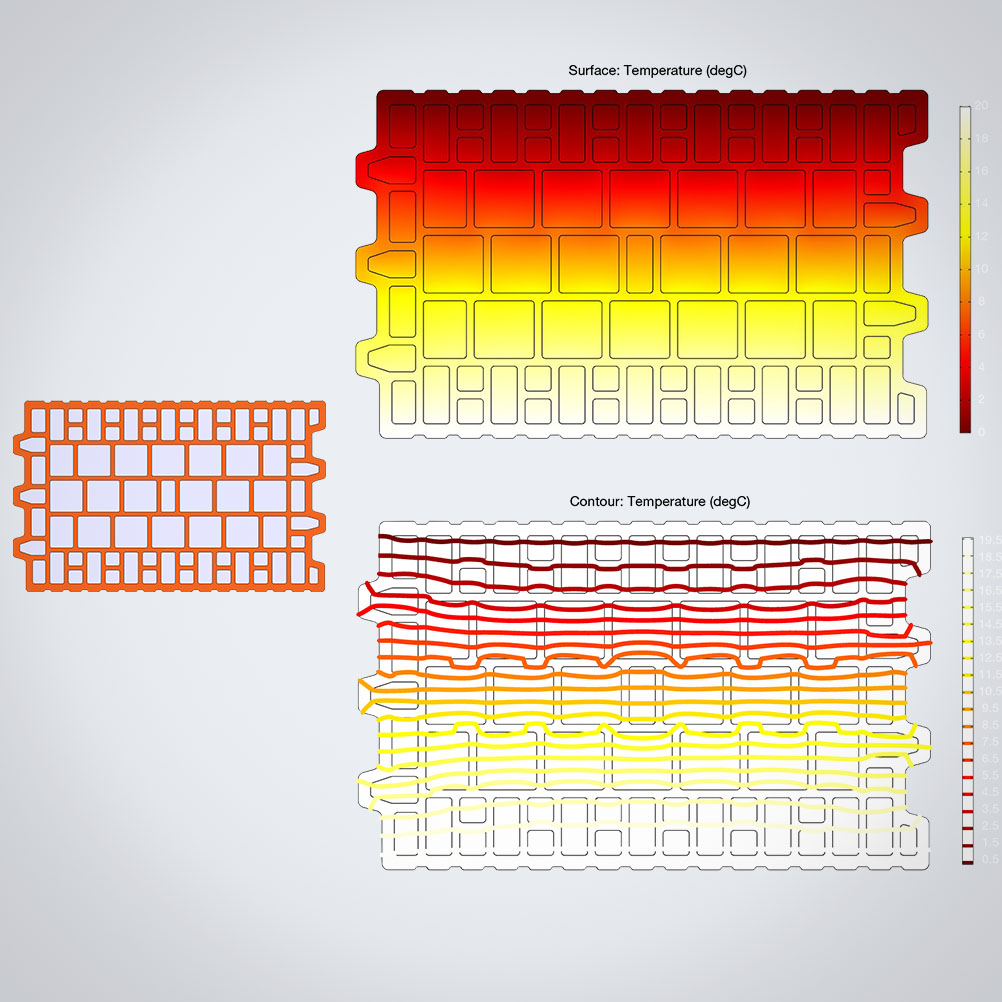

At SABO FILIERE, we provide specialized services for evaluating the thermal and acoustic insulation performance of your ceramic products, aiming to enhance final product characteristics and overall energy efficiency.

The thermal insulation behavior of ceramic profiles—such as bricks and lightweight blocks—is precisely calculated using advanced Computational Fluid Dynamics (CFD) simulations. These simulations are based on internationally recognized standards such as EN 1745, EN ISO 10211:2007, and EN ISO 6946, ensuring a realistic representation of the actual performance of materials under real-world conditions.

In parallel, the acoustic insulation performance of clay bricks and masonry structures is accurately assessed according to DIN 4109-32, complying with the highest soundproofing standards in the industry.

By applying these methodologies, we provide reliable, scientifically backed data that supports the development of high-performance, energy-efficient ceramic products, tailored to the evolving needs of global markets.